Agc System For Hot/Cold Strip Rolling Mill

Feb . 17, 2025 13:33

Back to list

Agc System For Hot/Cold Strip Rolling Mill

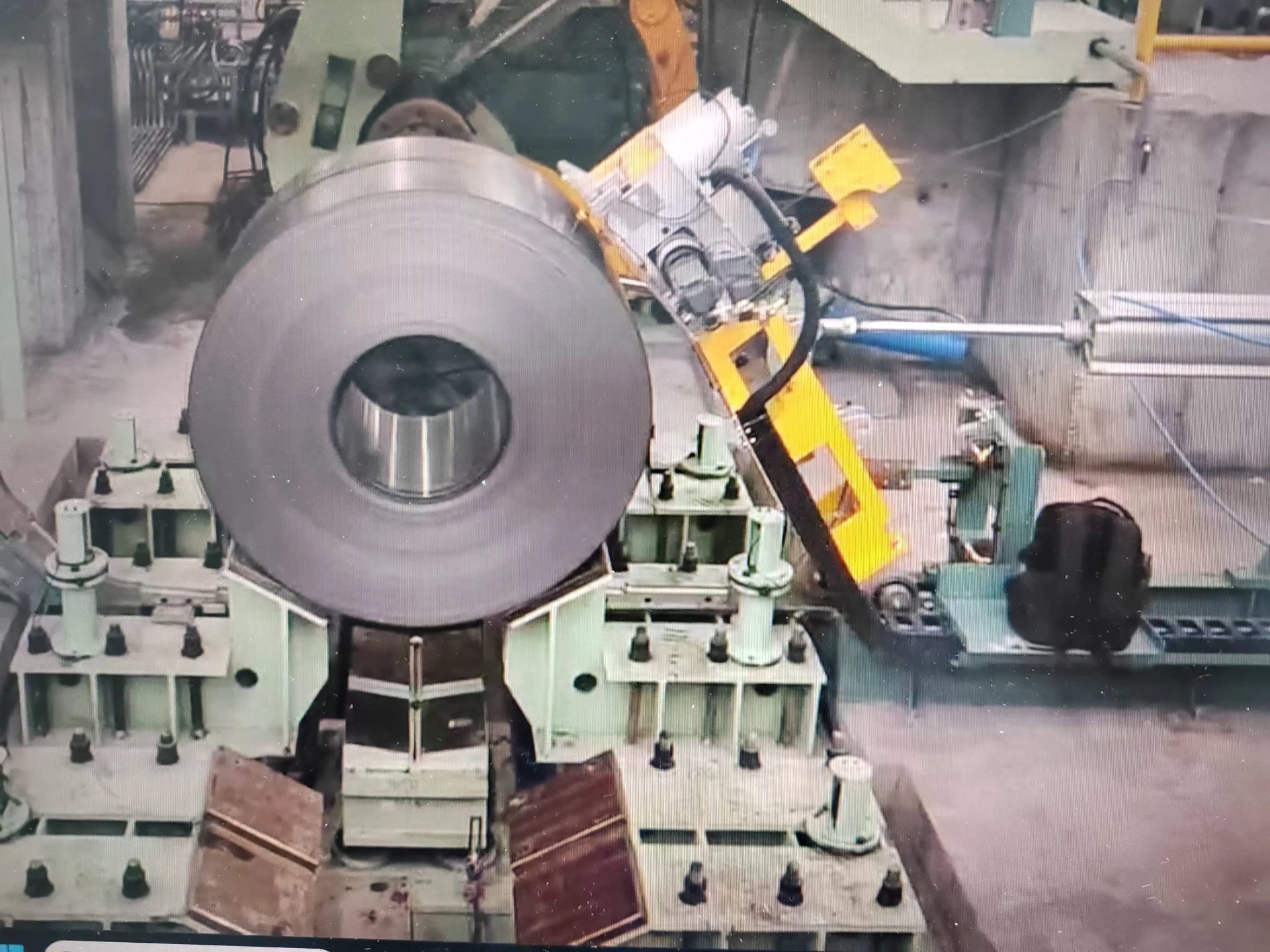

In the world of metal processing, the 3000 kN skin pass mill stands as a cornerstone of quality and efficiency. This specialized machine, capable of imparting surface smoothness and precise material properties, embodies a blend of engineering innovation and metallurgical expertise. As more industries lean towards high precision metal products, understanding the nuances and capabilities of this equipment becomes crucial. In this article, we delve into the complexities and benefits of the 3000 kN skin pass mill, highlighting its pivotal role in modern metal manufacturing.

Adopting a 3000 kN skin pass mill also aligns with sustainable practices. By improving surface quality and mechanical properties in a single pass, it reduces the need for additional processing, conserving energy and minimizing waste. Moreover, the mindful design of this machinery promotes longevity and low maintenance, reducing operational costs over time. Companies can thus achieve a balance between high-quality output and environmentally sound practices, which is increasingly important in today’s market. Industry Applications The versatility of the 3000 kN skin pass mill extends to various applications. In the automotive sector, it enables the production of steel sheets with perfect surface characteristics crucial for coating and painting processes. In household appliances, it ensures the manufacture of robust, aesthetically pleasing metal components. Furthermore, in the construction industry, materials are treated to withstand external elements while maintaining a visually appealing facade. Expertise and Authority The development and implementation of the 3000 kN skin pass mill are backed by years of expertise in metallurgical engineering. Manufacturers and technicians operating this sophisticated machinery are often required to possess exceptional skills, ensuring each process enhances the material as intended. This knowledge-driven approach bolsters the machine's authority and reliability in producing premium metal sheets. Trust through Transparency For those considering investing in a 3000 kN skin pass mill, transparency in operational capabilities and potential returns on investment are vital. Reputable manufacturers offer detailed consultations, performance demonstrations, and comprehensive maintenance guides to foster trust and long-lasting relationships with clients. These practices ensure clients are fully informed and confident in their equipment, contributing to a seamless integration into their production lines. In conclusion, the 3000 kN skin pass mill represents a fusion of technological precision and expert craftsmanship essential for advancing today's metallurgical standards. Its ability to enhance both the aesthetic and functional attributes of metal products positions it as a leader in the pursuit of quality-driven manufacturing. As industries continue to evolve, the demand for such precision-oriented machinery will undoubtedly rise, reinforcing its status as an integral component of modern production facilities.

Adopting a 3000 kN skin pass mill also aligns with sustainable practices. By improving surface quality and mechanical properties in a single pass, it reduces the need for additional processing, conserving energy and minimizing waste. Moreover, the mindful design of this machinery promotes longevity and low maintenance, reducing operational costs over time. Companies can thus achieve a balance between high-quality output and environmentally sound practices, which is increasingly important in today’s market. Industry Applications The versatility of the 3000 kN skin pass mill extends to various applications. In the automotive sector, it enables the production of steel sheets with perfect surface characteristics crucial for coating and painting processes. In household appliances, it ensures the manufacture of robust, aesthetically pleasing metal components. Furthermore, in the construction industry, materials are treated to withstand external elements while maintaining a visually appealing facade. Expertise and Authority The development and implementation of the 3000 kN skin pass mill are backed by years of expertise in metallurgical engineering. Manufacturers and technicians operating this sophisticated machinery are often required to possess exceptional skills, ensuring each process enhances the material as intended. This knowledge-driven approach bolsters the machine's authority and reliability in producing premium metal sheets. Trust through Transparency For those considering investing in a 3000 kN skin pass mill, transparency in operational capabilities and potential returns on investment are vital. Reputable manufacturers offer detailed consultations, performance demonstrations, and comprehensive maintenance guides to foster trust and long-lasting relationships with clients. These practices ensure clients are fully informed and confident in their equipment, contributing to a seamless integration into their production lines. In conclusion, the 3000 kN skin pass mill represents a fusion of technological precision and expert craftsmanship essential for advancing today's metallurgical standards. Its ability to enhance both the aesthetic and functional attributes of metal products positions it as a leader in the pursuit of quality-driven manufacturing. As industries continue to evolve, the demand for such precision-oriented machinery will undoubtedly rise, reinforcing its status as an integral component of modern production facilities.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products