Cold Rolled Stainless Steel Strip - High Precision, Durable Quality from Leading Manufacturer

- Introduction and Significance of Cold Rolled Stainless Steel Strip

- Data-Driven Overview of Global Market Trends

- Technological Advantages of Cold Rolling Processes

- Comparative Analysis of Leading Stainless Steel Manufacturers

- Custom Solutions and Tailoring for Industry Needs

- Practical Applications with Real-World Case Studies

- Conclusion: The Future of Cold Rolled Stainless Steel Strip

(نوار فولاد ضد زنگ نورد سرد)

Introduction and Significance of Cold Rolled Stainless Steel Strip

The modern industrial landscape is heavily reliant on quality materials, and نوار فولاد ضد زنگ نورد سرد

(cold rolled stainless steel strip) stands out as a material of choice across wide-ranging sectors. Its unique combination of precision, durability, and consistency makes it indispensable in manufacturing, construction, automotive, electronics, and numerous high-performance applications.

Unlike hot rolled counterparts, cold rolled strips boast improved surface finishes, tighter tolerances, and enhanced mechanical properties through progressive processing. This has positioned cold rolled stainless steel strips as foundational elements for advanced engineering and design. The synergy between these base materials, advanced processing technologies, and end-user requirements continues to drive innovation within the supply chain, influencing everything from product lifetime to cost control.

Data-Driven Overview of Global Market Trends

The worldwide market for cold rolled stainless steel strip has witnessed exponential growth over the last decade. According to a 2023 market report by Grand View Research, global stainless steel demand reached approximately 56.1 million metric tons, with cold rolled products accounting for nearly 35% of this volume.

A regional breakdown places Asia Pacific at the forefront, contributing more than 70% to production and consumption, primarily dominated by China, India, and Japan. Europe, with its advanced engineering industries, consistently demonstrates high-value utilization, while North America remains a robust importer and consumer, especially in medical devices and automotive components.

The cold rolled segment, driven by the push toward lightweighting and high-strength components, is expected to grow at a CAGR of 4.8% through 2030. Sustainability initiatives and circular economy principles further encourage adoption, highlighting the eco-friendly lifecycle of stainless products—over 85% of which are recyclable.

Technological Advantages of Cold Rolling Processes

The cold rolling of stainless steel strips involves reductive processing at ambient temperatures, providing unmatched precision and yielding a superior product to traditional hot rolling. Key technical advantages include:

- Superior Surface Quality: The cold rolling process imparts an optimal finish, often measured at Ra ≤ 0.2 μm without the need for extensive post-polishing, crucial for industries demanding stringent hygiene.

- Tighter Tolerances: Precision thickness control, with deviations often less than ±0.01 mm, ensures consistent form and function across large-scale batches.

- Improved Mechanical Properties: Enhanced tensile strength—frequently exceeding 700 MPa for austenitic alloys—makes these strips suitable for dynamic loading environments.

- Work Hardening: Strategic cold working increases hardness and yield strength, supporting applications in springs and fasteners.

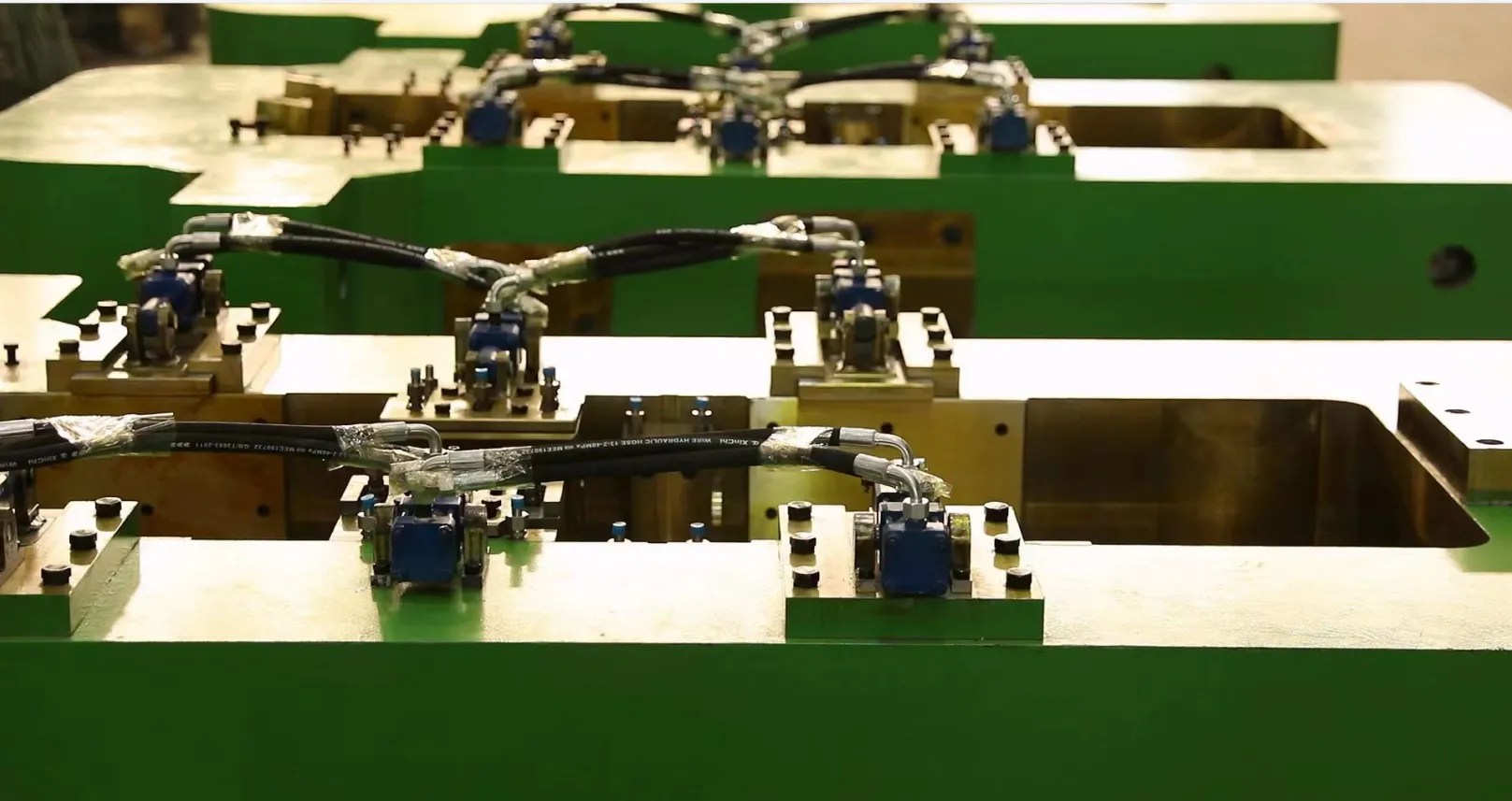

Modern آسیاب نورد فولاد ضد زنگ (stainless steel rolling mills) have embraced fully automated gauges, real-time adjustment systems, and cleanroom production, mitigating contamination and ensuring uniformity. These advancements underpin the growing preference for cold rolled solutions in sectors demanding reliability and traceability.

Comparative Analysis of Leading Stainless Steel Manufacturers

The global arena for cold rolled stainless steel strip production features prominent names such as Outokumpu, Aperam, Jindal Stainless, POSCO, and TISCO. These کارخانه های فولاد ضد زنگ (stainless steel factories) leverage proprietary technology, supply chain integration, and a robust quality ethos to meet diverse client specifications.

| Manufacturer | Annual Capacity (MT) | Surface Finish Options | Gauge Range (mm) | Key Industry Served | Certifications |

|---|---|---|---|---|---|

| Outokumpu | 2,700,000 | 2B, BA, 2D, Mirror | 0.1–4.0 | Automotive, Construction | ISO 9001, ISO 14001 |

| Aperam | 2,500,000 | 2B, BA, Satin, No.4 | 0.15–3.5 | Medical, Precision Components | ISO 9001, IATF 16949 |

| POSCO | 2,000,000 | 2B, BA, HL, Chequered | 0.2–3.2 | Household Appliances | ISO 9001, OHSAS 18001 |

| Jindal Stainless | 1,600,000 | 2B, BA, Wet Polished | 0.1–6.0 | Railway, Architecture | ISO 9001, ISO 50001 |

Buyers differentiate suppliers based on quality pedigree, logistic reach, R&D support, and consignment flexibility. European producers tend towards specialized alloys and advanced surface specifications, whereas Asian mills often emphasize volume and cost competitiveness. The ability to handle custom widths and rapid shift in alloy grades also ranks highly among procurement priorities.

Custom Solutions and Tailoring for Industry Needs

Today’s competitive market environment underscores the importance of manufacturer flexibility. Leading stainless steel strip producers frequently offer custom alloy development, exacting width and thickness control (down to 0.01 mm increments), and specialized surface treatments, aligning with unique industry challenges.

For end users in aerospace and medical sectors, for instance, the ability to specify ultra-flatness and customized microstructure is crucial for mission-critical performance. Automotive clients may request dual-phase or precipitation-hardened options to achieve weight reduction without sacrificing strength.

- Cut-to-Length Services: Minimizes downstream waste by delivering materials pre-sized for final manufacturing operations.

- Surface Customization: Tailoring from matte to high gloss or embossed textures, supporting both functional and aesthetic needs.

- Alloy Expertise: In-house metallurgists support rapid prototyping and standard compliance, speeding up product development cycles.

This degree of customization has shortened lead times by up to 25% while offering a 15–20% reduction in overall scrap and rework rates, delivering tangible cost advantages for high-mix, low-volume manufacturing environments.

Practical Applications with Real-World Case Studies

The transformative impact of cold rolled stainless steel strip resonates across diverse industries. Here are select application highlights:

- Automotive Sector: A global automotive manufacturer implemented 301 grade cold rolled strips to construct high-yield seat belt buckles. Switching from traditional carbon steel, the strip’s elevated tensile strength increased product lifecycle by 18%, while the upgraded surface finish reduced friction wear.

- Electronics: A leader in mobile devices adopted ultra-thin (0.1 mm) stainless steel strip as EMI shielding for next-generation smartphones. The cold rolled product ensured uniform conductivity and maintained tolerance within ±3 μm, cutting assembly time by 12%.

- Medical Devices: Surgical instrument manufacturers shifted to cold rolled strips for blades and springs. The hypoallergenic properties and micro-finished surfaces exceeded ISO 10993-1 standards, leading to a 27% drop in post-production surface defects.

These examples underscore the ability of custom cold rolled strips to answer evolving market demands in performance, safety, and precision. From tiny connectors to architectural elements, versatility is a hallmark of this product.

Conclusion: The Future of Cold Rolled Stainless Steel Strip

In summary, نوار فولاد ضد زنگ نورد سرد remains a linchpin material powering modern development across industries. As کارخانه های فولاد ضد زنگ (stainless steel factories) invest in next-gen rolling technologies and advanced quality control, end-users can expect higher standards of customization, sustainability, and reliability. The convergence of data-driven decision-making, technical partnerships, and dynamic application requirements ensures that cold rolled stainless steel strip will continue to shape the technological and economic landscape for decades to come.

(نوار فولاد ضد زنگ نورد سرد)

FAQS on نوار فولاد ضد زنگ نورد سرد

Q: What is cold rolled stainless steel strip?

A: Cold rolled stainless steel strip is a thin, flat product made from stainless steel, processed at room temperature. This method increases its strength and improves its surface finish. It is widely used in various industrial applications.Q: What are the main benefits of using cold rolled stainless steel strip?

A: The main benefits include higher strength, improved surface quality, and better dimensional accuracy. Cold rolling also enhances corrosion resistance. These properties make it suitable for precise manufacturing needs.Q: How does a stainless steel rolling mill operate?

A: A stainless steel rolling mill processes steel by compressing it between rollers at controlled temperatures. This forms thin sheets or strips with desired properties. The process ensures uniform thickness and quality.Q: What products do stainless steel factories typically produce?

A: Stainless steel factories usually produce sheets, strips, coils, rods, and tubes. These products are tailored for different industrial and commercial uses. The factories ensure high quality and standardization.Q: Why is cold rolled stainless steel strip preferred in certain applications?

A: It is preferred for its superior mechanical properties and smooth surface finish. It meets high precision and aesthetic requirements in industries like electronics and automotive. Its quality makes it a top choice.-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025