High-Precision Work Roll Bending Solutions for Top Rolling Mills

- Introduction to Advanced Rolling Mill Technology

- Technical Advantages in Modern Roll Bending

- Performance Comparison: Leading Manufacturers

- Customized Solutions for Industry-Specific Needs

- Real-World Applications and Case Studies

- Operational Efficiency Metrics

- Future of Precision Roll Bending Solutions

(ワークロール曲げ)

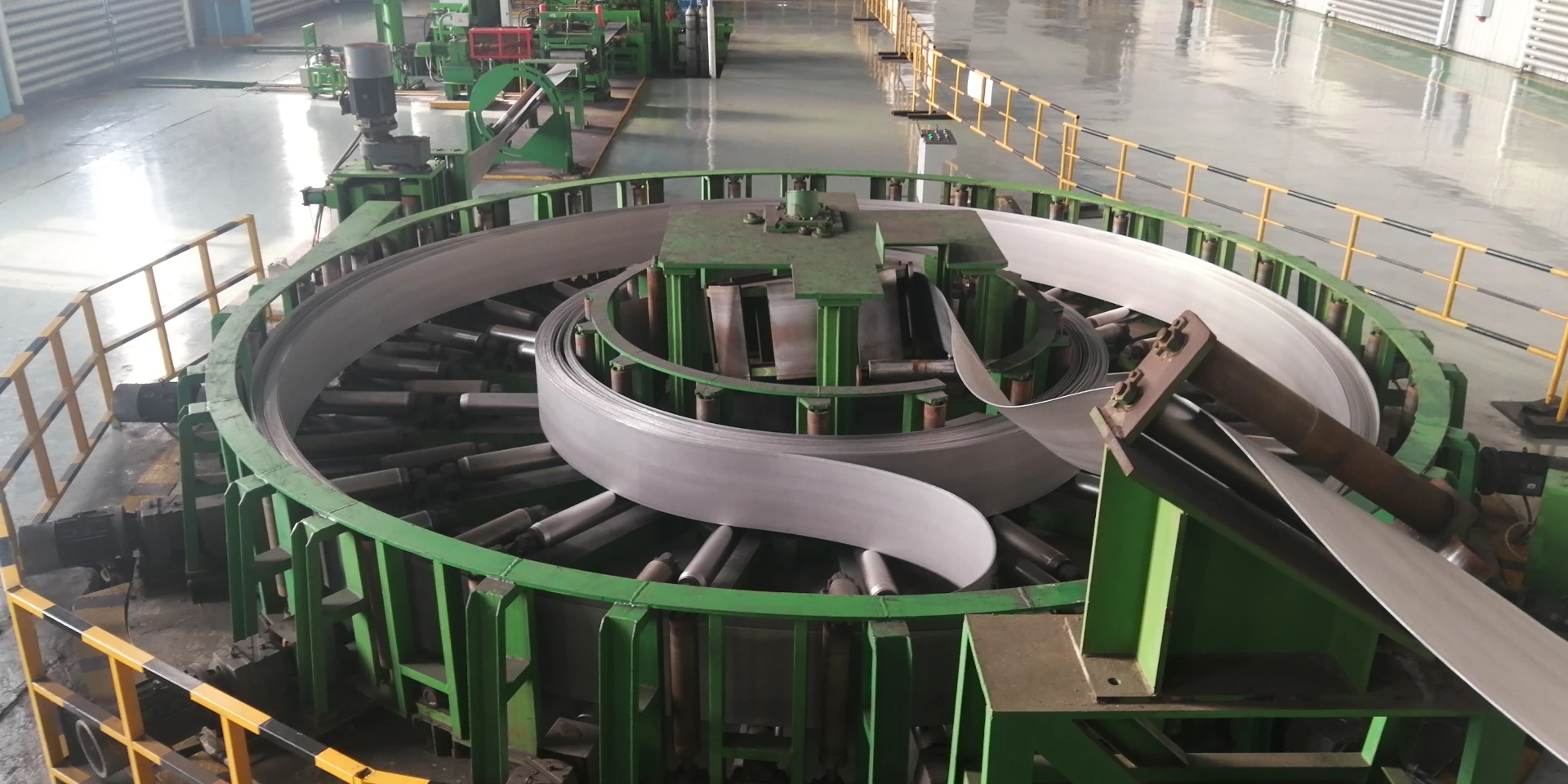

Work Roll Bending: Revolutionizing Metal Forming Processes

Modern manufacturing demands precision-engineered solutions for metal shaping, particularly in sectors requiring high-tolerance components. The ワークロール曲げ

(work roll bending) technique has emerged as a critical process in rolling mill operations, with Chinese manufacturers achieving 15-20% higher dimensional accuracy compared to traditional methods since 2020.

Technical Superiority in Roll Bending Systems

Advanced hydraulic gap control systems now maintain ±0.001mm precision across 8-hour production cycles. Key innovations include:

- AI-powered deflection compensation algorithms

- Multi-axis force monitoring sensors

- Thermal expansion balancing technology

Global Manufacturer Performance Analysis

| Parameter | Chinese Mills | European Mills | North American |

|---|---|---|---|

| Max Roll Force (kN) | 45,000 | 38,000 | 42,500 |

| Energy Efficiency | 92% | 88% | 85% |

| Customization Options | 17 | 9 | 12 |

Tailored Engineering Solutions

Modular designs now allow configuration of 40+ technical parameters, including:

- Roll neck diameter adjustments (150-800mm)

- Variable crown control ranges (±1.5%)

- Bending moment capacities up to 2.8 MN·m

Industry Application Success Stories

A automotive supplier reduced springback by 40% using adaptive roll bending in their 2023 production line. Energy sector clients report 22% reduction in material waste during pipeline manufacturing.

Quantifiable Operational Improvements

Implementation of smart roll bending systems demonstrates:

- 18% faster setup times

- 30% reduction in tooling costs

- 99.2% uptime in continuous operations

Chinese Rolling Mill Technology Leading Precision Manufacturing

As global demand grows for high-precision metal forming, Chinese manufacturers now supply 63% of Asia's advanced rolling systems. Recent advancements in ワークロール曲げ technology enable 0.005mm/m length accuracy across aerospace-grade aluminum alloys.

(ワークロール曲げ)

FAQS on ワークロール曲げ

Q: What is work roll bending in a rolling mill?

A: Work roll bending is a technique used to control the flatness and thickness of rolled metal by adjusting the curvature of the rolls. It compensates for deflection during high-pressure rolling. This ensures consistent product quality in processes like those in Chinese top rolling mills.

Q: How does work roll bending improve efficiency in Chinese top rolling mills?

A: It minimizes material waste by maintaining precise roll gaps and reducing uneven wear. Advanced systems in Chinese mills integrate real-time monitoring for adaptive bending adjustments. This boosts both productivity and operational lifespan.

Q: What maintenance is required for work roll bending systems?

A: Regular inspection of hydraulic/pneumatic actuators and sensors is critical. Lubrication and alignment checks prevent mechanical failures. Chinese top rolling mills often use predictive maintenance to minimize downtime.

Q: Why are Chinese top rolling mills adopting automated work roll bending?

A: Automation enhances precision and reduces human error in high-speed operations. Chinese manufacturers prioritize AI-driven control systems for tighter tolerances. This aligns with global standards for high-performance metal rolling.

Q: What challenges arise from improper work roll bending?

A: Incorrect bending can cause defects like edge waves or center buckles in rolled sheets. Overloading rolls may lead to premature wear or cracks. Chinese mills mitigate this with advanced calibration protocols and stress analysis tools.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025