Steel Rolling Rods High-Precision Rolling Machines & Equipment

- Introduction to Rolling Mill Technology in Modern Manufacturing

- Technical Advantages of Advanced Rolling Mill Equipment

- Comparative Analysis of Leading Rolling Mill Manufacturers

- Customized Solutions for Steel Rolling Mill Operations

- Real-World Applications and Success Stories

- Future Trends in Rolling Mill Machinery Innovation

- Why Invest in High-Performance Rolling Mill Systems

(میله نورد)

Introduction to Rolling Mill Technology in Modern Manufacturing

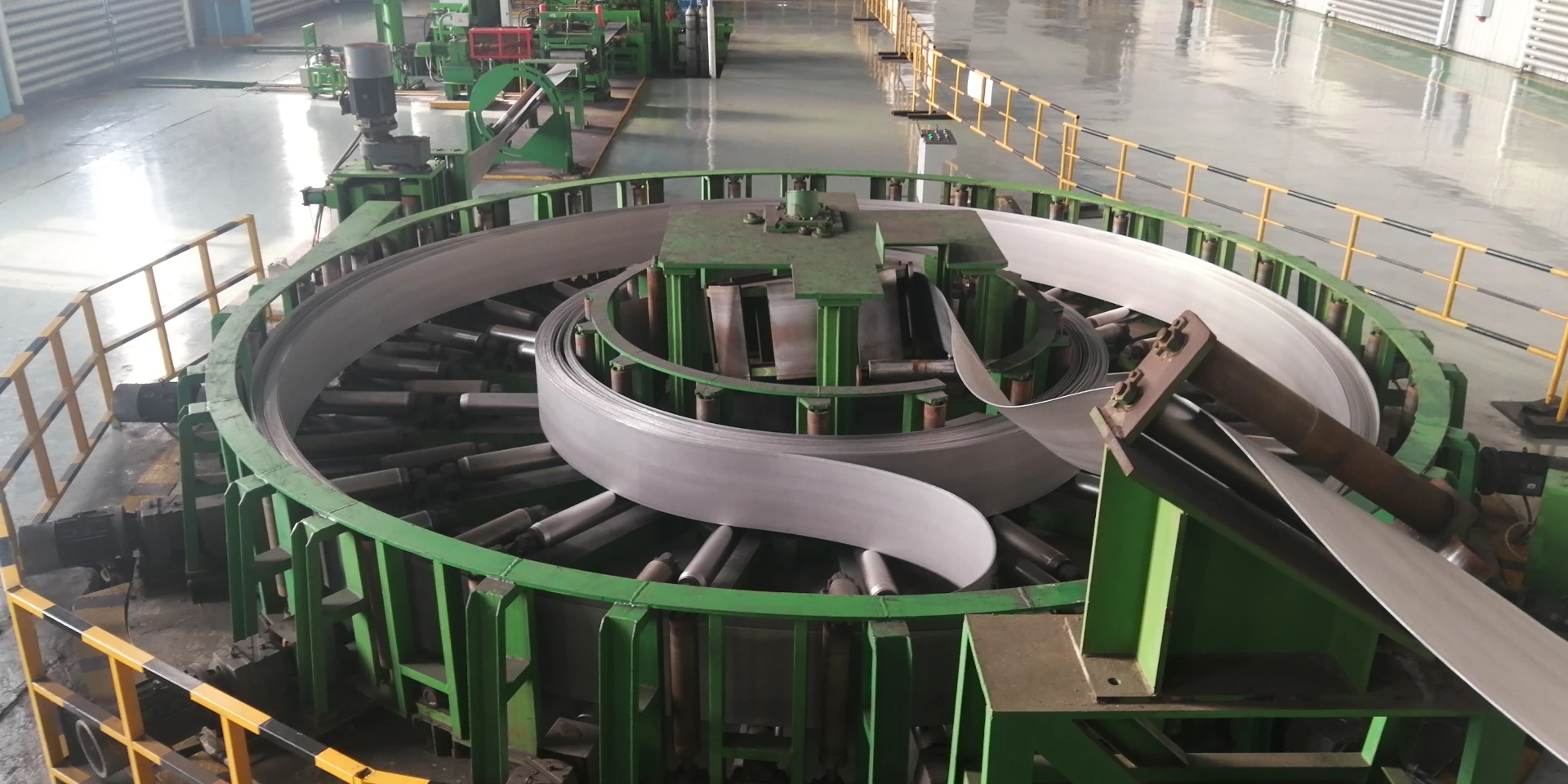

Rolling mill technology, particularly steel rolling mill equipment, has become the backbone of metal fabrication industries. These systems transform raw steel into precise rods, bars, and wires, meeting rigorous industrial standards. With global demand for steel products projected to grow by 3.8% annually through 2030, efficient bar and wire rod rolling mills are critical for maintaining supply chains and reducing production costs.

Technical Advantages of Advanced Rolling Mill Equipment

Modern rolling mill machines integrate automation, precision engineering, and energy-efficient designs. Key features include:

- 90%+ uptime reliability due to reinforced alloy components

- 30% faster production speeds compared to legacy systems

- 15-20% energy savings via regenerative braking technology

Advanced sensors enable real-time thickness adjustments within ±0.05mm, ensuring consistent output for high-value applications like automotive parts and construction materials.

Comparative Analysis of Leading Rolling Mill Manufacturers

| Manufacturer | Automation Level | Annual Capacity (tons) | Energy Use (kWh/ton) | Customization |

|---|---|---|---|---|

| TechRoll Pro | Grade 4 | 500,000 | 45 | Full |

| SteelMaster | Grade 3 | 350,000 | 58 | Partial |

| MetaRoll X | Grade 4.5 | 650,000 | 42 | Full |

Customized Solutions for Steel Rolling Mill Operations

Leading suppliers now offer modular rolling mill systems tailored to specific production needs. A Middle Eastern client reduced scrap rates by 22% after adopting a hybrid configuration combining continuous casting with inline heat treatment. Customizable parameters include:

- Roll diameter (100mm–800mm)

- Material compatibility (carbon steel, stainless, alloys)

- Output formats (round bars, hexagonal wires, flat strips)

Real-World Applications and Success Stories

A Southeast Asian automotive parts manufacturer achieved ROI within 14 months by upgrading to a smart steel rod rolling mill. The system’s predictive maintenance algorithms reduced unplanned downtime by 40%, while dynamic speed control increased yield by 18% on high-margin specialty steels.

Future Trends in Rolling Mill Machinery Innovation

Emerging technologies like AI-powered quality detection and hydrogen-fired reheating furnaces are set to revolutionize rolling mill operations. Pilot projects show 25% reductions in carbon emissions and 12% improvements in material utilization through machine learning optimization.

Why Invest in High-Performance Rolling Mill Systems

For manufacturers prioritizing scalability and precision, advanced bar and wire rod rolling mills deliver unmatched ROI. With proper maintenance schedules, these systems maintain 95%+ efficiency for over 15 years, making them indispensable for competitive metal processing workflows.

(میله نورد)

FAQS on میله نورد

Q: What is a rod rolling process used for in metalworking?

A: The rod rolling process shapes metal into cylindrical rods by passing it through rotating rollers. It ensures precise dimensions and improves material properties like strength. This method is widely used in producing steel rods for construction and manufacturing.

Q: How does a rod rolling machine work?

A: A rod rolling machine uses sequential rollers to compress and elongate heated metal billets into rods. The rollers adjust thickness and surface finish incrementally. This automation ensures efficient, high-volume production of uniform rods.

Q: What industries use steel rod rolling machines?

A: Steel rod rolling machines are vital in construction, automotive, and infrastructure industries. They produce reinforcement bars, wires, and structural components. These rods are essential for frameworks, cables, and machinery parts.

Q: What are the advantages of modern rod and wire rod rolling systems?

A: Modern systems offer enhanced precision, energy efficiency, and reduced material waste. They support customizable rod diameters and faster production rates. Advanced controls also minimize manual intervention and errors.

Q: How to maintain a steel rod rolling machine?

A: Regular lubrication, roller alignment checks, and wear inspections are critical. Cleaning debris and monitoring temperature controls prevent breakdowns. Scheduled maintenance ensures longevity and consistent output quality.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025