テンパー圧延ミル

Mar . 07, 2025 01:22

Back to list

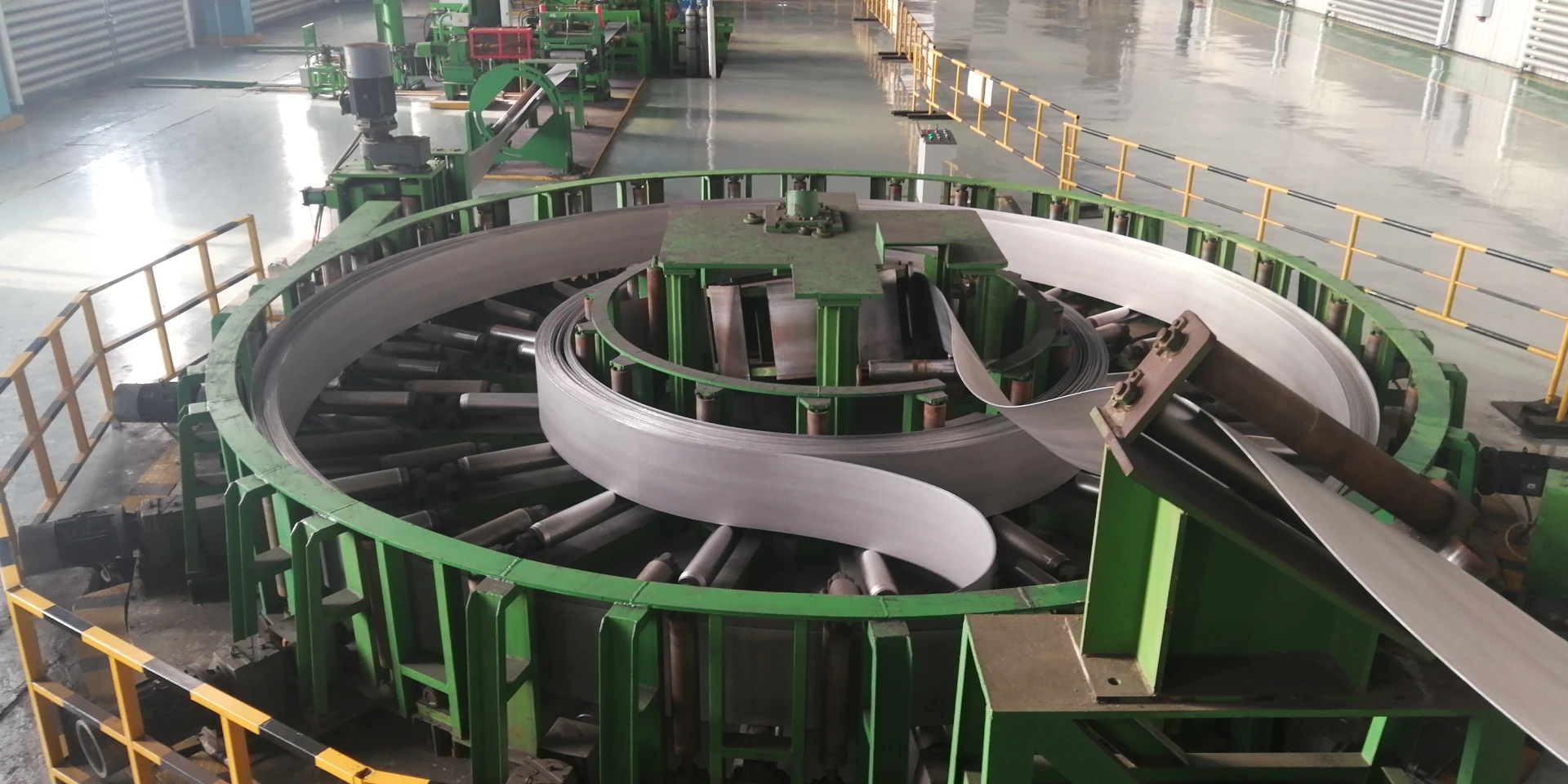

テンパー圧延ミル

The temper rolling mill, a pivotal instrument in the metalworking industry, is renowned for enhancing the quality and performance of final metal products. Being at the forefront of steel processing technology, these mills have become indispensable in industries that demand high precision and superior strength products.

Authoritativeness The temper rolling mill is not just a machine; it epitomizes the pinnacle of metallurgy and mechanical engineering expertise. Many industrial bodies and academic institutions have conducted extensive research on how temper rolling affects metal properties. Studies have illustrated that temper rolling can significantly improve flatness and surface texture, which are critical for applications requiring tight aesthetic and functional specifications. The mill’s capability to enhance anti-corrosive properties by refining the grain structure of the metal is widely documented in metallurgical journals. Additionally, industry experts regularly confer about the optimum settings for various metals to achieve desired outcomes. This ongoing dialogue among professionals is testament to the authority that temper rolling mills command in the industry. Manufacturers of temper rolling mills continue to innovate, frequently enhancing their equipment's capabilities, thus solidifying their standing as leaders in metal processing solutions. Trustworthiness The reputation of temper rolling mills is supported by a robust foundation of trust built over decades of consistent performance in metal refining. Customers from industries such as automotive, aerospace, and construction rely heavily on the quality assurance that these mills provide. When precision and reliability are paramount, the temper rolling mill becomes the trusted choice. Companies often showcase certifications and compliance with international steel quality standards as testament to the trustworthiness of their products processed through temper rolling techniques. Furthermore, the manufacturers of these mills offer comprehensive support and maintenance services, ensuring that their machines operate at peak efficiency and reliability. Many companies also provide training programs to ensure that operators are well-versed in the operation and maintenance of the machinery, which in turn reinforces the trust in the product’s reliability. In conclusion, temper rolling mills stand out in the metalworking sector for their ability to enhance product quality while maintaining dimensional precision. Their role is undisputed among professionals who demand the highest standards in their metal products, making them an invaluable asset in any steel processing line. Industries that integrate these technologies into their production processes attest to the improved performance and reliability of their products, which not only meets but often exceeds international quality standards.

Authoritativeness The temper rolling mill is not just a machine; it epitomizes the pinnacle of metallurgy and mechanical engineering expertise. Many industrial bodies and academic institutions have conducted extensive research on how temper rolling affects metal properties. Studies have illustrated that temper rolling can significantly improve flatness and surface texture, which are critical for applications requiring tight aesthetic and functional specifications. The mill’s capability to enhance anti-corrosive properties by refining the grain structure of the metal is widely documented in metallurgical journals. Additionally, industry experts regularly confer about the optimum settings for various metals to achieve desired outcomes. This ongoing dialogue among professionals is testament to the authority that temper rolling mills command in the industry. Manufacturers of temper rolling mills continue to innovate, frequently enhancing their equipment's capabilities, thus solidifying their standing as leaders in metal processing solutions. Trustworthiness The reputation of temper rolling mills is supported by a robust foundation of trust built over decades of consistent performance in metal refining. Customers from industries such as automotive, aerospace, and construction rely heavily on the quality assurance that these mills provide. When precision and reliability are paramount, the temper rolling mill becomes the trusted choice. Companies often showcase certifications and compliance with international steel quality standards as testament to the trustworthiness of their products processed through temper rolling techniques. Furthermore, the manufacturers of these mills offer comprehensive support and maintenance services, ensuring that their machines operate at peak efficiency and reliability. Many companies also provide training programs to ensure that operators are well-versed in the operation and maintenance of the machinery, which in turn reinforces the trust in the product’s reliability. In conclusion, temper rolling mills stand out in the metalworking sector for their ability to enhance product quality while maintaining dimensional precision. Their role is undisputed among professionals who demand the highest standards in their metal products, making them an invaluable asset in any steel processing line. Industries that integrate these technologies into their production processes attest to the improved performance and reliability of their products, which not only meets but often exceeds international quality standards.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products