работа дрессировочного стана

مارس . 06, 2025 13:15

Back to list

работа дрессировочного стана

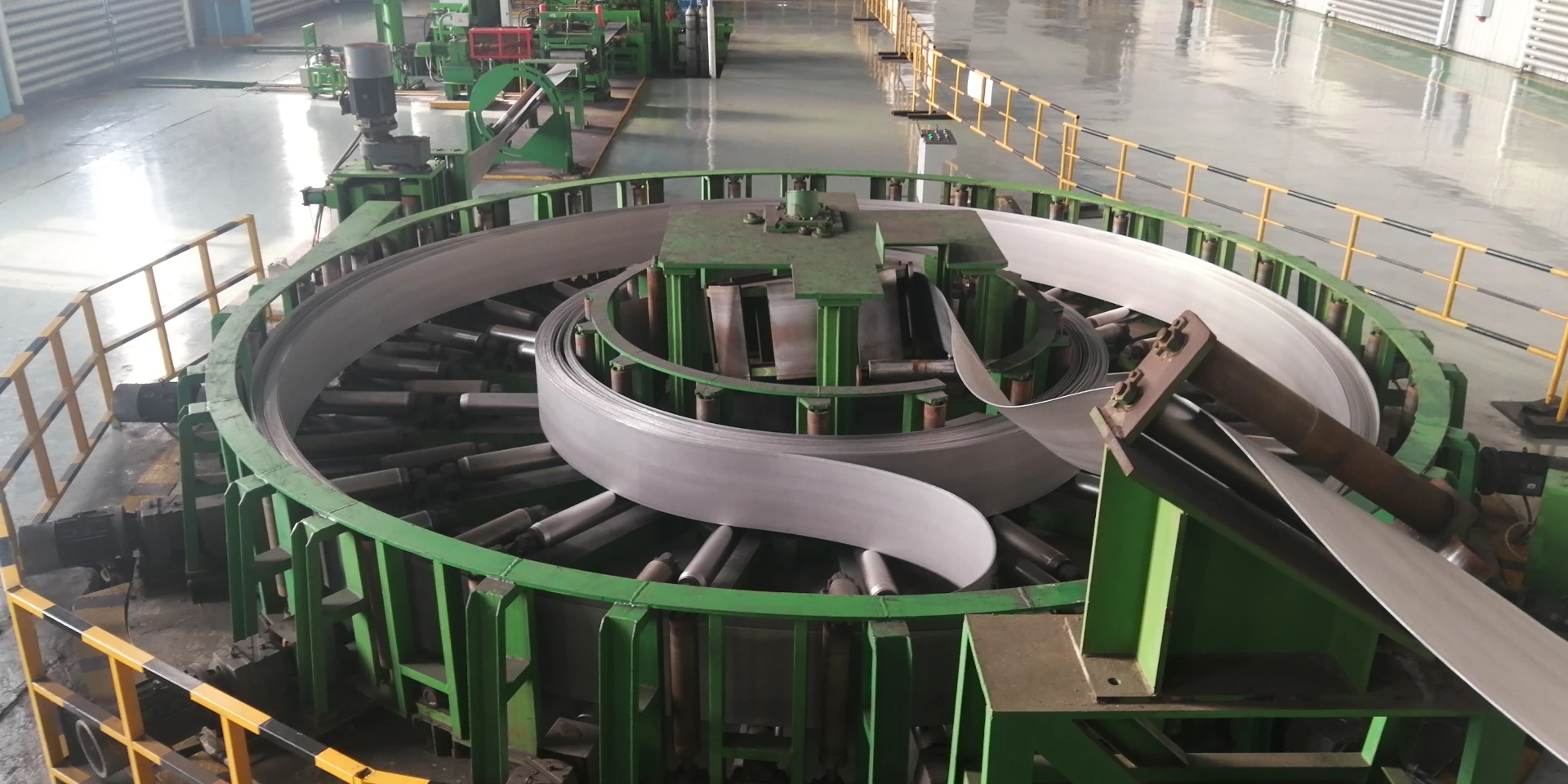

The modern realm of industrial manufacturing places immense importance on the efficiency and maintenance of powerful equipment like the dressing mill. Regarded as a pivotal component in production lines, this machine demands not only technical know-how but also a seasoned understanding of its operational workflows. Our interactions with multiple industry stalwarts have unveiled some insightful experiences and expert evaluations that can guide both beginners and seasoned professionals towards maximizing productivity and machine longevity.

However, even the most advanced machinery and software can fall short without proper safety protocols in place. Safety, as emphasized by industry leaders, ensures not only the well-being of personnel but also the integrity of the equipment. Companies that prioritize safety training and adhere to stringent safety guidelines often see a corresponding increase in productivity. This is because operators who feel secure are more likely to function at peak efficiency, knowing that the machinery they operate is maintained with their welfare in mind. Furthermore, the trustworthiness of a dressing mill's performance is often linked to the quality of its components. Purchasing components from reputable suppliers and collaborating with respected manufacturers translates to enhanced reliability and efficiency. Industry experts recommend establishing a robust procurement strategy that factors in cost, quality, and supplier credibility. This strategic emphasis has consistently demonstrated better operational outcomes in terms of machine reliability and production throughput. In conclusion, mastering the operations of a dressing mill is a complex yet rewarding endeavor that blends practical experience with theoretical knowledge. Capturing insights from industry veterans and adhering to a holistic approach that includes regular maintenance, effective training, safety adherence, and strategic procurement, companies can not only achieve higher productivity but also secure their investment in expensive industrial equipment. As manufacturing continues to grow more sophisticated, the role of the dressing mill remains critical, underscoring the necessity for continuous learning and adaptation. This continuous evolution, supported by shared expertise and industry collaboration, ensures that the dressing mill remains an indispensable pillar in the realm of efficient production.

However, even the most advanced machinery and software can fall short without proper safety protocols in place. Safety, as emphasized by industry leaders, ensures not only the well-being of personnel but also the integrity of the equipment. Companies that prioritize safety training and adhere to stringent safety guidelines often see a corresponding increase in productivity. This is because operators who feel secure are more likely to function at peak efficiency, knowing that the machinery they operate is maintained with their welfare in mind. Furthermore, the trustworthiness of a dressing mill's performance is often linked to the quality of its components. Purchasing components from reputable suppliers and collaborating with respected manufacturers translates to enhanced reliability and efficiency. Industry experts recommend establishing a robust procurement strategy that factors in cost, quality, and supplier credibility. This strategic emphasis has consistently demonstrated better operational outcomes in terms of machine reliability and production throughput. In conclusion, mastering the operations of a dressing mill is a complex yet rewarding endeavor that blends practical experience with theoretical knowledge. Capturing insights from industry veterans and adhering to a holistic approach that includes regular maintenance, effective training, safety adherence, and strategic procurement, companies can not only achieve higher productivity but also secure their investment in expensive industrial equipment. As manufacturing continues to grow more sophisticated, the role of the dressing mill remains critical, underscoring the necessity for continuous learning and adaptation. This continuous evolution, supported by shared expertise and industry collaboration, ensures that the dressing mill remains an indispensable pillar in the realm of efficient production.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products