Agc System For Hot/Cold Strip Rolling Mill

Feb . 18, 2025 12:42

Back to list

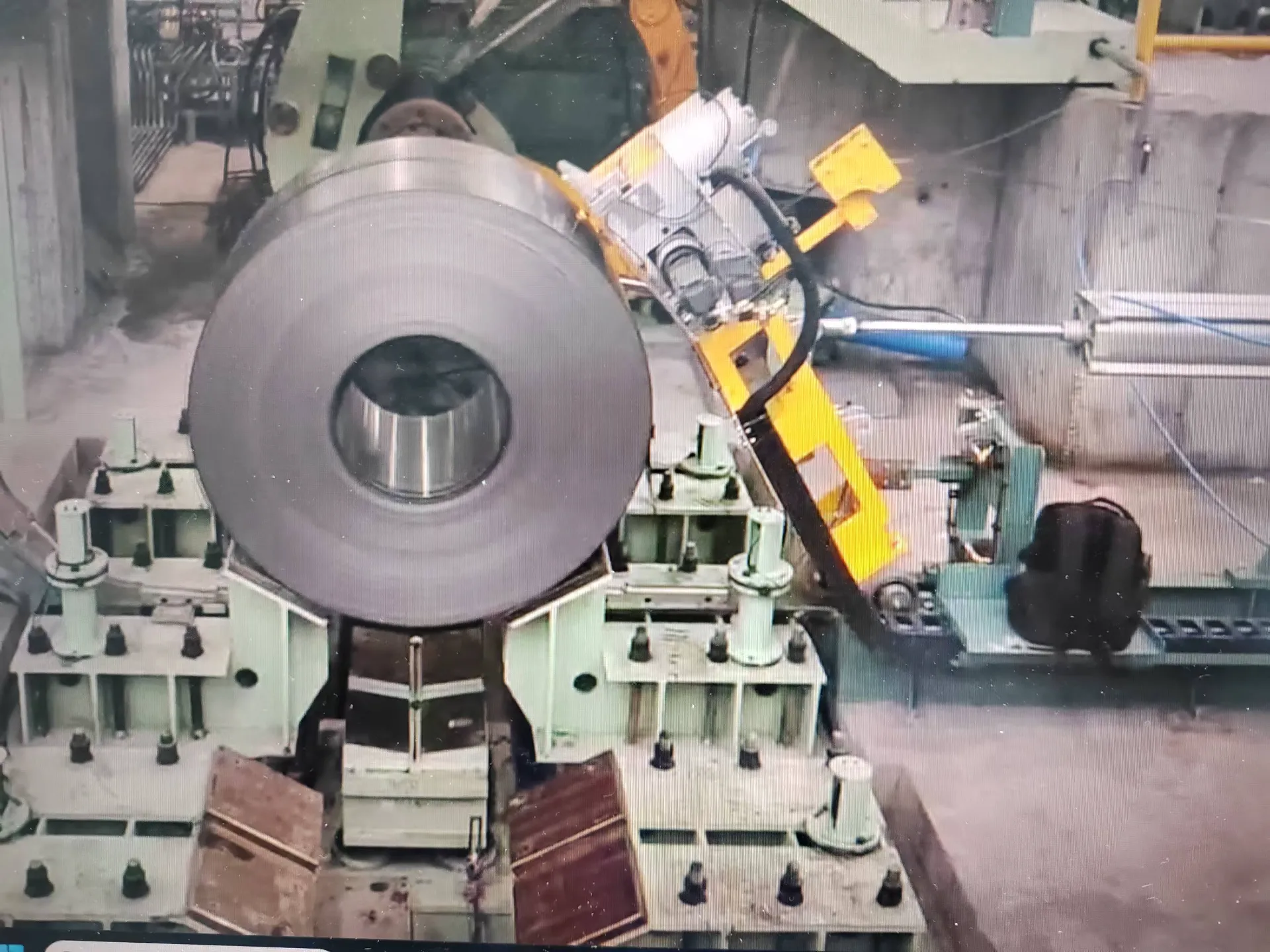

Agc System For Hot/Cold Strip Rolling Mill

Understanding the nuances of industrial machinery can be daunting, but it’s paramount for professionals seeking efficiency in manufacturing processes. One such term is the Skin Pass Mill or in question-form What is a skin pass mill? This article will demystify this integral component of metal production, underlining its functionalities, benefits, and applications in industrial settings.

The consistency in product quality attributed to the skin pass mill is a direct result of high-precision control systems that regulate thickness and surface treatment. Many experts in the metallurgy field argue that the inclusion of a skin pass mill can significantly enhance manufacturing profitability by reducing the need for downstream processing corrections. With regard to authoritativeness, companies utilizing skin pass mills often gain an edge in industries where material quality cannot be compromised. An esteemed organization that frequently employs skin pass mills is ArcelorMittal, the world’s leading steel and mining company. Their extensive use of advanced skin pass technology underscores its importance in achieving high-caliber outcomes conforming to international standards. Trustworthiness in using skin pass milling arises from its established track record in alleviating defects and improving the end product's consistency. Equipment manufacturers and users who have integrated skin passing practices regularly report reductions in product rejection rates and customer complaints due to improved sheet metal properties. In conclusion, for those dealing with metal production, particularly in sectors where high quality and surface precision are non-negotiable, investing in a skin pass mill is not merely beneficial but vital. It exemplifies a perfect blend of technological advancement and practical application, making it an unrivaled asset in the sphere of metallurgy and industrial manufacturing. Integrating it into production lines promises not only superior product attributes but also augmented profit margins, reinforcing its indispensable role in the industry.

The consistency in product quality attributed to the skin pass mill is a direct result of high-precision control systems that regulate thickness and surface treatment. Many experts in the metallurgy field argue that the inclusion of a skin pass mill can significantly enhance manufacturing profitability by reducing the need for downstream processing corrections. With regard to authoritativeness, companies utilizing skin pass mills often gain an edge in industries where material quality cannot be compromised. An esteemed organization that frequently employs skin pass mills is ArcelorMittal, the world’s leading steel and mining company. Their extensive use of advanced skin pass technology underscores its importance in achieving high-caliber outcomes conforming to international standards. Trustworthiness in using skin pass milling arises from its established track record in alleviating defects and improving the end product's consistency. Equipment manufacturers and users who have integrated skin passing practices regularly report reductions in product rejection rates and customer complaints due to improved sheet metal properties. In conclusion, for those dealing with metal production, particularly in sectors where high quality and surface precision are non-negotiable, investing in a skin pass mill is not merely beneficial but vital. It exemplifies a perfect blend of technological advancement and practical application, making it an unrivaled asset in the sphere of metallurgy and industrial manufacturing. Integrating it into production lines promises not only superior product attributes but also augmented profit margins, reinforcing its indispensable role in the industry.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products