کنترل کشش حلقه بسته

Feb . 15, 2025 09:37

Back to list

کنترل کشش حلقه بسته

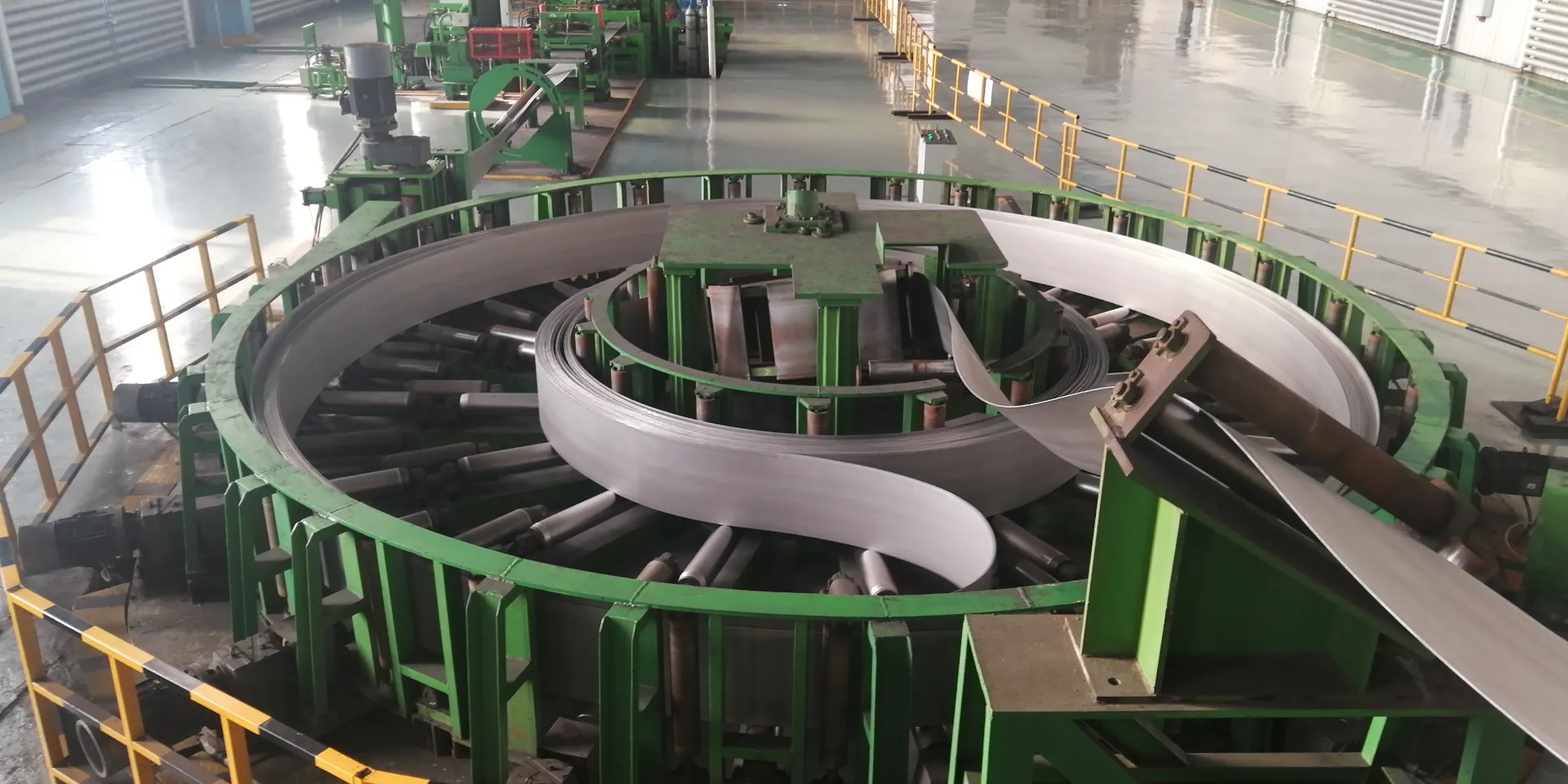

Closed-loop tension control is a critical component in modern industrial processes, particularly within the realms of manufacturing and product quality. The technology ensures that tension in materials, such as webs of paper, metal strips, or plastic films, is maintained consistently through various stages of production. This precision is often essential in industries like printing, packaging, textiles, and electronics, where material properties can significantly affect final product quality.

The authoritative voice in this domain often comes from academic research backed by practical applications. Studies have demonstrated how closed-loop tension control can extend beyond traditional uses to enhance processes in emerging industries, such as flexible electronics or biofilm production. For instance, maintaining precise tension is critical in the deposition of conductive materials onto flexible substrates in electronics manufacturing. These advanced uses illustrate how closed-loop systems are central to innovative manufacturing techniques, demonstrating the authoritative role these systems play in modern production lines. Trustworthiness in the context of closed-loop tension control systems is demonstrated through reliability and repeatability in real-world applications. Systems are often subjected to rigorous testing, following international standards to ensure they perform effectively under various conditions. For example, the International Electrotechnical Commission (IEC) standards provide comprehensive guidelines for evaluating the performance of tension control systems, ensuring they meet necessary safety and operational criteria. Proven compliance with such standards helps build trust among end-users and industry stakeholders. A successful closed-loop tension control system implementation draws on a deep understanding of both theoretical principles and practical engineering solutions. Companies specializing in these systems often offer consultation services to tailor solutions to specific production needs, thereby enhancing operational efficacy. They will conduct a comprehensive analysis of the client's production process, identifying areas where tension control can be optimized to maximize production efficiency and product quality. Overall, closed-loop tension control embodies the integration of cutting-edge technology with industrial application, ensuring quality and efficiency in production processes across various industries. It's a field that not only requires technical expertise and innovation but also a robust foundation of authoritative standards and trustworthy practices, serving as a linchpin for achieving high manufacturing standards in today’s competitive market landscape.

The authoritative voice in this domain often comes from academic research backed by practical applications. Studies have demonstrated how closed-loop tension control can extend beyond traditional uses to enhance processes in emerging industries, such as flexible electronics or biofilm production. For instance, maintaining precise tension is critical in the deposition of conductive materials onto flexible substrates in electronics manufacturing. These advanced uses illustrate how closed-loop systems are central to innovative manufacturing techniques, demonstrating the authoritative role these systems play in modern production lines. Trustworthiness in the context of closed-loop tension control systems is demonstrated through reliability and repeatability in real-world applications. Systems are often subjected to rigorous testing, following international standards to ensure they perform effectively under various conditions. For example, the International Electrotechnical Commission (IEC) standards provide comprehensive guidelines for evaluating the performance of tension control systems, ensuring they meet necessary safety and operational criteria. Proven compliance with such standards helps build trust among end-users and industry stakeholders. A successful closed-loop tension control system implementation draws on a deep understanding of both theoretical principles and practical engineering solutions. Companies specializing in these systems often offer consultation services to tailor solutions to specific production needs, thereby enhancing operational efficacy. They will conduct a comprehensive analysis of the client's production process, identifying areas where tension control can be optimized to maximize production efficiency and product quality. Overall, closed-loop tension control embodies the integration of cutting-edge technology with industrial application, ensuring quality and efficiency in production processes across various industries. It's a field that not only requires technical expertise and innovation but also a robust foundation of authoritative standards and trustworthy practices, serving as a linchpin for achieving high manufacturing standards in today’s competitive market landscape.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products