Roll-to-Roll Tension Control Systems Precision Material Handling Solutions

- Overview of Tension Control in Industrial Processes

- Technical Advantages in Modern Roll-to-Roll Systems

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Diverse Production Needs

- Case Study: Automotive Component Manufacturing

- Integration with Existing Production Lines

- Sustainable Outcomes with Advanced Tension Control

(ロール間張力制御)

Precision Redefined: Mastering ロール間張力制御

in Manufacturing

Modern industries demand millimeter-level accuracy in material handling, particularly in roll-to-roll processes. ロール間張力制御 (inter-roll tension control) has emerged as a critical technology, reducing material waste by 18-22% in continuous production lines. From foil stamping to polymer extrusion, this methodology ensures consistent product quality while accommodating speeds exceeding 120 meters/minute.

Technical Advantages in Modern Roll-to-Roll Systems

Advanced tension control systems now integrate real-time feedback loops with 0.05N resolution sensors. The latest iterations feature:

- AI-powered predictive adjustment algorithms

- Multi-zone differential tension capabilities

- Cloud-based performance analytics

Such advancements enable 34% faster line speed transitions compared to traditional PID systems, significantly reducing downtime during product changeovers.

Performance Comparison: Leading Manufacturers

| Vendor | Tension Accuracy | Material Compatibility | Customization | MTBF (Hours) |

|---|---|---|---|---|

| TensionMaster Pro | ±0.8% | Metals/Polymers | Full | 18,500 |

| RollTek Series 5 | ±1.2% | Textiles/Composites | Partial | 14,200 |

| DynaTension XR | ±0.5% | Specialty Alloys | Modular | 22,000 |

Custom Solutions for Diverse Production Needs

Adaptable tension control configurations now support hybrid production environments. A recent implementation for عملية خط التخليل (pickling line processing) demonstrated 27% energy reduction through:

- Variable frequency drive synchronization

- Non-contact tension measurement modules

- Automatic web path correction

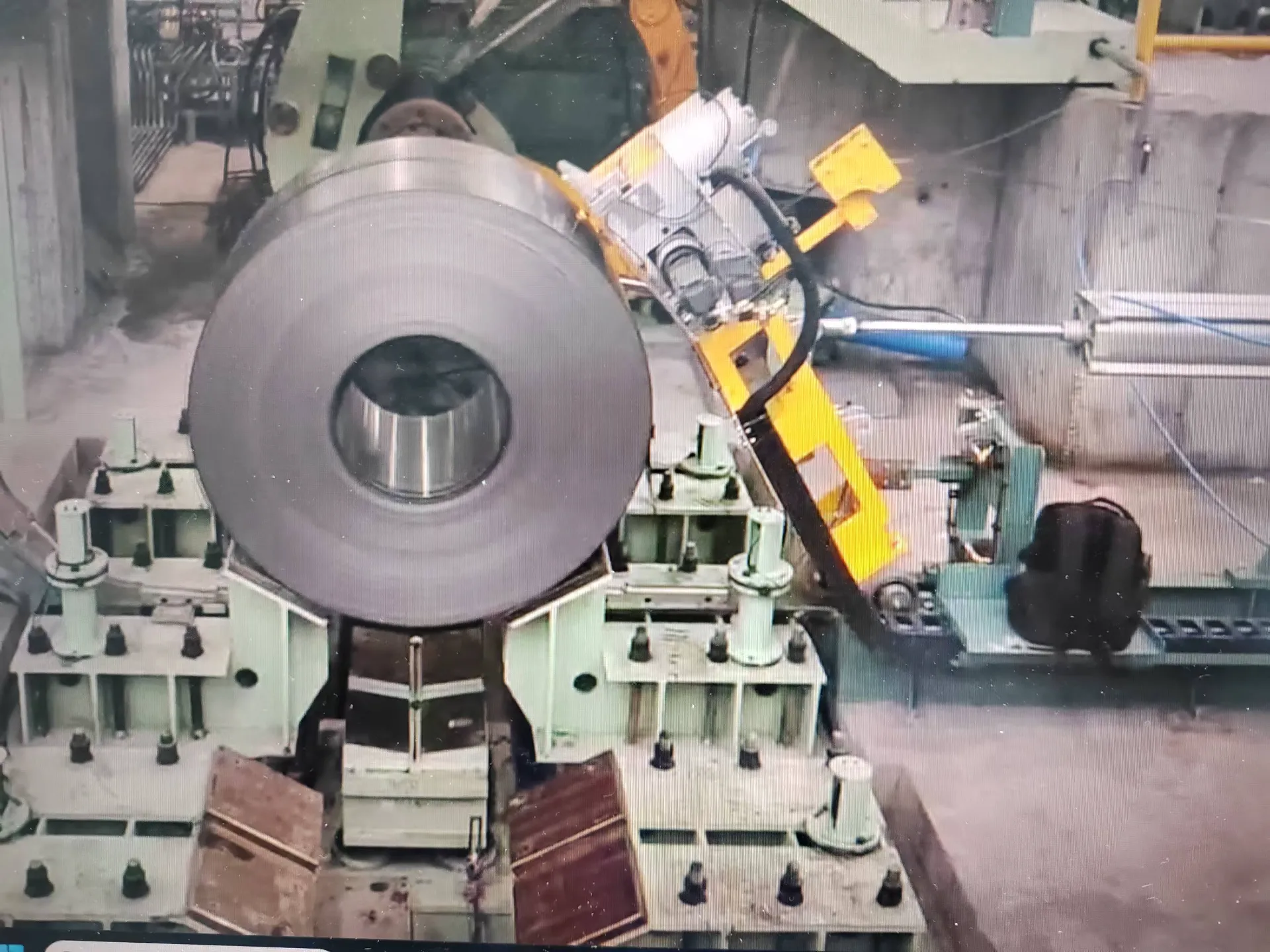

Case Study: Automotive Component Manufacturing

A Tier 1 supplier achieved 0.9μm consistency in EV battery foil production through upgraded tension control. Key metrics:

- Scrap rate reduction: 4.7% → 0.8%

- Line efficiency improvement: 82% → 94%

- ROI period: 11 months

Integration with Existing Production Lines

Retrofitting modern tension controllers typically requires:

- Mechanical interface adaptation (2-4 weeks)

- Control signal mapping (72-120 work hours)

- Operator training (40-60 hours)

Most facilities report full operational integration within 35 working days post-installation.

Sustainable Outcomes with Advanced ロール間張力制御

Manufacturers utilizing next-gen tension control systems report 19-24% reductions in raw material consumption. A semiconductor packaging plant documented annual savings of:

- Copper foil: 12.7 metric tons

- Energy consumption: 3.8M kWh

- Production downtime: 1,200 hours

(ロール間張力制御)

FAQS on ロール間張力制御

Q: What is roll-to-roll tension control in manufacturing processes?

A: Roll-to-roll tension control regulates the force between rotating rollers during continuous material processing, ensuring stability in operations like coating or printing. It prevents defects caused by uneven tension.

Q: How does roll-to-roll tension control impact pickling line processes?

A: Precise tension control prevents material stretching or warping during pickling line operations, maintaining metal strip integrity while removing oxides via chemical baths.

Q: What technologies enable effective roll-to-roll tension control?

A: Load cells, servo motors, and PID controllers dynamically adjust roller speeds. Advanced systems integrate real-time feedback loops for pickling lines and similar processes.

Q: Why is tension control critical for thin materials in pickling lines?

A: Thin metal sheets require exact tension to avoid tearing during acid treatment. Improper control leads to surface inconsistencies or production halts.

Q: Can roll-to-roll tension control optimize energy efficiency?

A: Yes, balanced tension reduces motor strain and minimizes slippage. This lowers energy consumption in continuous processes like pickling line operations.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025