winding tension control

Feb . 14, 2025 10:43

Back to list

winding tension control

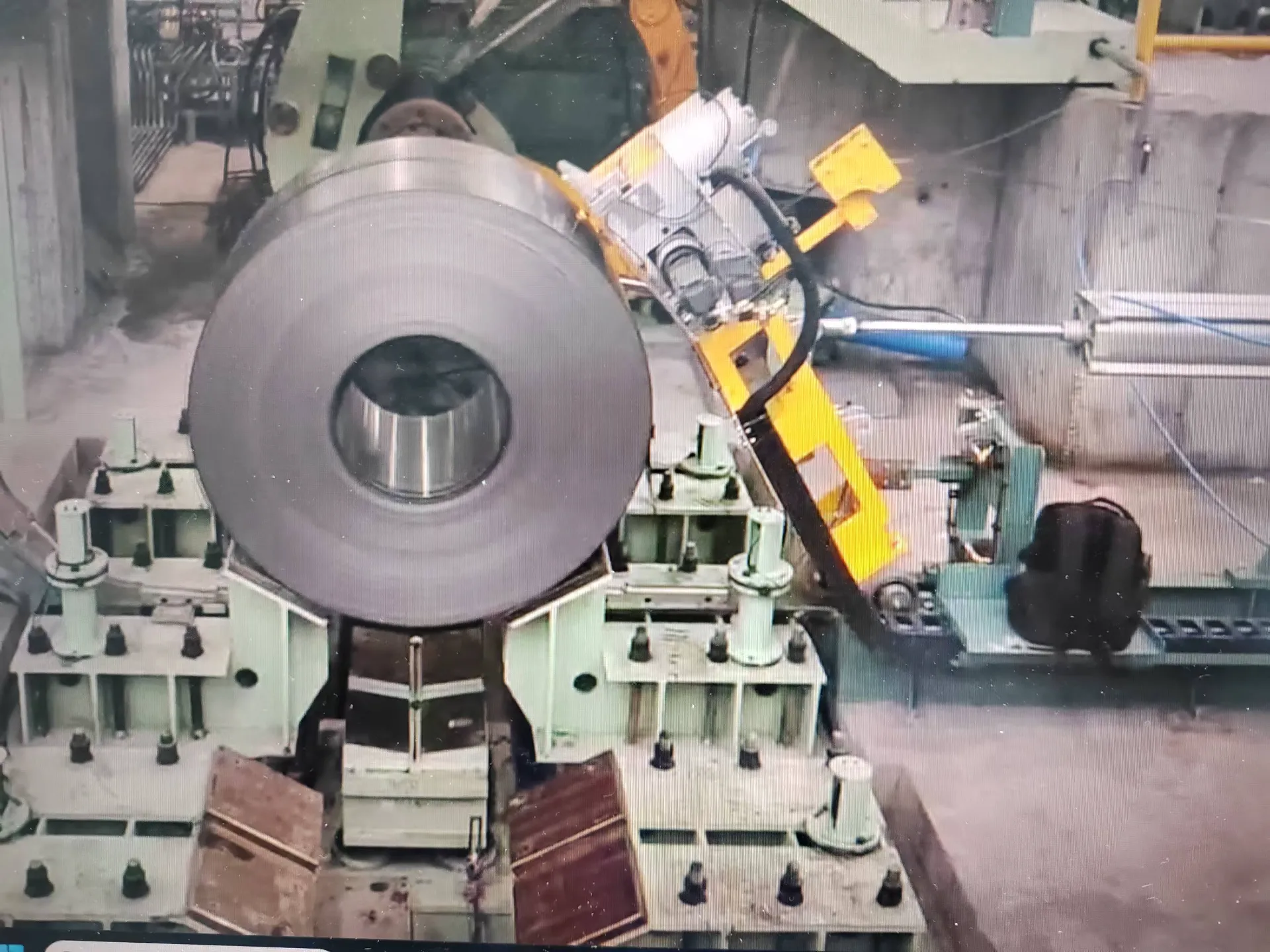

Winding tension control plays a pivotal role in numerous industrial applications, ensuring that materials like fabrics, wires, or films are wound correctly without causing breakages or inconsistencies. Companies aiming to optimize their manufacturing process must invest in understanding and implementing effective winding tension control methods. Real-world insights from industries reveal that precise tension control substantially enhances product quality while minimizing waste and costly downtimes.

Trustworthiness in winding tension control systems is non-negotiable, especially in processes involving delicate or high-value materials. Companies seeking reputable solutions often collaborate with manufacturers who have a proven track record of innovation and reliability. Implementing tension control systems from trusted providers assures manufacturers of system longevity and performance consistency. Moreover, these systems often come with comprehensive post-sale support, ensuring that any potential issues are swiftly and effectively addressed, bolstering a company's operational trustworthiness. Authoritativeness in winding tension control is achieved through continuous research and development. Leading corporations invest heavily in R&D to push the boundaries of existing technology. For example, integrating IoT technology with tension control systems enables greater oversight and precision. Manufacturers leverage real-time data analytics to predict and prevent tension-related anomalies, ensuring uninterrupted production and higher yield rates. This cutting-edge approach not only demonstrates authority in technological advancement but also economically benefits businesses by reducing downtime and increasing production capacity. Lastly, authenticity in experience is critical for enterprises striving for excellence in winding tension control. Firms that prioritize training and development of their workforce in tension control technology often outperform their competitors. By equipping their teams with the necessary skills and understanding of the latest technologies, companies ensure that they remain at the forefront of the industry, delivering unparalleled product quality and efficiency. In conclusion, winding tension control is intrinsically linked to the success of many manufacturing processes. Whether it's in textiles, cable production, or film manufacturing, exemplary tension control reflects an organization’s commitment to quality, efficiency, and customer satisfaction. Companies striving for excellence must therefore not only adopt advanced tension control systems but also invest in ongoing professional development and cutting-edge research to maintain their competitive edge in the market.

Trustworthiness in winding tension control systems is non-negotiable, especially in processes involving delicate or high-value materials. Companies seeking reputable solutions often collaborate with manufacturers who have a proven track record of innovation and reliability. Implementing tension control systems from trusted providers assures manufacturers of system longevity and performance consistency. Moreover, these systems often come with comprehensive post-sale support, ensuring that any potential issues are swiftly and effectively addressed, bolstering a company's operational trustworthiness. Authoritativeness in winding tension control is achieved through continuous research and development. Leading corporations invest heavily in R&D to push the boundaries of existing technology. For example, integrating IoT technology with tension control systems enables greater oversight and precision. Manufacturers leverage real-time data analytics to predict and prevent tension-related anomalies, ensuring uninterrupted production and higher yield rates. This cutting-edge approach not only demonstrates authority in technological advancement but also economically benefits businesses by reducing downtime and increasing production capacity. Lastly, authenticity in experience is critical for enterprises striving for excellence in winding tension control. Firms that prioritize training and development of their workforce in tension control technology often outperform their competitors. By equipping their teams with the necessary skills and understanding of the latest technologies, companies ensure that they remain at the forefront of the industry, delivering unparalleled product quality and efficiency. In conclusion, winding tension control is intrinsically linked to the success of many manufacturing processes. Whether it's in textiles, cable production, or film manufacturing, exemplary tension control reflects an organization’s commitment to quality, efficiency, and customer satisfaction. Companies striving for excellence must therefore not only adopt advanced tension control systems but also invest in ongoing professional development and cutting-edge research to maintain their competitive edge in the market.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products