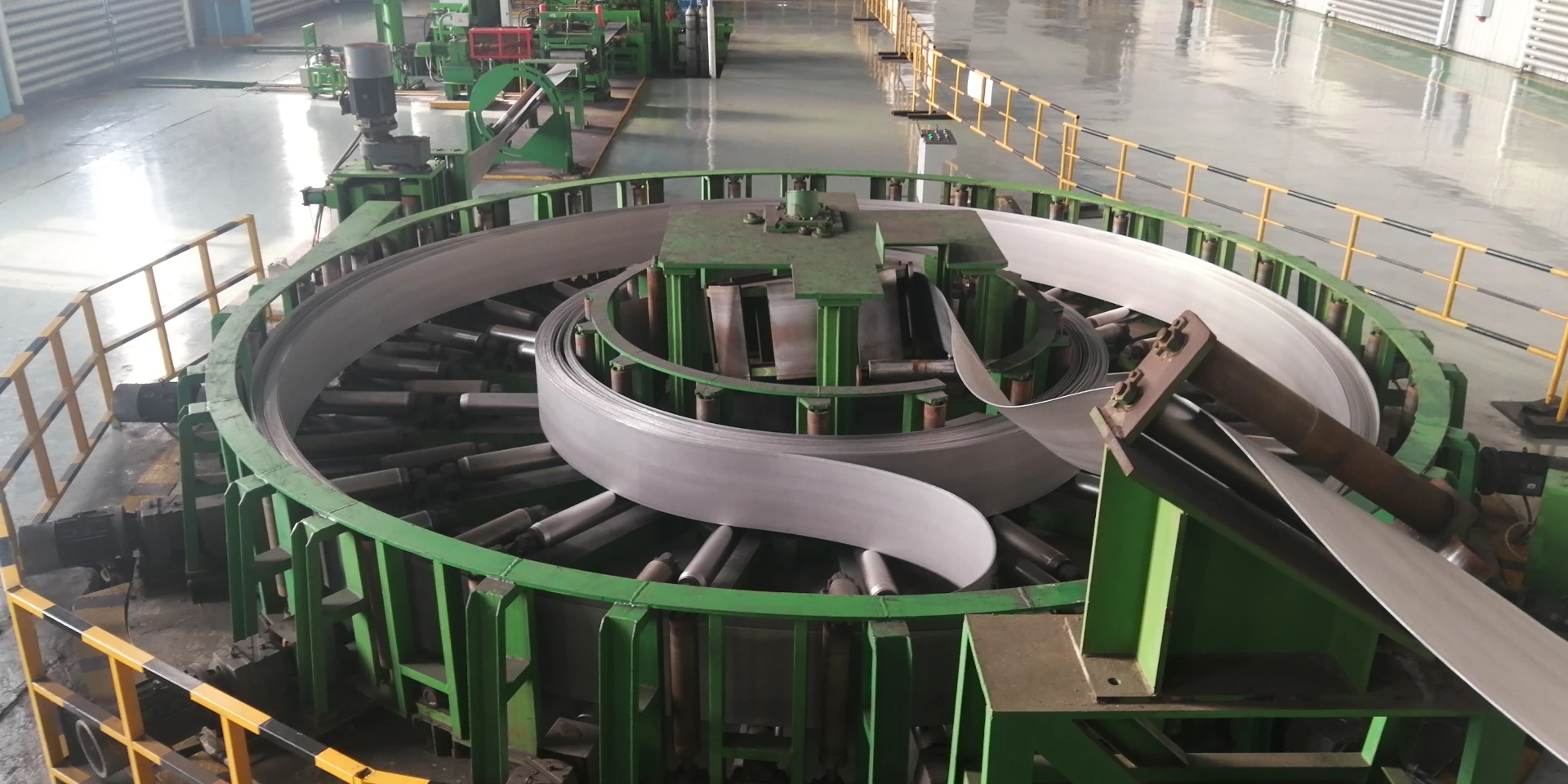

roll bonding cladding

Jan . 19, 2025 03:42

Back to list

roll bonding cladding

Transverse cracks represent a significant challenge in various industries, from construction to automotive. Understanding the intricacies of these cracks is vital for professionals who aim to address or prevent them in their products. With years of hands-on experience, combined with a profound understanding of the materials and environments that lead to such cracks, we explore how to tackle this prevalent issue with authority and trust.

Inspection and maintenance also play a pivotal role in cracking management. Implementing regular maintenance routines using advanced imaging technologies, such as infrared thermography or ultrasonic testing, enables early crack detection. By addressing these micro-level flaws before they propagate into significant faults, industries can preempt costly repairs and ensure product longevity. Furthermore, developing predictive models using AI and machine learning allows industries to anticipate crack formation conditions. These technologies analyze historical data patterns, identifying trends that would otherwise go unnoticed by human observation alone. By integrating these insights into their preventive strategies, companies gain a competitive edge through proactive maintenance. Given the myriad of approaches to tackle transverse cracks, assembling a multidisciplinary team ensures comprehensive solutions. Collaborating with material scientists, engineers, and field technicians offers holistic insights into product development phases, from material selection to final testing. For product managers and quality assurance experts, this collaboration bridges the gap between theoretical knowledge and practical applications, enhancing the reliability and credibility of their products. In the pursuit of authoritative knowledge and solutions concerning transverse cracks, continuous research and development are indispensable. Sharing case studies and field results in professional circles fosters knowledge exchange and innovation, encouraging industry-wide advancements in material sciences and cracking prevention. Effective communication regarding strategies to combat transverse cracks also establishes trust within industry circles and consumer bases. Providing transparent, easily digestible information about preventive measures reassures stakeholders of the product's integrity and the company's commitment to excellence. In conclusion, addressing transverse cracks requires a multifaceted approach that spans selection of appropriate materials, design considerations, and regular maintenance. Industries that integrate experience, expertise, and innovative technology solutions in their strategies not only curb the formation of transverse cracks but also bolster the durability and confidence in their products.

Inspection and maintenance also play a pivotal role in cracking management. Implementing regular maintenance routines using advanced imaging technologies, such as infrared thermography or ultrasonic testing, enables early crack detection. By addressing these micro-level flaws before they propagate into significant faults, industries can preempt costly repairs and ensure product longevity. Furthermore, developing predictive models using AI and machine learning allows industries to anticipate crack formation conditions. These technologies analyze historical data patterns, identifying trends that would otherwise go unnoticed by human observation alone. By integrating these insights into their preventive strategies, companies gain a competitive edge through proactive maintenance. Given the myriad of approaches to tackle transverse cracks, assembling a multidisciplinary team ensures comprehensive solutions. Collaborating with material scientists, engineers, and field technicians offers holistic insights into product development phases, from material selection to final testing. For product managers and quality assurance experts, this collaboration bridges the gap between theoretical knowledge and practical applications, enhancing the reliability and credibility of their products. In the pursuit of authoritative knowledge and solutions concerning transverse cracks, continuous research and development are indispensable. Sharing case studies and field results in professional circles fosters knowledge exchange and innovation, encouraging industry-wide advancements in material sciences and cracking prevention. Effective communication regarding strategies to combat transverse cracks also establishes trust within industry circles and consumer bases. Providing transparent, easily digestible information about preventive measures reassures stakeholders of the product's integrity and the company's commitment to excellence. In conclusion, addressing transverse cracks requires a multifaceted approach that spans selection of appropriate materials, design considerations, and regular maintenance. Industries that integrate experience, expertise, and innovative technology solutions in their strategies not only curb the formation of transverse cracks but also bolster the durability and confidence in their products.

Latest news

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

-

The Pivotal Position of Hot Rolling Mills in the Iron and Steel Industry ChainNewsMay.13,2025

Related Products