tension control clutch

Feb . 14, 2025 07:02

Back to list

tension control clutch

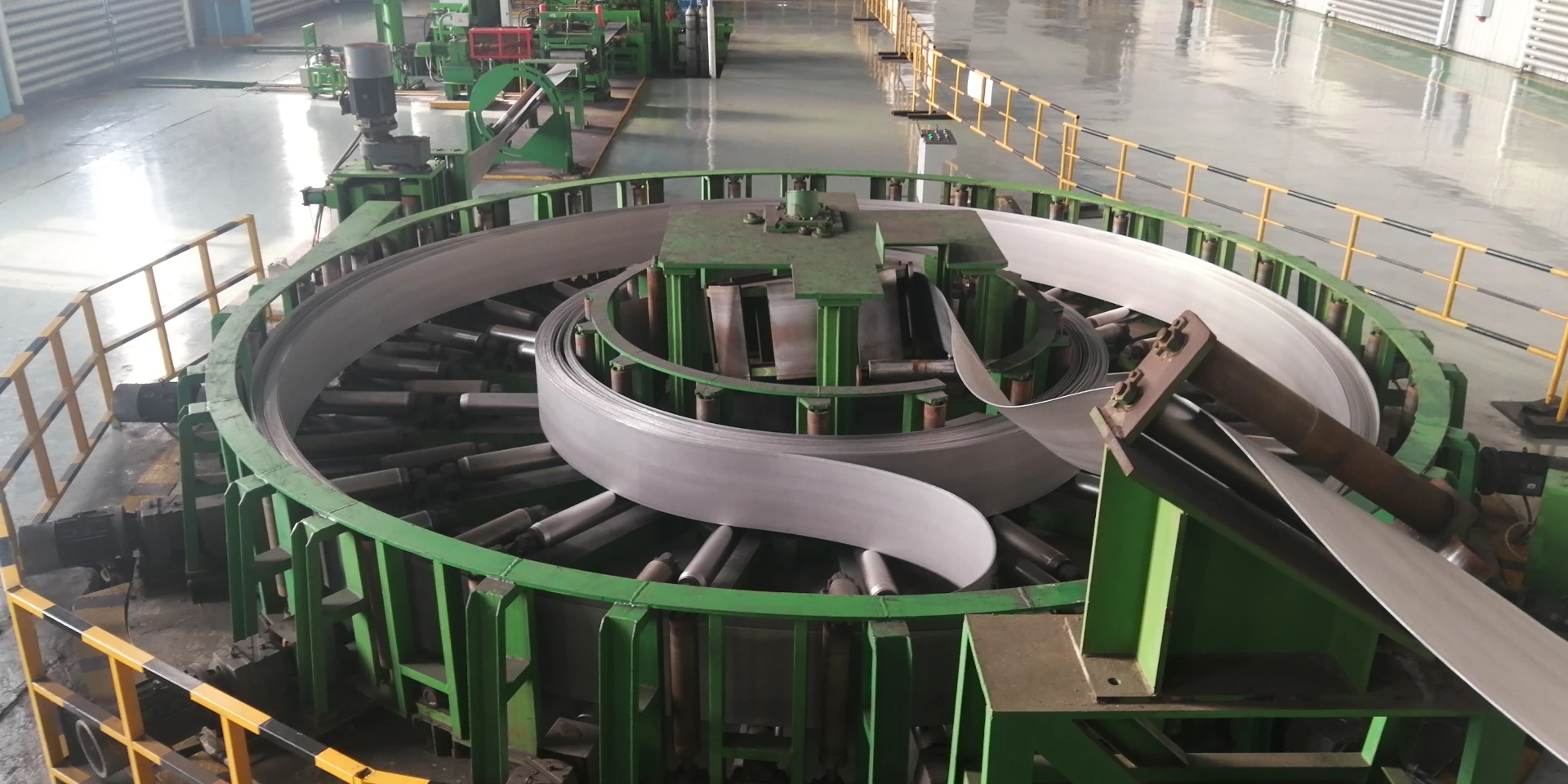

Tension control clutches are pivotal in numerous industrial applications, offering precise control and management of tension in various systems. Their significance stems not only from their functional utility but also from their contribution to operational efficiency and product quality, especially in the manufacturing and processing industries.

The textiles industry also relies heavily on the precision that tension control clutches bring. Managing the intricate details of fabric tension during various stages of textile production ensures uniformity and consistency, which is critical in maintaining the desired fabric quality. Professionals in the textiles sector understand the complexities of working with different fabric types, and the expertise required to adjust tension settings accordingly highlights the specialized knowledge embedded within these tension control systems. For new market entrants aiming to distinguish their products from competitors, investing in tension control technology represents smart business acumen. By aligning with manufacturers who display expertise and authoritative know-how in tension control clutches, businesses can develop reputations for reliability and excellence, fostering long-term customer relationships built on trust. In conclusion, tension control clutches are much more than mere mechanical components. They represent a sophisticated blend of engineering excellence and operational reliability that drives productivity and quality across various industries. Companies seeking to lead in their respective fields must prioritize the integration of innovative tension control solutions into their processes. This strategic approach will not only ensure superior product outcomes but also reinforce the organization's reputation as a trusted leader in quality and efficiency.

The textiles industry also relies heavily on the precision that tension control clutches bring. Managing the intricate details of fabric tension during various stages of textile production ensures uniformity and consistency, which is critical in maintaining the desired fabric quality. Professionals in the textiles sector understand the complexities of working with different fabric types, and the expertise required to adjust tension settings accordingly highlights the specialized knowledge embedded within these tension control systems. For new market entrants aiming to distinguish their products from competitors, investing in tension control technology represents smart business acumen. By aligning with manufacturers who display expertise and authoritative know-how in tension control clutches, businesses can develop reputations for reliability and excellence, fostering long-term customer relationships built on trust. In conclusion, tension control clutches are much more than mere mechanical components. They represent a sophisticated blend of engineering excellence and operational reliability that drives productivity and quality across various industries. Companies seeking to lead in their respective fields must prioritize the integration of innovative tension control solutions into their processes. This strategic approach will not only ensure superior product outcomes but also reinforce the organization's reputation as a trusted leader in quality and efficiency.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products