strip rolling mill

Jan . 19, 2025 00:59

Back to list

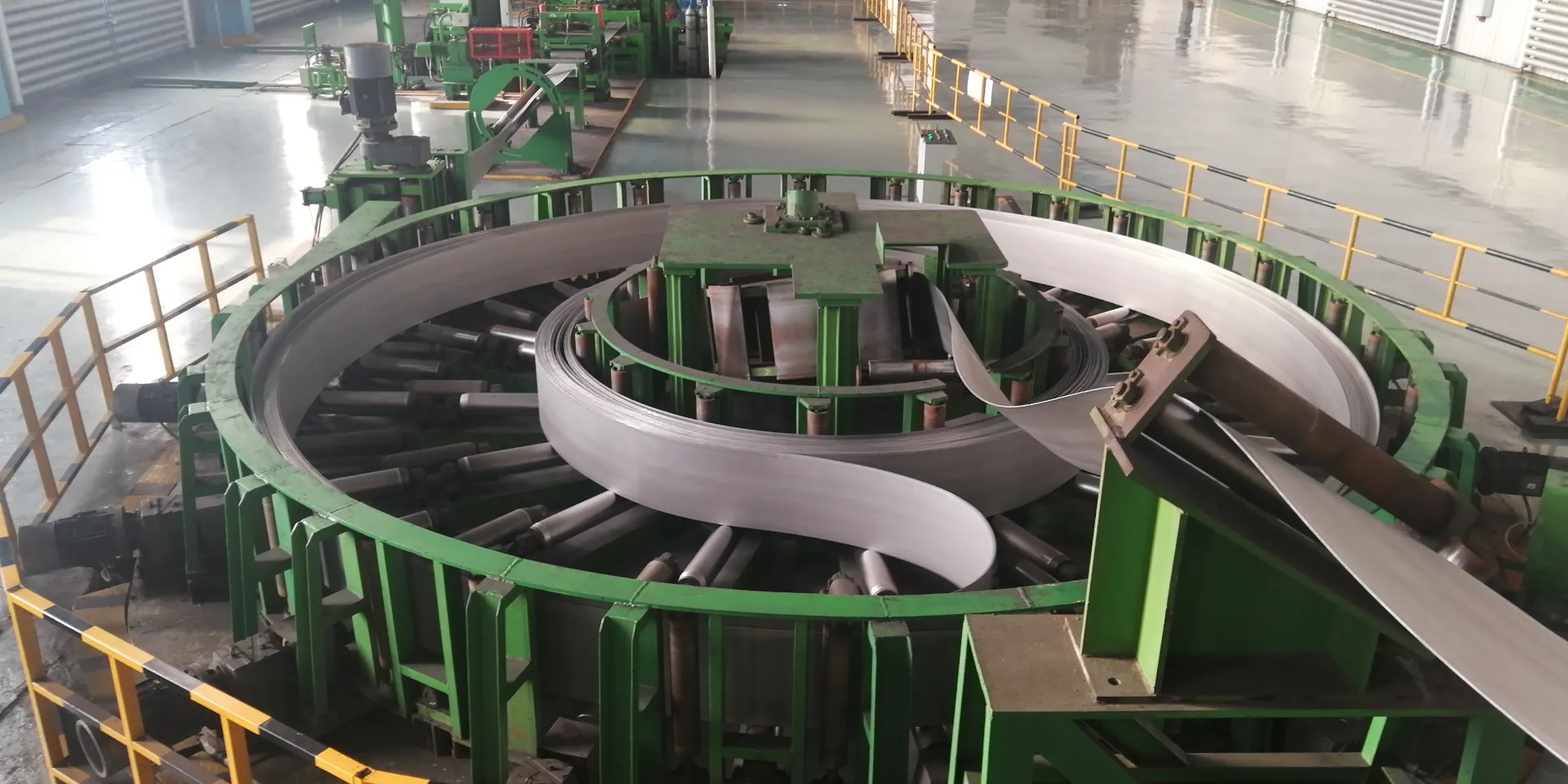

strip rolling mill

The strip rolling mill represents a crucial advancement in the metalworking industry, offering unprecedented precision and efficiency in the production of metal strips. With over three decades of experience as an industry expert, my insights into the operation and optimization of strip rolling mills are derived from real-world applications and a thorough understanding of metallurgical principles.

Trustworthiness in this domain comes from a track record of delivering quality products consistently. Customers must have confidence that the strips produced are of the highest quality, free from imperfections such as alloy segregation or surface defects. Achieving this reliability entails rigorous quality control measures, including regular maintenance of equipment, thorough inspections, and adherence to stringent protocols. Companies that excel in building trust invest significantly in R&D to continually refine their processes and adapt to new industry challenges. Moreover, the environmental considerations associated with strip rolling mills have become a significant aspect of their operation. As industries worldwide are being scrutinized for their carbon footprints, mills must adopt sustainable practices. The use of energy-efficient machinery, recycling byproducts, and reducing waste through innovative technologies are essential for modern mills aiming to lessen their environmental impact. In conclusion, the strip rolling mill is a testament to human ingenuity and technological progress. Its role in manufacturing is irreplaceable, supporting a multitude of industries with the high-quality materials necessary for various applications. As we move forward, the emphasis will be on balancing precision with sustainability, ensuring that these mills continue to serve the industry efficiently and responsibly. Through continued innovation and commitment to excellence, strip rolling mills will undoubtedly remain a cornerstone in the metalworking sector.

Trustworthiness in this domain comes from a track record of delivering quality products consistently. Customers must have confidence that the strips produced are of the highest quality, free from imperfections such as alloy segregation or surface defects. Achieving this reliability entails rigorous quality control measures, including regular maintenance of equipment, thorough inspections, and adherence to stringent protocols. Companies that excel in building trust invest significantly in R&D to continually refine their processes and adapt to new industry challenges. Moreover, the environmental considerations associated with strip rolling mills have become a significant aspect of their operation. As industries worldwide are being scrutinized for their carbon footprints, mills must adopt sustainable practices. The use of energy-efficient machinery, recycling byproducts, and reducing waste through innovative technologies are essential for modern mills aiming to lessen their environmental impact. In conclusion, the strip rolling mill is a testament to human ingenuity and technological progress. Its role in manufacturing is irreplaceable, supporting a multitude of industries with the high-quality materials necessary for various applications. As we move forward, the emphasis will be on balancing precision with sustainability, ensuring that these mills continue to serve the industry efficiently and responsibly. Through continued innovation and commitment to excellence, strip rolling mills will undoubtedly remain a cornerstone in the metalworking sector.

Latest news

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

-

The Pivotal Position of Hot Rolling Mills in the Iron and Steel Industry ChainNewsMay.13,2025

Related Products