Agc System For Hot/Cold Strip Rolling Mill

Feb . 16, 2025 02:43

Back to list

Agc System For Hot/Cold Strip Rolling Mill

The skin pass mill in galvanizing lines plays a crucial role in the production of high-quality galvanized steel, which is highly sought after across various industries for its durability and resistance to corrosion. The skin pass mill is often the unsung hero in the galvanizing process, ensuring the final product meets stringent quality standards. This article delves into the intricacies of the skin pass mill, exploring its role, benefits, and the technical expertise required to manage its operations effectively.

Trust in the finished product is paramount in industries relying on galvanized steel. A reliable skin pass mill process fosters this trust by eliminating potential defects and ensuring the end product adheres to international quality standards. This assurance builds confidence among manufacturers and end-users, encouraging wider adoption across sectors and geographies. Understanding the critical nature of the interactions within the skin pass mill allows for improvements in process efficiency and product quality. Technological advancements are continuously being integrated, like automated control systems that provide precise data monitoring and adjustments. These innovations minimize human error and align with modern manufacturing standards that demand high-speed production without compromising on quality. As environmental concerns loom large, the galvanizing industry, including skin pass mills, has been under pressure to reduce its ecological footprint. Innovations in mill technology now focus on energy efficiency and reduced emissions. Implementing eco-friendly practices, such as using recyclable materials in roll production and minimizing water usage during processing, supports the industry's shift towards sustainability. In conclusion, the skin pass mill galvanizing line is not merely a component but a pivotal player in the manufacturing of high-grade galvanized steel. It demands a blend of precision engineering, expert operation, and continual innovation to meet the evolving demands of quality and sustainability. As industries continue to value durability and performance, the importance of mastering the skin pass mill process will only grow, reinforcing its critical role in the steel manufacturing sector.

Trust in the finished product is paramount in industries relying on galvanized steel. A reliable skin pass mill process fosters this trust by eliminating potential defects and ensuring the end product adheres to international quality standards. This assurance builds confidence among manufacturers and end-users, encouraging wider adoption across sectors and geographies. Understanding the critical nature of the interactions within the skin pass mill allows for improvements in process efficiency and product quality. Technological advancements are continuously being integrated, like automated control systems that provide precise data monitoring and adjustments. These innovations minimize human error and align with modern manufacturing standards that demand high-speed production without compromising on quality. As environmental concerns loom large, the galvanizing industry, including skin pass mills, has been under pressure to reduce its ecological footprint. Innovations in mill technology now focus on energy efficiency and reduced emissions. Implementing eco-friendly practices, such as using recyclable materials in roll production and minimizing water usage during processing, supports the industry's shift towards sustainability. In conclusion, the skin pass mill galvanizing line is not merely a component but a pivotal player in the manufacturing of high-grade galvanized steel. It demands a blend of precision engineering, expert operation, and continual innovation to meet the evolving demands of quality and sustainability. As industries continue to value durability and performance, the importance of mastering the skin pass mill process will only grow, reinforcing its critical role in the steel manufacturing sector.

Latest news

-

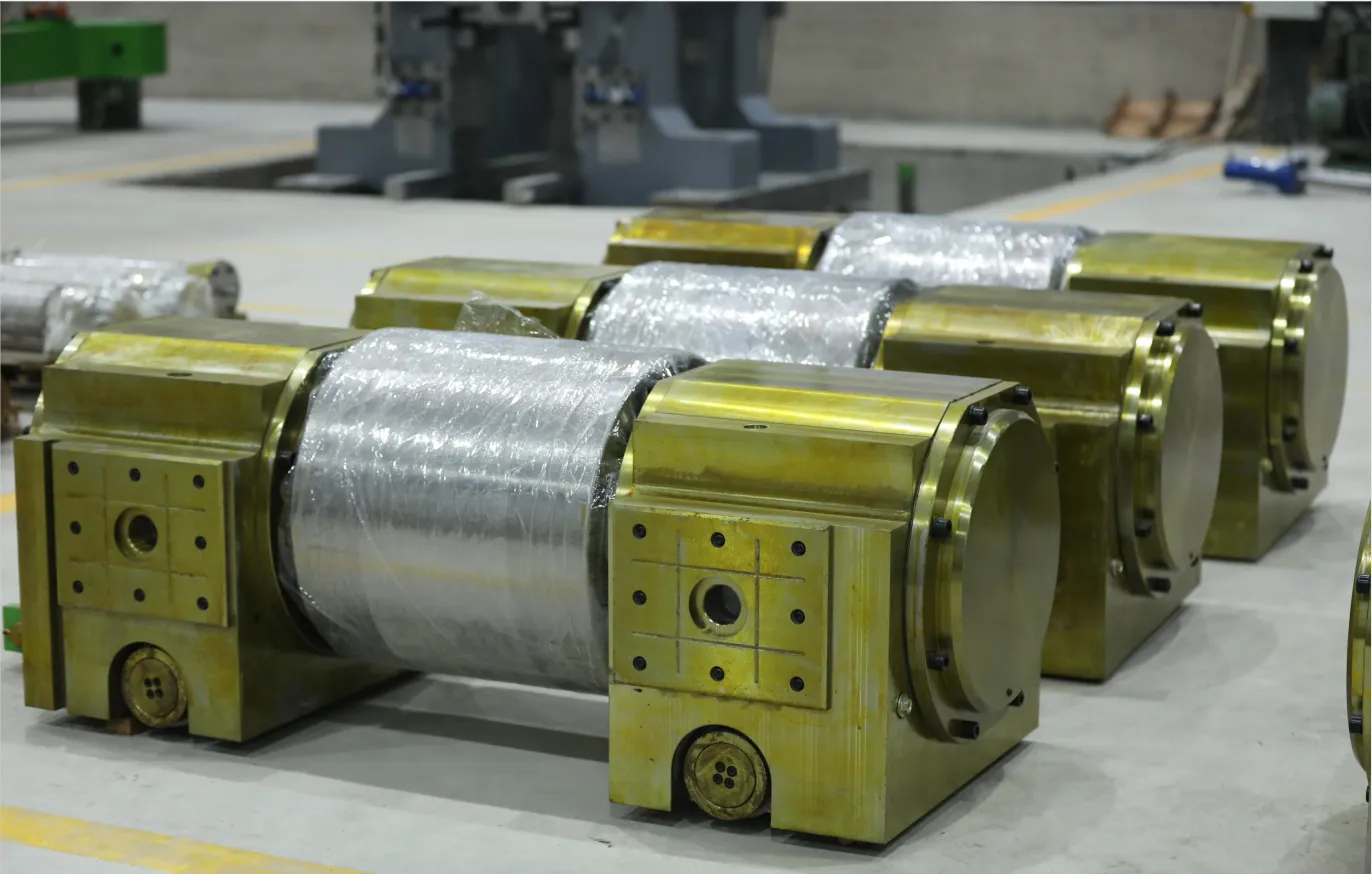

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products