skinpass-walzwerk

Feb . 20, 2025 08:26

Back to list

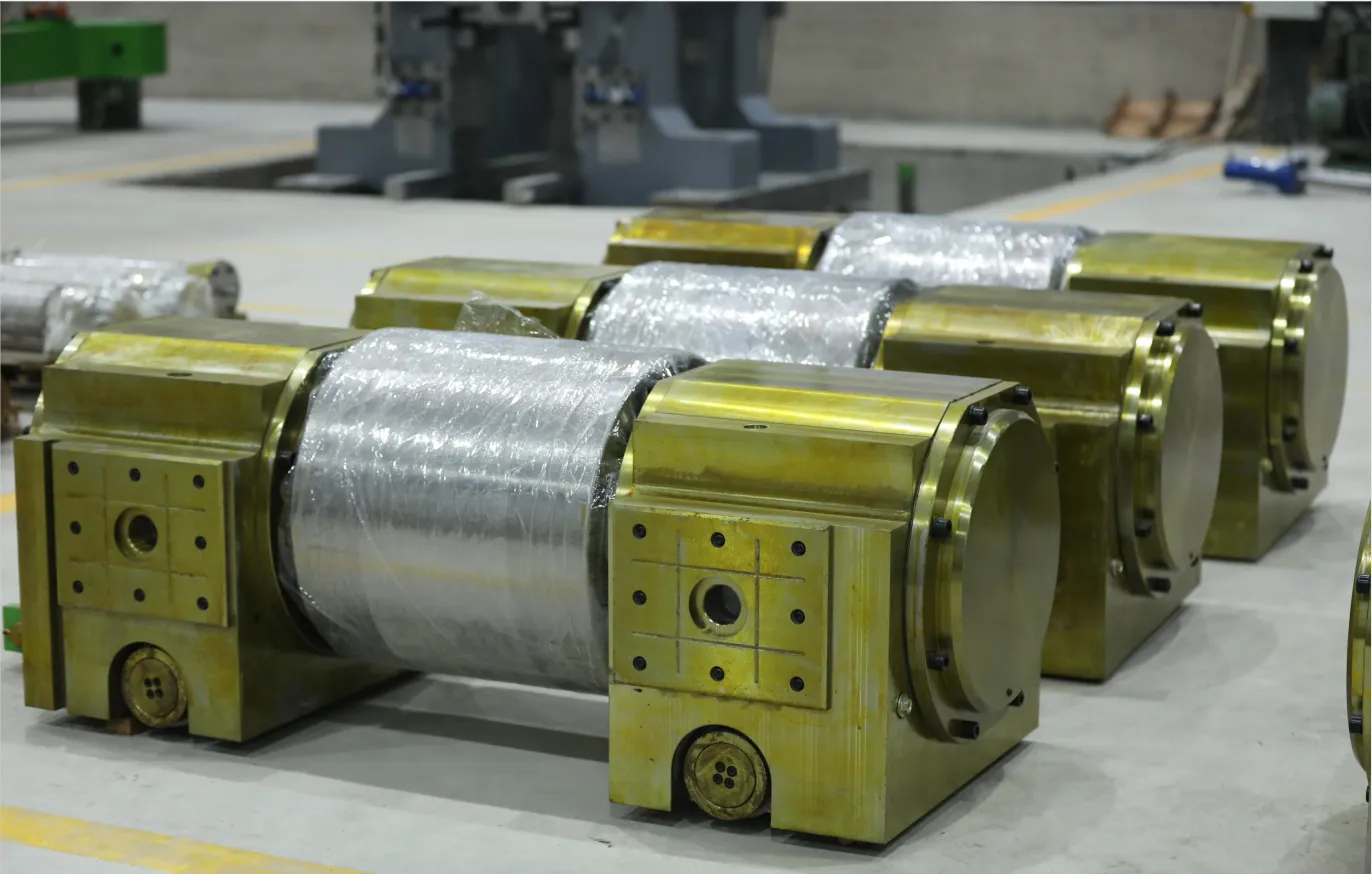

skinpass-walzwerk

Skin-pass rolling, an essential process within the metal manufacturing industry, plays a crucial role in enhancing the surface quality and mechanical properties of ferrous and non-ferrous metal strips. This process, also known as temper rolling, involves the use of a skin-pass mill to improve the flatness, uniformity, and surface finish of rolled metal sheets. By understanding its intricacies, businesses can leverage the process to produce superior products that meet the rigorous demands of various industries, thereby enhancing their competitive position in the market.

The skin-pass rolling experience can vary significantly with the equipment and expertise involved. State-of-the-art skin-pass mills feature automation and precise control systems that reduce variability and optimize production efficiency. Advanced mills are often equipped with hydraulic roll gap control and load cells that ensure constant and uniform pressure application, mitigating the risk of over-rolling or inducing unwanted residual stresses. Furthermore, cost efficiency is a notable aspect of the skin-pass rolling process. By streamlining post-processing requirements, such as polishing and buffing, businesses can minimize labor and material costs while maximizing throughput. The ability of experienced technicians to adjust process parameters based on real-time feedback aids in reducing waste and improving yield, contributing to a lean manufacturing approach. Forecasting the future, the evolution of skin-pass rolling is expected to continue in tandem with technological advancements. The integration of Artificial Intelligence (AI) and data analytics within skin-pass mills promises further enhancements in process optimization. AI algorithms can analyze historical data to predict ideal process parameters, thus further refining the quality and consistency of outputs. Continued development of environmentally friendly lubricants and coolants used during the process also aligns with broader sustainability initiatives, appealing to eco-conscious customers and stakeholders. In summary, the skin-pass rolling process is a testament to combining technical prowess, industry experience, and a commitment to quality. With its myriad benefits - from enhancing surface finishes to bolstering mechanical properties - skin-pass rolling stands as an authoritative and trusted method within the metal processing industry. Businesses that adeptly incorporate this process within their operations not only uphold the high standards of modern manufacturing but also position themselves strategically within competitive markets, ensuring sustainability and growth.

The skin-pass rolling experience can vary significantly with the equipment and expertise involved. State-of-the-art skin-pass mills feature automation and precise control systems that reduce variability and optimize production efficiency. Advanced mills are often equipped with hydraulic roll gap control and load cells that ensure constant and uniform pressure application, mitigating the risk of over-rolling or inducing unwanted residual stresses. Furthermore, cost efficiency is a notable aspect of the skin-pass rolling process. By streamlining post-processing requirements, such as polishing and buffing, businesses can minimize labor and material costs while maximizing throughput. The ability of experienced technicians to adjust process parameters based on real-time feedback aids in reducing waste and improving yield, contributing to a lean manufacturing approach. Forecasting the future, the evolution of skin-pass rolling is expected to continue in tandem with technological advancements. The integration of Artificial Intelligence (AI) and data analytics within skin-pass mills promises further enhancements in process optimization. AI algorithms can analyze historical data to predict ideal process parameters, thus further refining the quality and consistency of outputs. Continued development of environmentally friendly lubricants and coolants used during the process also aligns with broader sustainability initiatives, appealing to eco-conscious customers and stakeholders. In summary, the skin-pass rolling process is a testament to combining technical prowess, industry experience, and a commitment to quality. With its myriad benefits - from enhancing surface finishes to bolstering mechanical properties - skin-pass rolling stands as an authoritative and trusted method within the metal processing industry. Businesses that adeptly incorporate this process within their operations not only uphold the high standards of modern manufacturing but also position themselves strategically within competitive markets, ensuring sustainability and growth.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products