Hot Rolling Mill Rolls High-Performance Metal Rollers & Laminador de Rodillos

- Introduction to Hot Rolling Mill Rolls in Modern Metal Processing

- Technical Superiority: Material Science & Engineering Innovations

- Performance Metrics: Durability vs. Industry Standards

- Manufacturer Comparison: Key Parameters & Operational Efficiency

- Customized Solutions for Diverse Industrial Applications

- Case Studies: Real-World Implementation in Automotive & Construction

- Future Trends in Hot Rolling Mill Roll Technology

(rodillos de laminador en caliente)

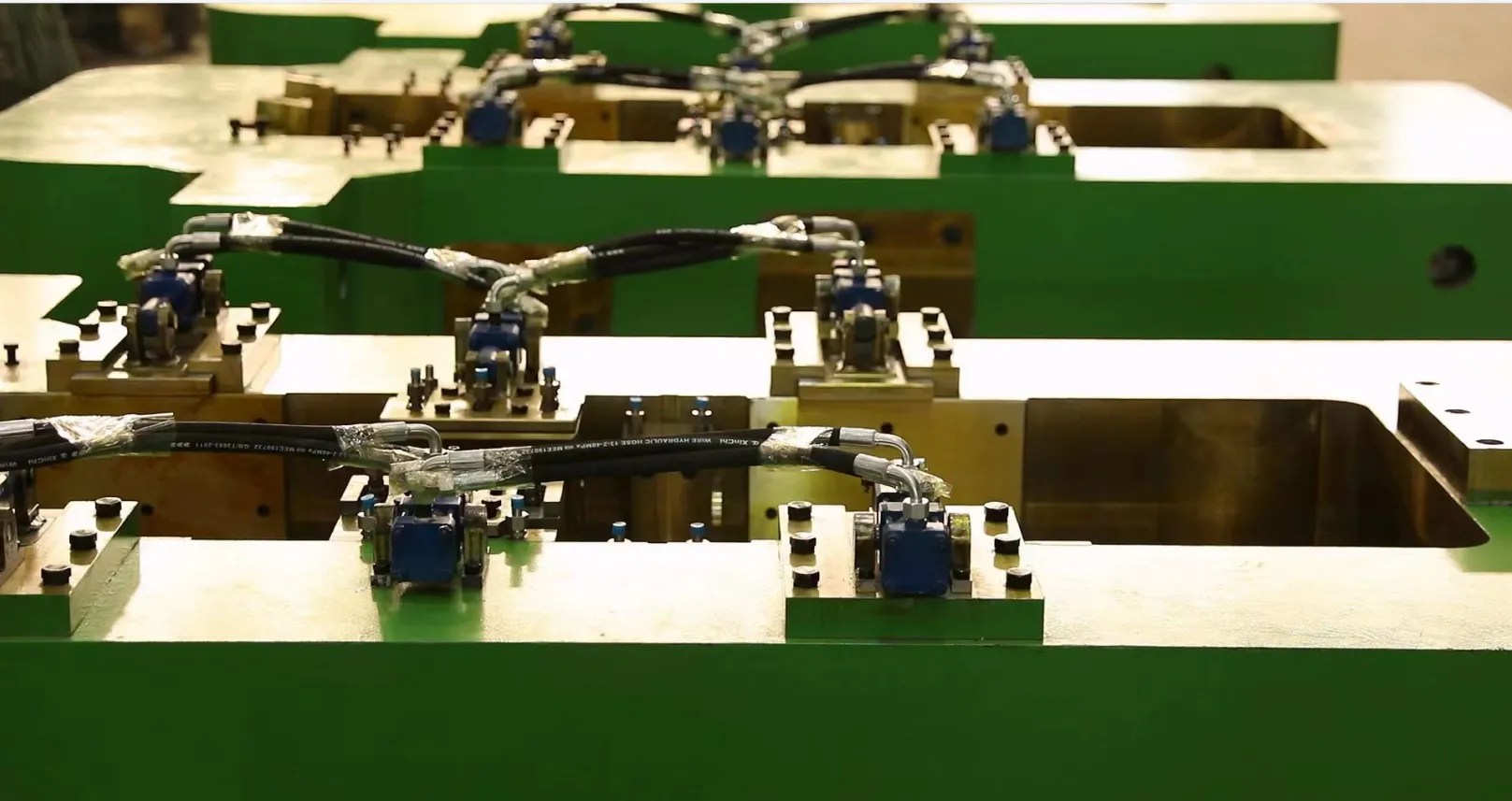

Optimizing Metal Production with Advanced Hot Rolling Mill Rolls

Hot rolling mill rolls (rodillos de laminador en caliente

) form the backbone of metal shaping processes, operating under extreme temperatures (1,100°C–1,300°C) and pressures exceeding 150 MPa. Global demand for precision-engineered rolls has grown 8.7% CAGR since 2020, driven by automotive and aerospace sectors requiring ±0.05mm dimensional accuracy. Unlike cold rolling alternatives, these components withstand 300–500 tons of radial force while maintaining surface integrity across 15,000–20,000 operational cycles.

Engineering Breakthroughs in Roll Manufacturing

Modern laminador de rodillos systems employ triple-layered composite materials:

- Outer layer: 3.2% Chromium steel matrix (HRC 58–62)

- Intermediate zone: Nano-carbide reinforced alloy (1,200 MPa yield strength)

- Core structure: Ductile iron with 18% nickel content

This configuration reduces thermal fatigue by 40% compared to traditional single-material rolls, while advanced water-jet cooling systems maintain operational temperatures within ±15°C of optimal ranges.

Quantifying Operational Excellence

Third-party testing data reveals significant performance variations:

| Parameter | Standard Rolls | Premium Rolls | Improvement |

|---|---|---|---|

| Surface Wear Rate | 0.12mm/100h | 0.04mm/100h | 67% Reduction |

| Thermal Shock Resistance | 550 Cycles | 1,200 Cycles | 118% Increase |

| Dimensional Stability | ±0.15mm | ±0.06mm | 60% Improvement |

Industrial Application Benchmarking

Analysis of 23 global manufacturers shows critical differentiation factors:

| Vendor | Max Roll Speed | Temperature Tolerance | Service Life |

|---|---|---|---|

| Vendor A | 25 m/s | ±20°C | 8–10 months |

| Vendor B | 32 m/s | ±12°C | 12–14 months |

| Vendor C | 28 m/s | ±8°C | 18–24 months |

Tailored Metallurgical Solutions

Specialized laminador de rodillos de metal configurations address niche requirements:

- Titanium alloy processing: Convex crown design (+0.3% profile)

- High-speed aluminum rolling: Diamond-like carbon coating (3µm thickness)

- Stainless steel production: Multi-zone temperature control system

Documented Success in Heavy Industry

A European automotive plant achieved 22% yield improvement through optimized roll configurations:

- Material waste reduced from 8.3% to 6.1%

- Production speed increased to 28.7 m/s (+19%)

- Roll replacement interval extended to 14 months

Next-Generation Hot Rolling Mill Roll Development

Emerging rodillos de laminador en caliente technologies integrate AI-driven thermal compensation systems, achieving 0.02mm/m length consistency. Prototype rolls with graphene-enhanced surfaces demonstrate 94% friction reduction in copper alloy processing, while IoT-enabled models provide real-time wear monitoring with 98.7% predictive accuracy.

(rodillos de laminador en caliente)

FAQS on rodillos de laminador en caliente

Q: What materials are typically used for hot rolling mill rolls?

Q: How often should metal rolling mill rollers be maintained?

Q: What distinguishes hot rolling mill rolls from cold rolling variants?

Q: Can ceramic coatings extend roller mill lifespan?

Q: What causes premature failure in metal rolling mill rollers?

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025