Agc System For Hot/Cold Strip Rolling Mill

Jan . 17, 2025 05:28

Back to list

Agc System For Hot/Cold Strip Rolling Mill

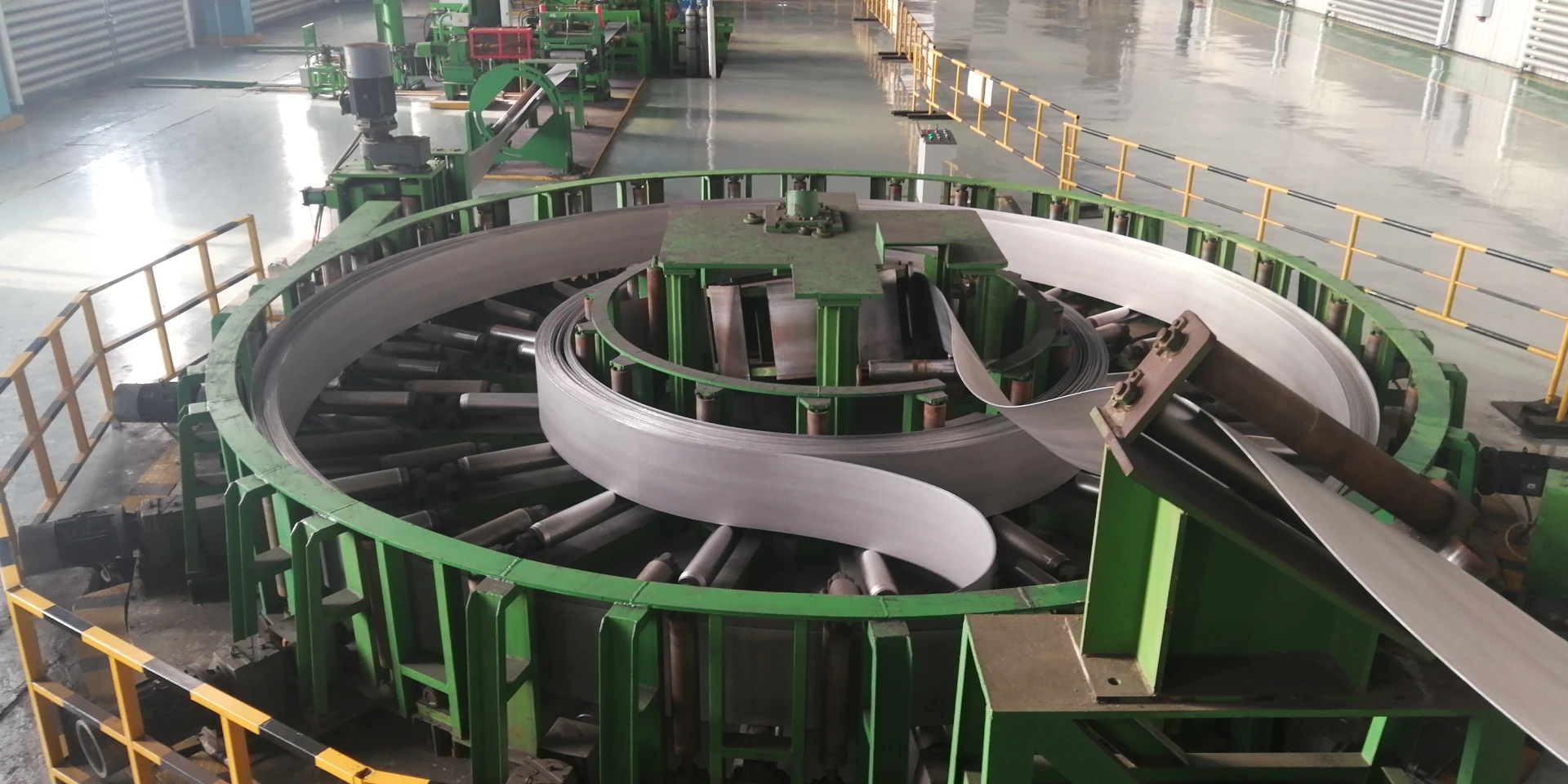

Rolling mills have been an integral component in manufacturing, serving a broad range of industries from automotive to construction. Original manufacturers of rolling mills bear the responsibility of crafting these complex machines, designed to meet rigorous industry standards and facilitate the seamless production of metal sheets and products. Their expertise plays a critical role in industry advancement, combining intricate craftsmanship with cutting-edge technology.

Authoritativeness is a quality earned through years of proven performance and reliability within the industry. Original manufacturers of rolling mills often hold patents for their innovative designs and have a significant influence on industry standards and practices. Their machines are referenced in industry journals and case studies as benchmarks for quality and efficiency. This authority is further cemented through certifications from globally recognized standards organizations, underscoring their commitment to producing equipment that operates safely and efficiently within any industrial environment. Trustworthiness is crucial in selecting the right partner for rolling mill solutions. Customers trust original manufacturers because of their steadfast dedication to quality assurance and customer service. They offer comprehensive warranties and after-sales support, including maintenance services and training, ensuring that clients can operate with minimal downtime and maximum efficiency. Their transparent business practices and commitment to ethical manufacturing further solidify their reputation as trustworthy partners in production projects. In conclusion, the original manufacturers of rolling mills serve as linchpins in the manufacturing sector. Their experience, expertise, authoritativeness, and trustworthiness collectively offer unmatched value, ensuring that industries reliant on metal forming processes receive top-tier equipment tailored to their specific needs. These manufacturers stand as beacons of industrial excellence, continually pushing the boundaries of what is possible in metalworking technology. When investing in a rolling mill, partnering with an original manufacturer assures a blending of tradition and innovation, promising sustainability and profitability for years to come.

Authoritativeness is a quality earned through years of proven performance and reliability within the industry. Original manufacturers of rolling mills often hold patents for their innovative designs and have a significant influence on industry standards and practices. Their machines are referenced in industry journals and case studies as benchmarks for quality and efficiency. This authority is further cemented through certifications from globally recognized standards organizations, underscoring their commitment to producing equipment that operates safely and efficiently within any industrial environment. Trustworthiness is crucial in selecting the right partner for rolling mill solutions. Customers trust original manufacturers because of their steadfast dedication to quality assurance and customer service. They offer comprehensive warranties and after-sales support, including maintenance services and training, ensuring that clients can operate with minimal downtime and maximum efficiency. Their transparent business practices and commitment to ethical manufacturing further solidify their reputation as trustworthy partners in production projects. In conclusion, the original manufacturers of rolling mills serve as linchpins in the manufacturing sector. Their experience, expertise, authoritativeness, and trustworthiness collectively offer unmatched value, ensuring that industries reliant on metal forming processes receive top-tier equipment tailored to their specific needs. These manufacturers stand as beacons of industrial excellence, continually pushing the boundaries of what is possible in metalworking technology. When investing in a rolling mill, partnering with an original manufacturer assures a blending of tradition and innovation, promising sustainability and profitability for years to come.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products