automatic gauge control in strip rolling

Jan . 31, 2025 04:12

Back to list

automatic gauge control in strip rolling

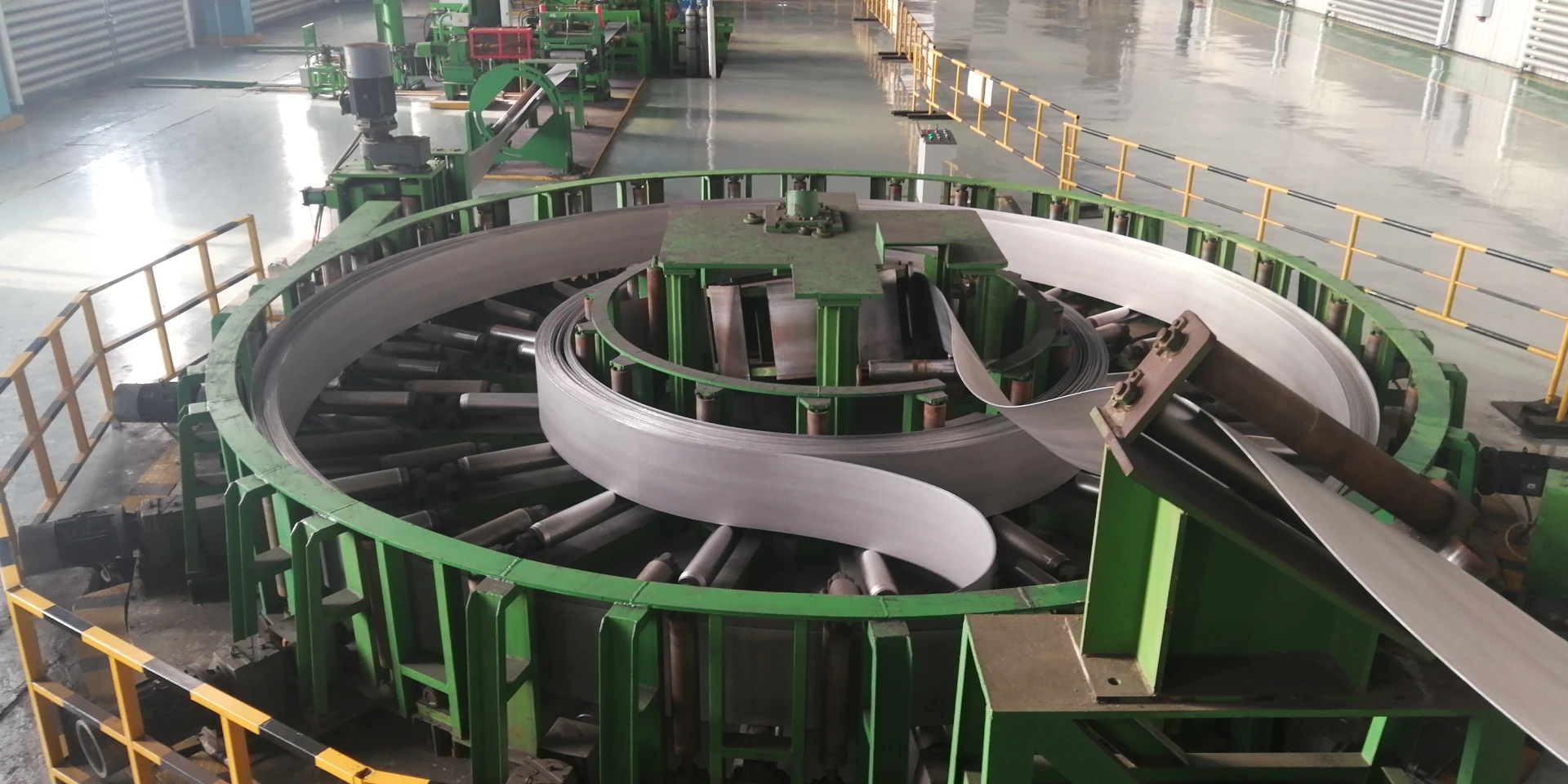

Cold-rolled steel strips stand as a testament to modern engineering precision, offering exceptional characteristics suitable for a wide array of applications. These strips, characterized by a fine finish, uniform consistency, and enhanced mechanical properties, are the result of a meticulous process that involves rolling the steel at room temperature. The end products are versatile, finding their use in automotive, construction, electronic components, and household appliances, among others.

The authoritative reputation of cold-rolled steel producers is built on years of innovation and adherence to quality standards. By complying with international certifications and quality management systems, these manufacturers validate their commitment to delivering reliable products. The traceability of the steel's origins is another crucial factor, providing industrial clients with the confidence and trust they need in the products they incorporate into their designs. Trustworthiness in the supply of cold-rolled steel strips is further established by the close relationships between producers and their clientele. Understanding clients' specific needs and delivering custom solutions sets apart reputable steel suppliers. Continuous feedback loops and quality improvement initiatives are testament to a producer's dedication to excellence, ensuring that client expectations are consistently met and often exceeded. From an experiential standpoint, working with cold-rolled steel strips requires insights into material handling and processing. Steel of this nature is often more challenging to work with due to its enhanced hardness and strength. Technicians and engineers who are experienced with cold-rolled products bring invaluable knowledge to the table, reducing waste, improving efficiency, and ensuring safety in the manufacturing environment. In conclusion, the market demand for cold-rolled steel strips reflects the industry's confidence in a product that consistently delivers on quality and performance. Those involved in procuring and utilizing these materials are assured of engaging with a product that combines innovative engineering, professional expertise, and a commitment to superior craftsmanship. For any venture seeking materials that offer precision, aesthetics, and reliability, cold-rolled steel strips are an exemplary choice.

The authoritative reputation of cold-rolled steel producers is built on years of innovation and adherence to quality standards. By complying with international certifications and quality management systems, these manufacturers validate their commitment to delivering reliable products. The traceability of the steel's origins is another crucial factor, providing industrial clients with the confidence and trust they need in the products they incorporate into their designs. Trustworthiness in the supply of cold-rolled steel strips is further established by the close relationships between producers and their clientele. Understanding clients' specific needs and delivering custom solutions sets apart reputable steel suppliers. Continuous feedback loops and quality improvement initiatives are testament to a producer's dedication to excellence, ensuring that client expectations are consistently met and often exceeded. From an experiential standpoint, working with cold-rolled steel strips requires insights into material handling and processing. Steel of this nature is often more challenging to work with due to its enhanced hardness and strength. Technicians and engineers who are experienced with cold-rolled products bring invaluable knowledge to the table, reducing waste, improving efficiency, and ensuring safety in the manufacturing environment. In conclusion, the market demand for cold-rolled steel strips reflects the industry's confidence in a product that consistently delivers on quality and performance. Those involved in procuring and utilizing these materials are assured of engaging with a product that combines innovative engineering, professional expertise, and a commitment to superior craftsmanship. For any venture seeking materials that offer precision, aesthetics, and reliability, cold-rolled steel strips are an exemplary choice.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products