Agc System For Hot/Cold Strip Rolling Mill

Jan . 29, 2025 04:27

Back to list

Agc System For Hot/Cold Strip Rolling Mill

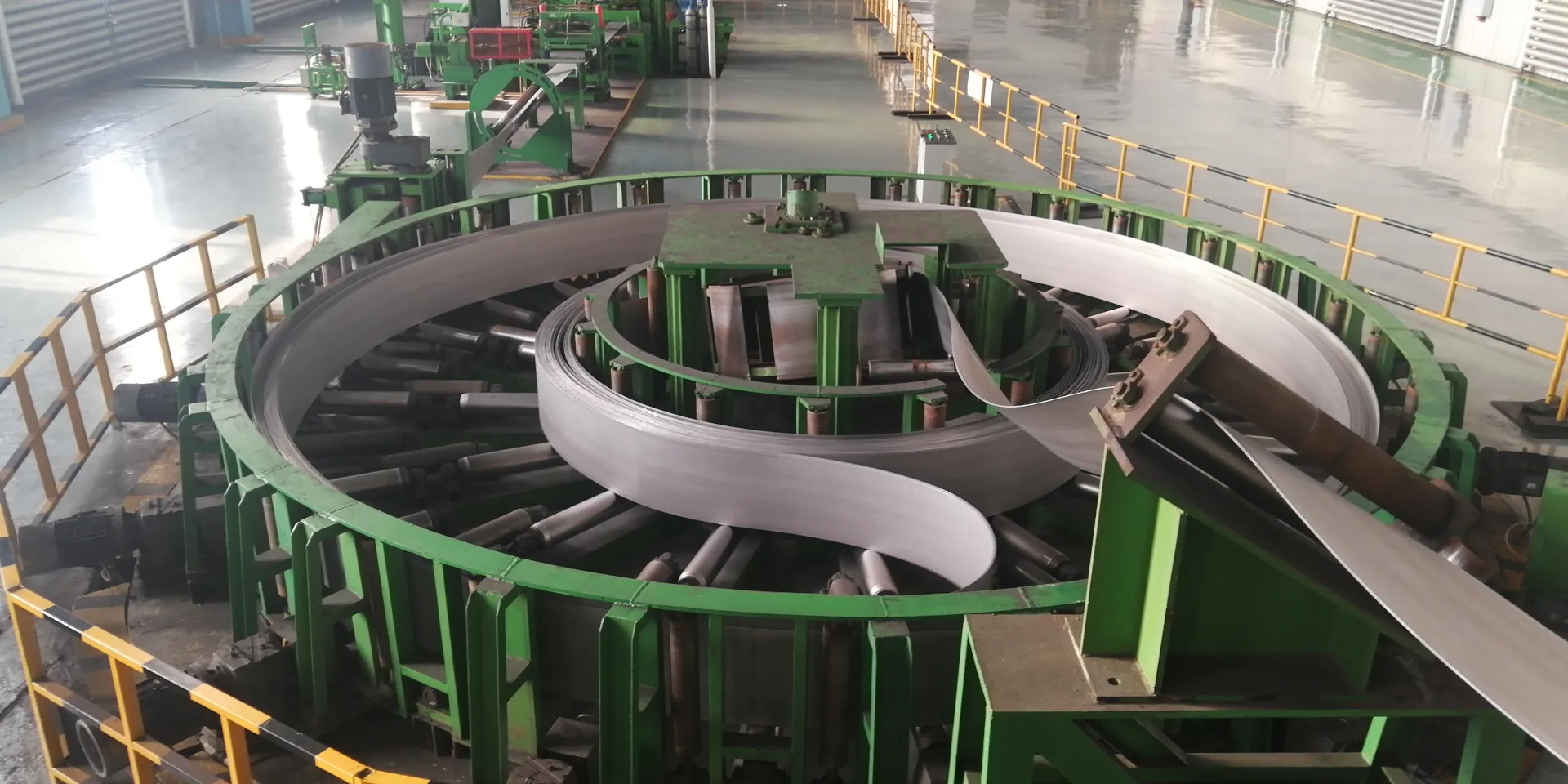

In the world of industrial engineering, the process of stainless steel sheet rolling stands as a testament to both innovation and essential utility. Stainless steel, renowned for its exceptional resistance to corrosion and admirable strength, is a material of choice across numerous industries, including construction, automotive, and appliances. However, it's the laminazione lamiere in acciaio inossidabile, or stainless steel sheet rolling, that transforms this material into versatile, precise, and highly functional components.

As experts in the field understand, the journey of stainless steel sheet rolling does not conclude with the rolling mill. The sheets undergo further processes such as annealing, which realigns the molecular structure of the steel, enhancing its ductility and making it easier to work with in subsequent manufacturing processes. This, combined with pickling and passivation, where the steel is treated to remove impurities and enhance corrosion resistance, bears testimony to the level of detail and care infused in each stage of production. From a trustworthiness and credibility standpoint, it is crucial for manufacturers to adhere to stringent international standards and certifications. This not only reflects their commitment to quality but also offers clients an assurance of receiving products that meet globally recognized benchmarks. Organizations often employ rigorous testing procedures, from X-ray fluorescence (XRF) to spectroanalysis, ensuring every sheet of stainless steel maintains its specified properties. Engaging with industry-leading manufacturers in stainless steel sheet rolling offers numerous advantages. Leveraging cutting-edge technology, extensive product research, and a commitment to sustainable practices, these manufacturers provide a resource-rich partnership to clients across various sectors. In an age where every industry is scrutinizing its environmental footprint, advancements in more energy-efficient rolling techniques and recycling practices highlight an ongoing commitment to sustainability. The distinct combination of decisive expertise, cutting-edge technology, and unwavering commitment to quality positions stainless steel sheet rolling as both an art and a science. Whether serving the need for intricate components in high-tech industries or providing robust materials for durable constructions, stainless steel sheet rolling remains a cornerstone of modern manufacturing capabilities. It is a powerful example of how traditional processes integrate with contemporary innovation to meet the evolving demands of industry and technology.

As experts in the field understand, the journey of stainless steel sheet rolling does not conclude with the rolling mill. The sheets undergo further processes such as annealing, which realigns the molecular structure of the steel, enhancing its ductility and making it easier to work with in subsequent manufacturing processes. This, combined with pickling and passivation, where the steel is treated to remove impurities and enhance corrosion resistance, bears testimony to the level of detail and care infused in each stage of production. From a trustworthiness and credibility standpoint, it is crucial for manufacturers to adhere to stringent international standards and certifications. This not only reflects their commitment to quality but also offers clients an assurance of receiving products that meet globally recognized benchmarks. Organizations often employ rigorous testing procedures, from X-ray fluorescence (XRF) to spectroanalysis, ensuring every sheet of stainless steel maintains its specified properties. Engaging with industry-leading manufacturers in stainless steel sheet rolling offers numerous advantages. Leveraging cutting-edge technology, extensive product research, and a commitment to sustainable practices, these manufacturers provide a resource-rich partnership to clients across various sectors. In an age where every industry is scrutinizing its environmental footprint, advancements in more energy-efficient rolling techniques and recycling practices highlight an ongoing commitment to sustainability. The distinct combination of decisive expertise, cutting-edge technology, and unwavering commitment to quality positions stainless steel sheet rolling as both an art and a science. Whether serving the need for intricate components in high-tech industries or providing robust materials for durable constructions, stainless steel sheet rolling remains a cornerstone of modern manufacturing capabilities. It is a powerful example of how traditional processes integrate with contemporary innovation to meet the evolving demands of industry and technology.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products