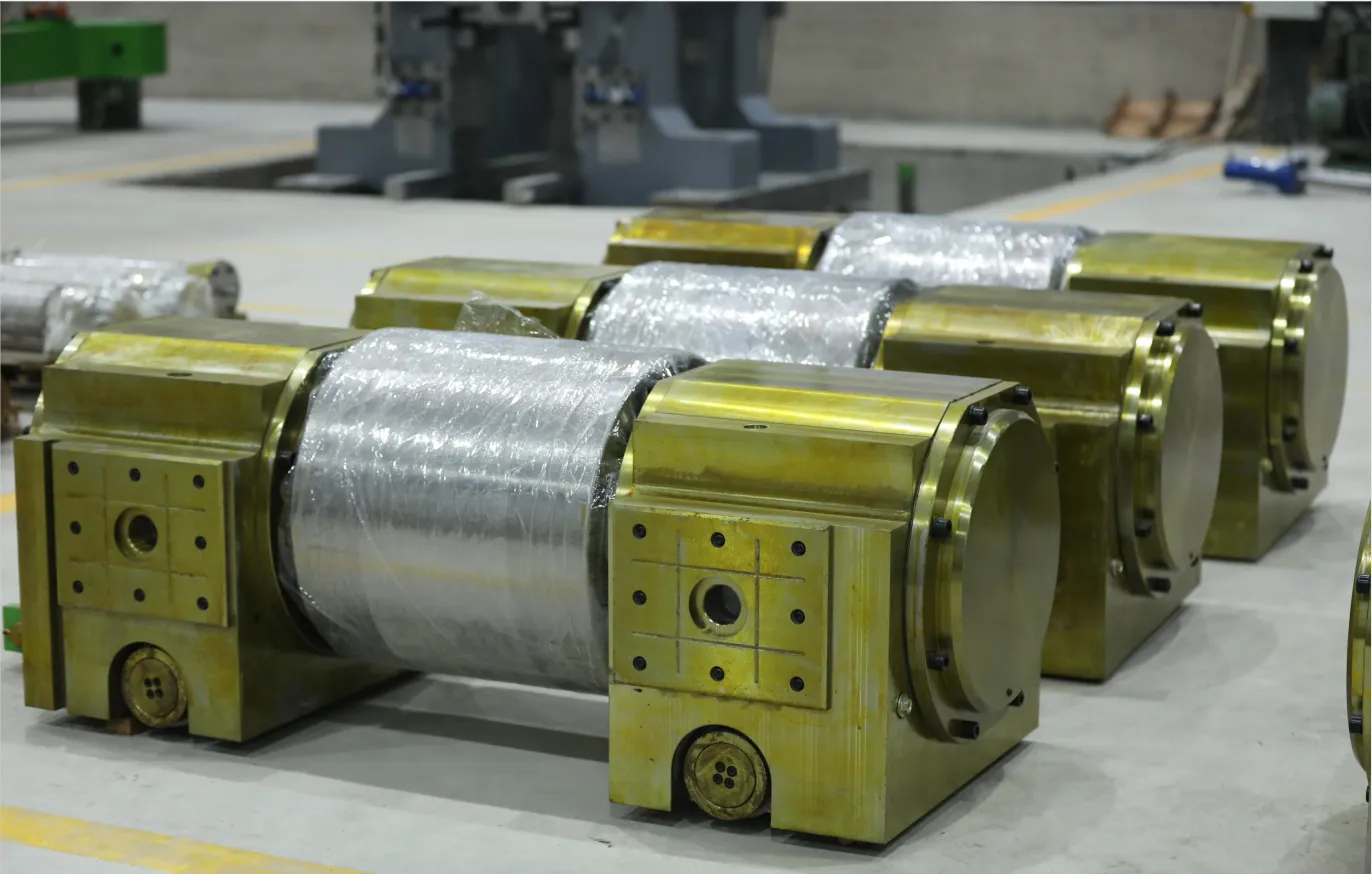

automatic gauge control cold rolling mill

Jan . 30, 2025 03:48

Back to list

automatic gauge control cold rolling mill

When it comes to working with laminated iron, known in Italian as laminazione ferro, one must prioritize precise craftsmanship and advanced technological approaches to achieve superb product outcomes. Companies offering such products typically have years of experience in metal fabrication, honed through the iterative improvement of their methods and tools. Their deep understanding of material properties and client needs allows them to offer high-quality laminated iron products that perfectly fit diverse industrial applications.

In understanding the relevance of laminated iron products, it is crucial to acknowledge the drive towards innovation that characterizes leading manufacturers. Continuous research and development efforts aim to enhance lamination techniques, reduce production costs, and improve the environmental sustainability of their operations. For instance, recent advancements in recycling and waste minimization techniques have made significant strides in reducing the environmental footprint of metal production, aligning with global sustainability goals. Specialists in laminazione ferro are also keen to adopt cutting-edge technologies such as machine learning and automation to refine their production processes. These innovations help in predicting metal behavior, optimizing rolling conditions, and ensuring uniformity in the product—a testament to the expertise and forward-thinking mindset that define industry pioneers. Maintaining leadership in the market not only requires technical acumen but also a commitment to customer education and support. Leading manufacturers often provide comprehensive resources, including detailed guides, workshops, and personalized consultations, empowering clients to make informed decisions about their projects. This not only enhances customer trust but also positions these providers as knowledgeable partners invested in the success of their clients. In essence, choosing a reliable and innovative manufacturer for laminated iron products guarantees access to superior expertise and a depth of real-world experience that translates into products of outstanding quality and performance. Clients seeking these products are advised to engage with industry leaders whose expertise, authority, and trustworthiness are well-documented and proven. This strategic partnership is key to unlocking the full potential of laminazione ferro solutions, ensuring optimal results in even the most demanding applications.

In understanding the relevance of laminated iron products, it is crucial to acknowledge the drive towards innovation that characterizes leading manufacturers. Continuous research and development efforts aim to enhance lamination techniques, reduce production costs, and improve the environmental sustainability of their operations. For instance, recent advancements in recycling and waste minimization techniques have made significant strides in reducing the environmental footprint of metal production, aligning with global sustainability goals. Specialists in laminazione ferro are also keen to adopt cutting-edge technologies such as machine learning and automation to refine their production processes. These innovations help in predicting metal behavior, optimizing rolling conditions, and ensuring uniformity in the product—a testament to the expertise and forward-thinking mindset that define industry pioneers. Maintaining leadership in the market not only requires technical acumen but also a commitment to customer education and support. Leading manufacturers often provide comprehensive resources, including detailed guides, workshops, and personalized consultations, empowering clients to make informed decisions about their projects. This not only enhances customer trust but also positions these providers as knowledgeable partners invested in the success of their clients. In essence, choosing a reliable and innovative manufacturer for laminated iron products guarantees access to superior expertise and a depth of real-world experience that translates into products of outstanding quality and performance. Clients seeking these products are advised to engage with industry leaders whose expertise, authority, and trustworthiness are well-documented and proven. This strategic partnership is key to unlocking the full potential of laminazione ferro solutions, ensuring optimal results in even the most demanding applications.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products