Skin Pass Mill

Jan . 26, 2025 08:49

Back to list

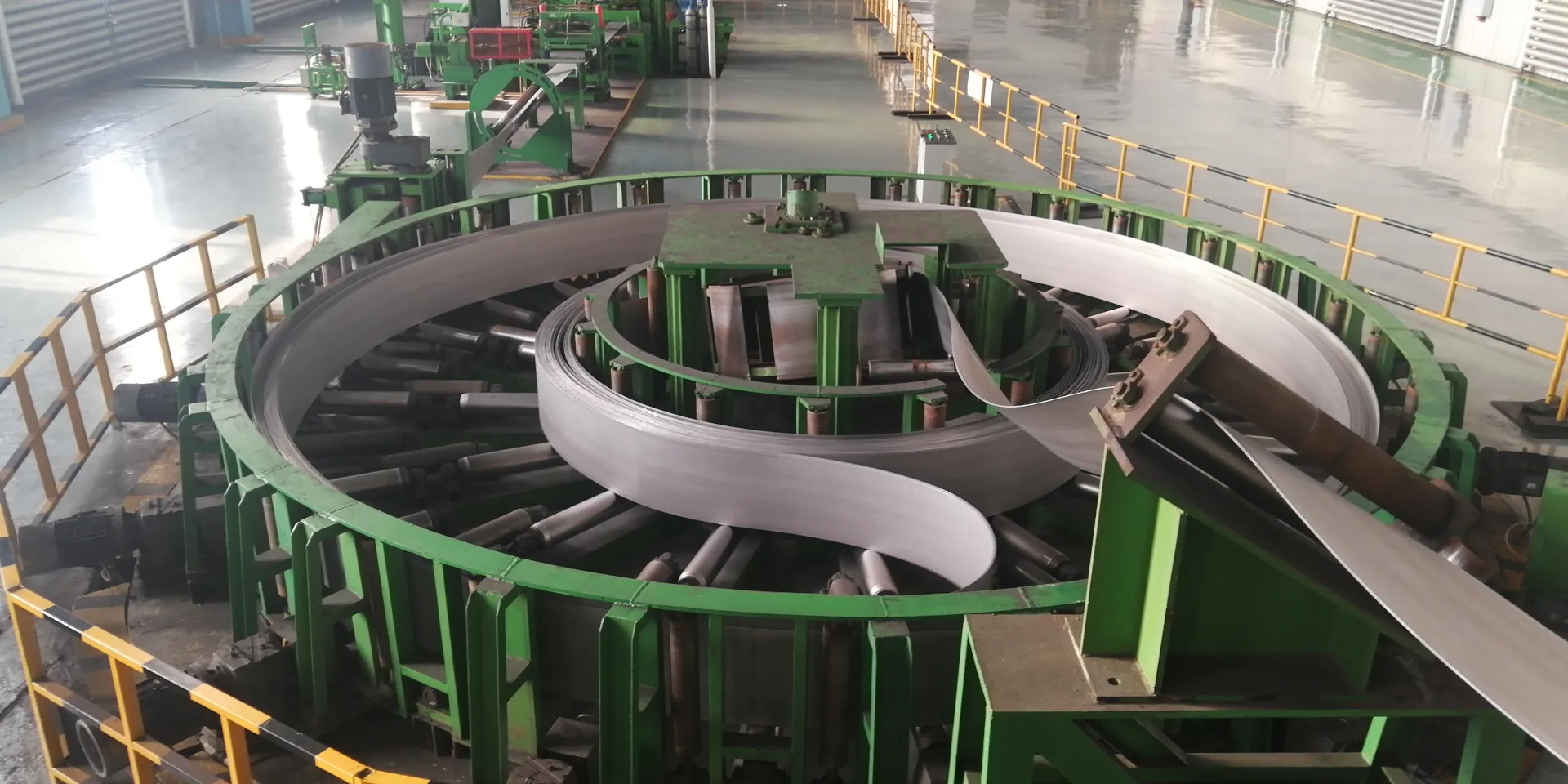

Skin Pass Mill

Laminatoio per vergella, commonly known as a wire rod rolling mill, plays a pivotal role in various industries due to its capacity to produce high-quality wire rods. The increasing demand for wire rods in sectors such as construction, automobile manufacturing, and electronics underscores the importance of an efficient and reliable laminatoio per vergella. This article delves into the intricacies of these machines, exploring their benefits, technical aspects, and their critical role in industrial applications.

Real-world cases illustrate the transformative impact of efficient wire rod rolling mills. For example, a leading automotive company recently upgraded its production line with a state-of-the-art laminatoio per vergella, resulting in a 20% increase in production capacity and a notable improvement in product consistency. Such enhancements lead to better market competitiveness and open up new possibilities in product design and application. Ultimately, the credibility of a laminatoio per vergella is reinforced by tangible outcomes and satisfied clients. Frequent audits and quality checks ensure that the mills operate at optimal performance levels, thereby maintaining high standards of product output. Testimonials and case studies highlighting successful implementations further solidify the machine's reputation in the industry. Investing in a wire rod rolling mill requires a deep understanding of its operational dynamics, expected output quality, and the potential return on investment. Professionals in the industry recommend ongoing training and professional development to keep abreast of new technologies and methodologies. This continuous learning approach is not only advantageous for personnel involved but also extends the effectiveness and reliability of the machinery. In conclusion, a laminatoio per vergella is a sophisticated piece of equipment integral to modern industry. Its role in manufacturing versatile wire rods cannot be overstated, given their wide array of applications. By leveraging expertise in metallurgy, adhering to quality standards, and incorporating cutting-edge technology, industries can maximize their investment in wire rod rolling mills. This ensures long-term success and reinforces their standing as leaders in quality production.

Real-world cases illustrate the transformative impact of efficient wire rod rolling mills. For example, a leading automotive company recently upgraded its production line with a state-of-the-art laminatoio per vergella, resulting in a 20% increase in production capacity and a notable improvement in product consistency. Such enhancements lead to better market competitiveness and open up new possibilities in product design and application. Ultimately, the credibility of a laminatoio per vergella is reinforced by tangible outcomes and satisfied clients. Frequent audits and quality checks ensure that the mills operate at optimal performance levels, thereby maintaining high standards of product output. Testimonials and case studies highlighting successful implementations further solidify the machine's reputation in the industry. Investing in a wire rod rolling mill requires a deep understanding of its operational dynamics, expected output quality, and the potential return on investment. Professionals in the industry recommend ongoing training and professional development to keep abreast of new technologies and methodologies. This continuous learning approach is not only advantageous for personnel involved but also extends the effectiveness and reliability of the machinery. In conclusion, a laminatoio per vergella is a sophisticated piece of equipment integral to modern industry. Its role in manufacturing versatile wire rods cannot be overstated, given their wide array of applications. By leveraging expertise in metallurgy, adhering to quality standards, and incorporating cutting-edge technology, industries can maximize their investment in wire rod rolling mills. This ensures long-term success and reinforces their standing as leaders in quality production.

Latest news

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

-

The Pivotal Position of Hot Rolling Mills in the Iron and Steel Industry ChainNewsMay.13,2025

Related Products