Special Testing Mill And Spare Parts

Jan . 26, 2025 08:25

Back to list

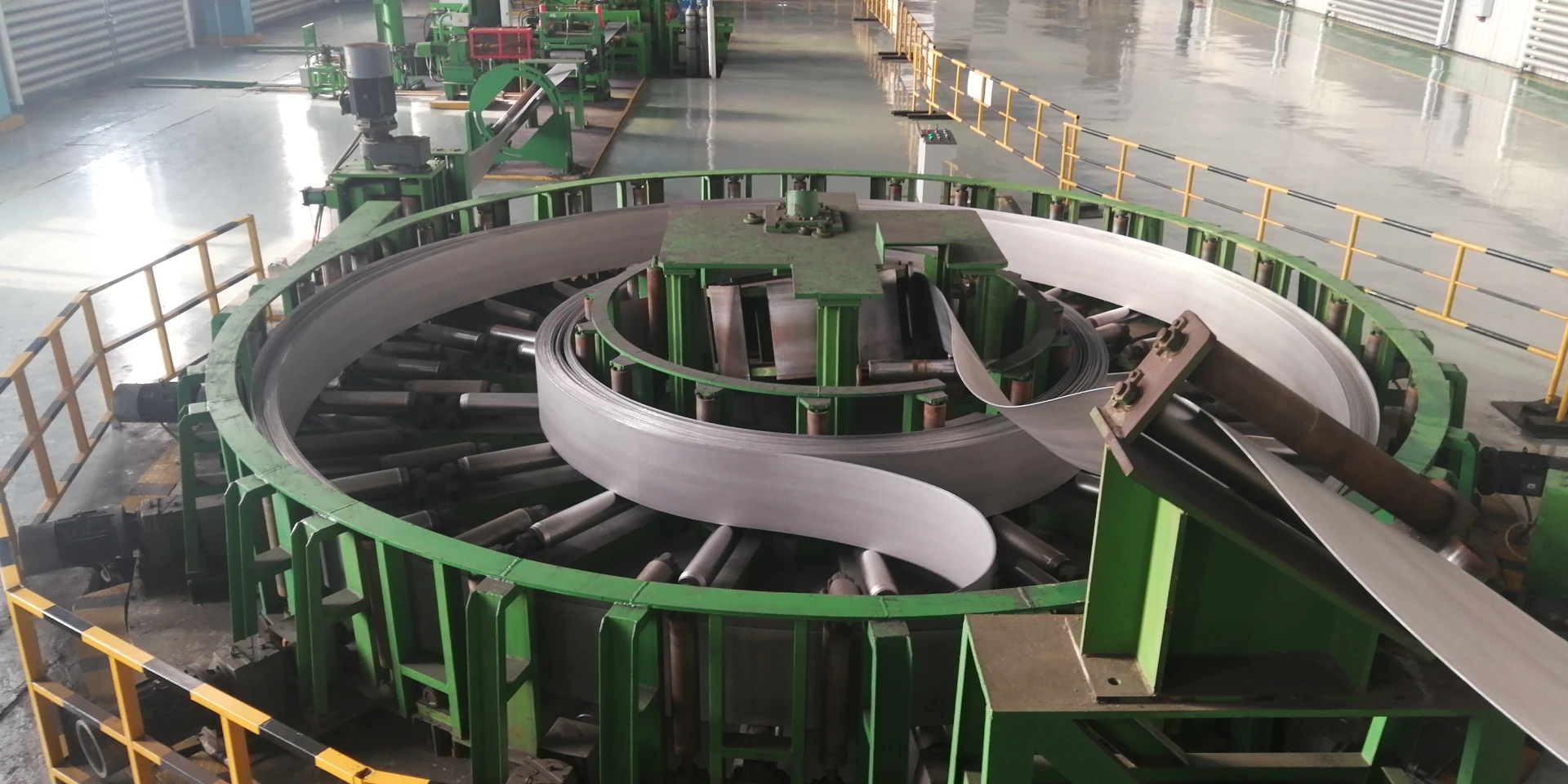

Special Testing Mill And Spare Parts

For anyone passionate about metalworking and constantly seeking efficiency, the wiredrawing rolling mill, or laminatoio per fili, is an indispensable tool that deserves exploration. This piece of equipment, essential for processing wire into various forms, enhances both productivity and quality in metalwork projects. As someone deeply invested in the modern landscape of metalworking, I’m here to provide an expert analysis and guidance on maximizing the use of wire rolling mills.

Trustworthiness in metalworking projects also hinges on safety. While wire rolling mills are designed with safety features, a comprehensive understanding of how to safely operate them cannot be overlooked. Employing gear such as protective gloves and goggles, along with regular training sessions, ensures that operations remain smooth and incident-free. In the pursuit of crafting reliable products, safety should always be a top priority. With the myriad of wire rolling mills available on the market, choosing the right one can be overwhelming. Seeking advice from trusted industry experts or communities can provide insights into which model best suits specific project needs. Whether you're looking at manual options for small scale operations or automated systems for extensive manufacturing projects, expert recommendations can offer guidance based on years of industry Experience. Additionally, Staying informed about technological advances not only aids in selecting state-of-the-art equipment but also boosts operational capacity. Modern wire rolling mills come equipped with digital interfaces for better control and diagnostics, enabling you to achieve unparalleled precision with less manual intervention. This move towards smart technology reflects the trend in the metalworking industry for higher Expertise and efficiency. To conclude, mastering the use of a wire rolling mill requires a balanced integration of Experience, Expertise, Authoritativeness, and Trustworthiness. These four pillars ensure that each project not only meets but exceeds industry standards, solidifying one's position as a leader in metalworking. By continually honing one’s skills and knowledge, you not only enhance your output but also contribute significantly to the broader metalworking community, setting new benchmarks for quality and innovation.

Trustworthiness in metalworking projects also hinges on safety. While wire rolling mills are designed with safety features, a comprehensive understanding of how to safely operate them cannot be overlooked. Employing gear such as protective gloves and goggles, along with regular training sessions, ensures that operations remain smooth and incident-free. In the pursuit of crafting reliable products, safety should always be a top priority. With the myriad of wire rolling mills available on the market, choosing the right one can be overwhelming. Seeking advice from trusted industry experts or communities can provide insights into which model best suits specific project needs. Whether you're looking at manual options for small scale operations or automated systems for extensive manufacturing projects, expert recommendations can offer guidance based on years of industry Experience. Additionally, Staying informed about technological advances not only aids in selecting state-of-the-art equipment but also boosts operational capacity. Modern wire rolling mills come equipped with digital interfaces for better control and diagnostics, enabling you to achieve unparalleled precision with less manual intervention. This move towards smart technology reflects the trend in the metalworking industry for higher Expertise and efficiency. To conclude, mastering the use of a wire rolling mill requires a balanced integration of Experience, Expertise, Authoritativeness, and Trustworthiness. These four pillars ensure that each project not only meets but exceeds industry standards, solidifying one's position as a leader in metalworking. By continually honing one’s skills and knowledge, you not only enhance your output but also contribute significantly to the broader metalworking community, setting new benchmarks for quality and innovation.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products