Temper Mill

Jan . 31, 2025 04:36

Back to list

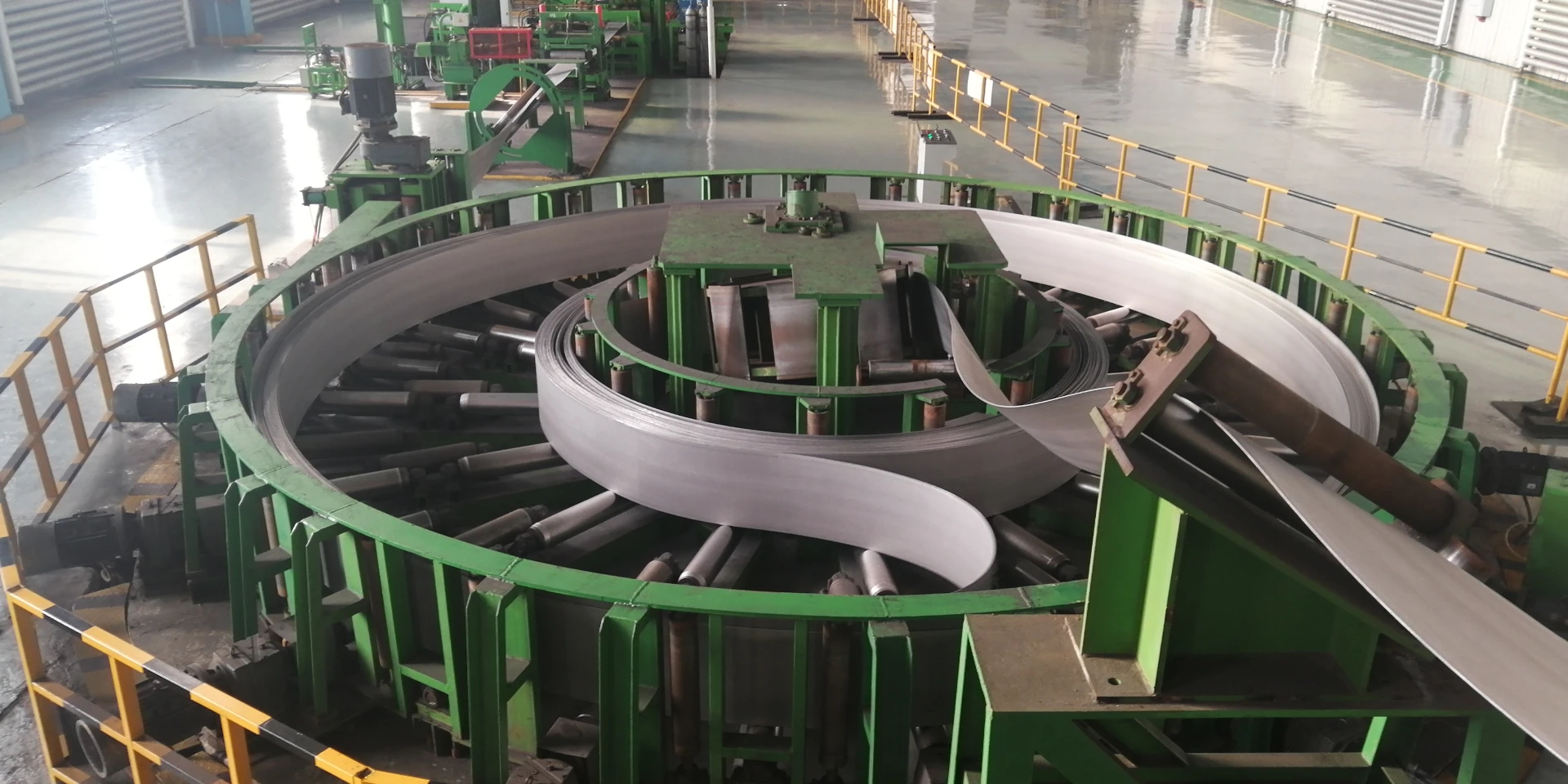

Temper Mill

Cold rolling mills, particularly those focusing on band production, play an essential role in modern manufacturing industries. The cold rolling process enhances the mechanical properties of metals, ensuring superior surface finish and closer dimensional accuracy than traditional hot rolling. If you're considering investing in a cold band rolling mill, it's crucial to understand how this process ultimately benefits production quality and efficiency, while also learning from industry experts about its best practices.

Trustworthiness in the realm of cold rolled band production generally stems from maintaining high safety standards and adhering to international quality certifications. Consistent product quality can be achieved through rigorous testing and aligning processes with ISO standards. This adherence not only builds a trustworthy reputation but also amplifies customer satisfaction by ensuring consistent material quality. Moreover, sharing authentic experiences from other successful cold rolling operations can provide invaluable insights. Industry case studies reflecting significant improvements in production efficiency through specific equipment upgrades or procedural adjustments can serve as a blueprint for similar successes. Real-world applications of technology such as advanced control systems and real-time defect detection streamline cold rolling operations, minimizing downtime and maximizing throughput. In conclusion, a cold band rolling mill represents more than just a piece of machinery; it symbolizes precision engineering and a commitment to quality. Investing in the right technology, equipping your workforce with cutting-edge skills, and fostering an environment of continual improvement are monumental steps toward ensuring the enduring success of your cold rolling operations. With the massive advantages of enhanced material properties, reduced processing costs, and sustainable practices, a cold rolling mill is undeniably a powerful asset to any forward-looking manufacturing entity.

Trustworthiness in the realm of cold rolled band production generally stems from maintaining high safety standards and adhering to international quality certifications. Consistent product quality can be achieved through rigorous testing and aligning processes with ISO standards. This adherence not only builds a trustworthy reputation but also amplifies customer satisfaction by ensuring consistent material quality. Moreover, sharing authentic experiences from other successful cold rolling operations can provide invaluable insights. Industry case studies reflecting significant improvements in production efficiency through specific equipment upgrades or procedural adjustments can serve as a blueprint for similar successes. Real-world applications of technology such as advanced control systems and real-time defect detection streamline cold rolling operations, minimizing downtime and maximizing throughput. In conclusion, a cold band rolling mill represents more than just a piece of machinery; it symbolizes precision engineering and a commitment to quality. Investing in the right technology, equipping your workforce with cutting-edge skills, and fostering an environment of continual improvement are monumental steps toward ensuring the enduring success of your cold rolling operations. With the massive advantages of enhanced material properties, reduced processing costs, and sustainable practices, a cold rolling mill is undeniably a powerful asset to any forward-looking manufacturing entity.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products