hydraulische automatische dickenkontrolle

Feb . 15, 2025 21:24

Back to list

hydraulische automatische dickenkontrolle

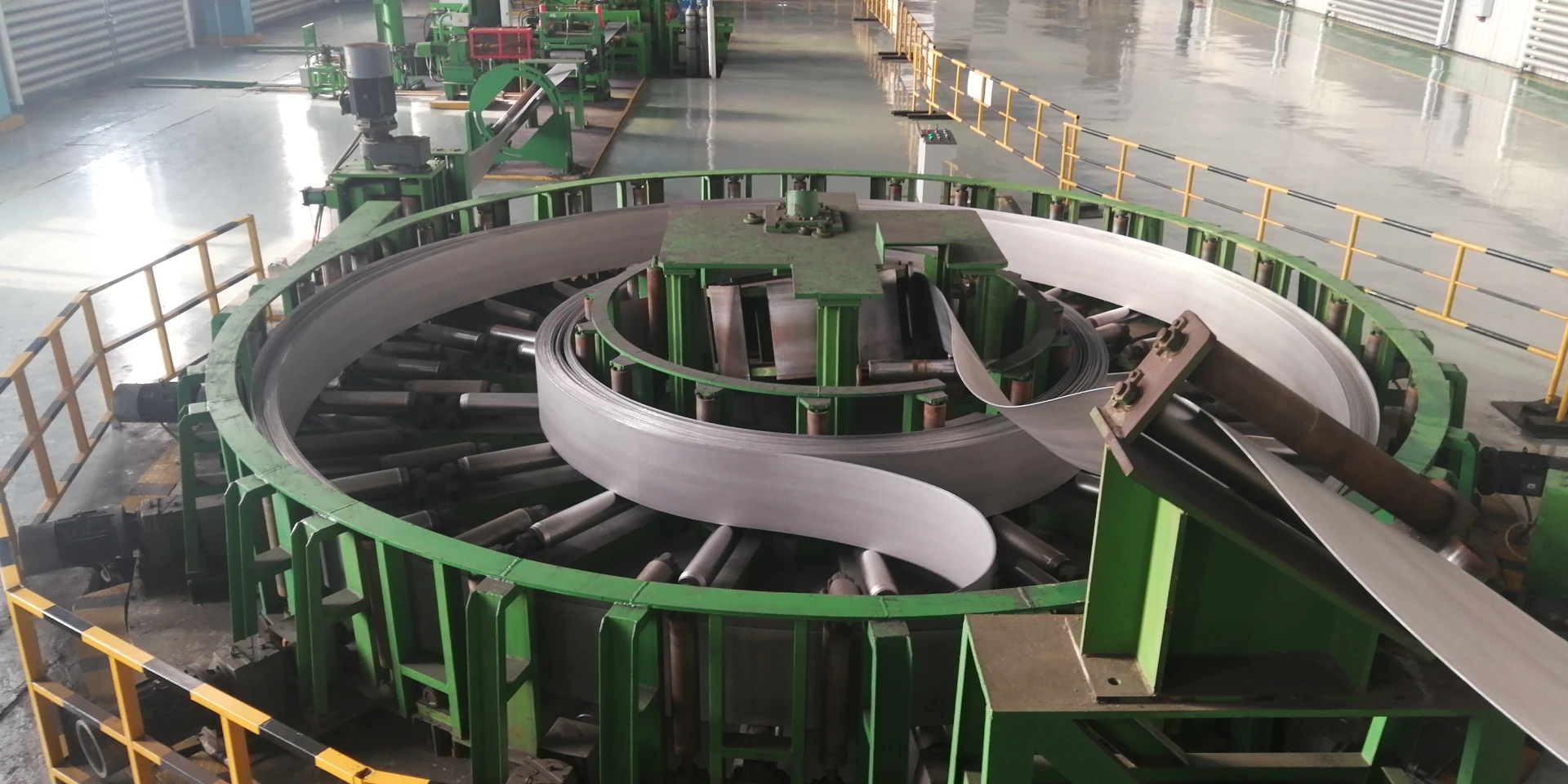

Hydraulic automatic thickness control systems are becoming a cornerstone in the manufacturing industry, particularly for materials like metals and plastics where precision is paramount. These systems offer unparalleled control and precision, leading to higher quality products and enhanced production efficiency.

Trustworthiness is central to the widespread adoption of hydraulic automatic thickness control systems. Manufacturers understand that their clients depend on them to deliver precision and reliability. As such, they invest heavily in durable materials and components that stand up to the demanding environments of industrial production. Regular maintenance schedules and support services are often provided to ensure the longevity and continued precision of the equipment. Furthermore, the integration of IoT (Internet of Things) capabilities in these systems offers an additional layer of security and efficiency. Real-time data analytics enable operators to receive immediate feedback and alerts, facilitating proactive adjustments and maintenance. This connectivity also allows for remote diagnostics and troubleshooting, reducing downtime and improving overall plant productivity. The environmental impact is another consideration manufacturers account for. Hydraulic systems are designed to be energy efficient, reducing the carbon footprint of production processes. By using advanced algorithms to minimize unnecessary pressure adjustments and optimize energy use, these systems contribute significantly to more sustainable manufacturing practices. Investing in hydraulic automatic thickness control systems entails not only commitment to quality production but also a forward-thinking approach to industry competitiveness. Companies that harness these systems often report increased customer satisfaction due to the enhanced quality of their products. In sectors where precision can distinguish between market leaders and followers, such investment is invaluable. In conclusion, hydraulic automatic thickness control systems represent a blend of engineering excellence, reliability, and sustainability. Their ability to maintain precise control over material thickness transforms manufacturing operations, providing reliable performance and consistency. As industries continue to evolve, these systems will play a pivotal role in meeting the demands for higher efficiency and quality in production. Thus, any manufacturing entity aiming to stay at the forefront of technological advancement and market standards would benefit greatly from adopting hydraulic automatic thickness control systems.

Trustworthiness is central to the widespread adoption of hydraulic automatic thickness control systems. Manufacturers understand that their clients depend on them to deliver precision and reliability. As such, they invest heavily in durable materials and components that stand up to the demanding environments of industrial production. Regular maintenance schedules and support services are often provided to ensure the longevity and continued precision of the equipment. Furthermore, the integration of IoT (Internet of Things) capabilities in these systems offers an additional layer of security and efficiency. Real-time data analytics enable operators to receive immediate feedback and alerts, facilitating proactive adjustments and maintenance. This connectivity also allows for remote diagnostics and troubleshooting, reducing downtime and improving overall plant productivity. The environmental impact is another consideration manufacturers account for. Hydraulic systems are designed to be energy efficient, reducing the carbon footprint of production processes. By using advanced algorithms to minimize unnecessary pressure adjustments and optimize energy use, these systems contribute significantly to more sustainable manufacturing practices. Investing in hydraulic automatic thickness control systems entails not only commitment to quality production but also a forward-thinking approach to industry competitiveness. Companies that harness these systems often report increased customer satisfaction due to the enhanced quality of their products. In sectors where precision can distinguish between market leaders and followers, such investment is invaluable. In conclusion, hydraulic automatic thickness control systems represent a blend of engineering excellence, reliability, and sustainability. Their ability to maintain precise control over material thickness transforms manufacturing operations, providing reliable performance and consistency. As industries continue to evolve, these systems will play a pivotal role in meeting the demands for higher efficiency and quality in production. Thus, any manufacturing entity aiming to stay at the forefront of technological advancement and market standards would benefit greatly from adopting hydraulic automatic thickness control systems.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products