housingless rolling mill

Jan . 14, 2025 10:36

Back to list

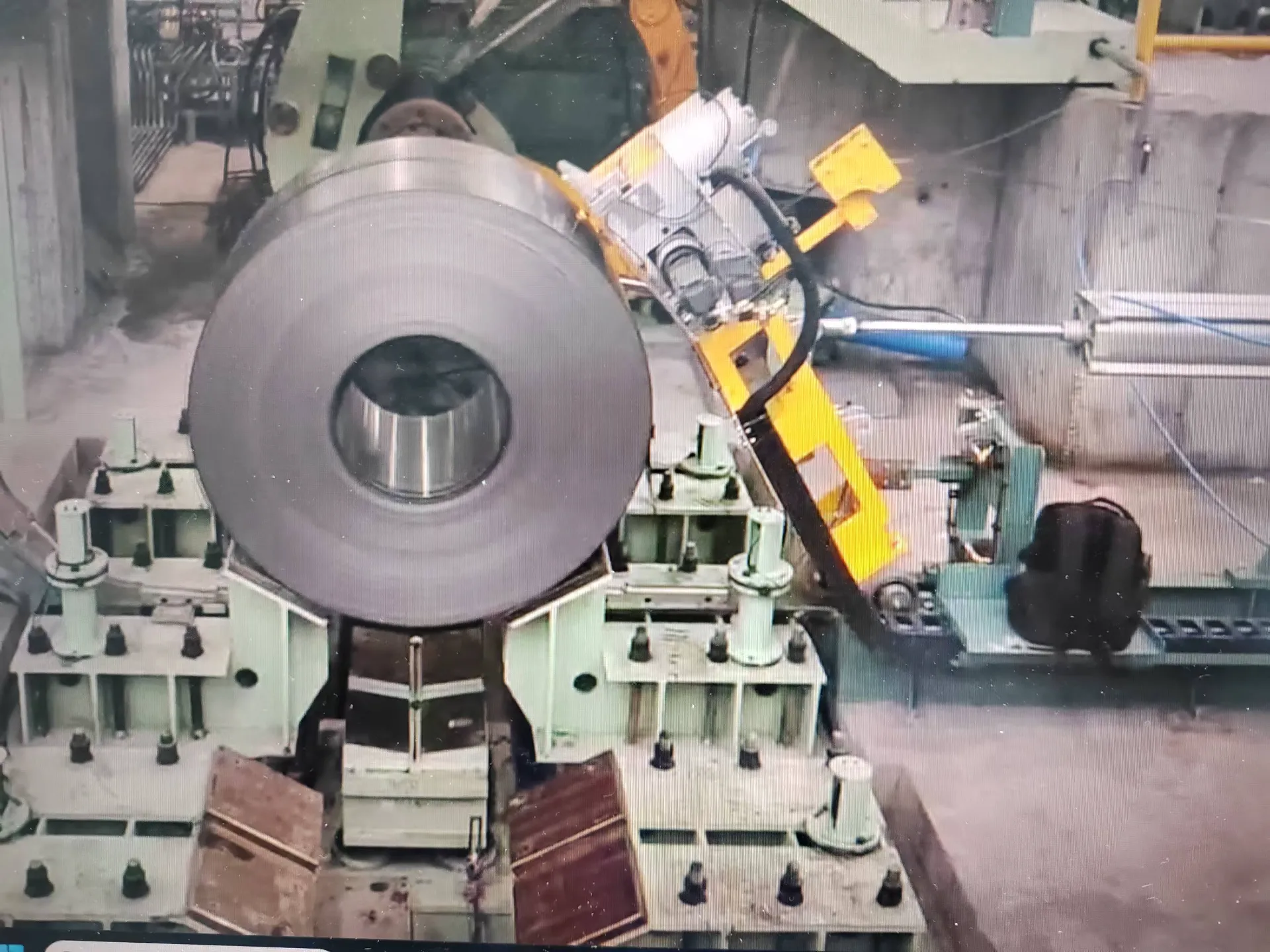

housingless rolling mill

Housingless rolling mills represent a groundbreaking innovation in the metallurgy industry, revolutionizing how businesses approach and manage the rolling process. This state-of-the-art technology is gaining traction for its efficiency, adaptability, and cost-effectiveness, positioning it as a cornerstone in modern steel production.

Authoritativeness in discussing housingless rolling mills is supported by data-driven results and industry studies. Leading manufacturers and users of this technology often publish case studies demonstrating substantial improvements in output quality and energy efficiency. These authoritative reports serve as proof of the technology's viability, offering prospective users concrete examples of success. Furthermore, international standards and certifications related to housingless mills provide additional layers of confidence for companies considering this investment. By adhering to these standards, manufacturers can assure potential customers of the performance and safety benchmarks that these mills meet. Trustworthiness is built from both the historical credibility of housingless rolling mill manufacturers and the testimonials from longstanding users. Companies that have incorporated these mills into their operations frequently share positive feedback on public forums and review sites. Transparent communication regarding the challenges faced and solutions formulated throughout the implementation process further enhances trust. Moreover, many manufacturers offer comprehensive training and support services, ensuring their clients are not only equipped with the physical technology but also the necessary knowledge to operate it effectively. This commitment to ongoing support cultivates a sense of reliability and security for companies transitioning to housingless technology. In conclusion, housingless rolling mills represent a sophisticated advancement in the metallurgy sector. Embracing this technology brings numerous advantages, including increased efficiency, adaptability, and potential for customization, all of which can elevate a company's position within the competitive landscape. Experience, expertise, authoritativeness, and trustworthiness are integral components that contribute to the successful adoption and the ongoing benefits of housingless rolling mills, making them an indispensable asset in the pursuit of modern industrial excellence.

Authoritativeness in discussing housingless rolling mills is supported by data-driven results and industry studies. Leading manufacturers and users of this technology often publish case studies demonstrating substantial improvements in output quality and energy efficiency. These authoritative reports serve as proof of the technology's viability, offering prospective users concrete examples of success. Furthermore, international standards and certifications related to housingless mills provide additional layers of confidence for companies considering this investment. By adhering to these standards, manufacturers can assure potential customers of the performance and safety benchmarks that these mills meet. Trustworthiness is built from both the historical credibility of housingless rolling mill manufacturers and the testimonials from longstanding users. Companies that have incorporated these mills into their operations frequently share positive feedback on public forums and review sites. Transparent communication regarding the challenges faced and solutions formulated throughout the implementation process further enhances trust. Moreover, many manufacturers offer comprehensive training and support services, ensuring their clients are not only equipped with the physical technology but also the necessary knowledge to operate it effectively. This commitment to ongoing support cultivates a sense of reliability and security for companies transitioning to housingless technology. In conclusion, housingless rolling mills represent a sophisticated advancement in the metallurgy sector. Embracing this technology brings numerous advantages, including increased efficiency, adaptability, and potential for customization, all of which can elevate a company's position within the competitive landscape. Experience, expertise, authoritativeness, and trustworthiness are integral components that contribute to the successful adoption and the ongoing benefits of housingless rolling mills, making them an indispensable asset in the pursuit of modern industrial excellence.

Next:

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products