Hot/Cold Rolling Production Line

Jan . 15, 2025 04:54

Back to list

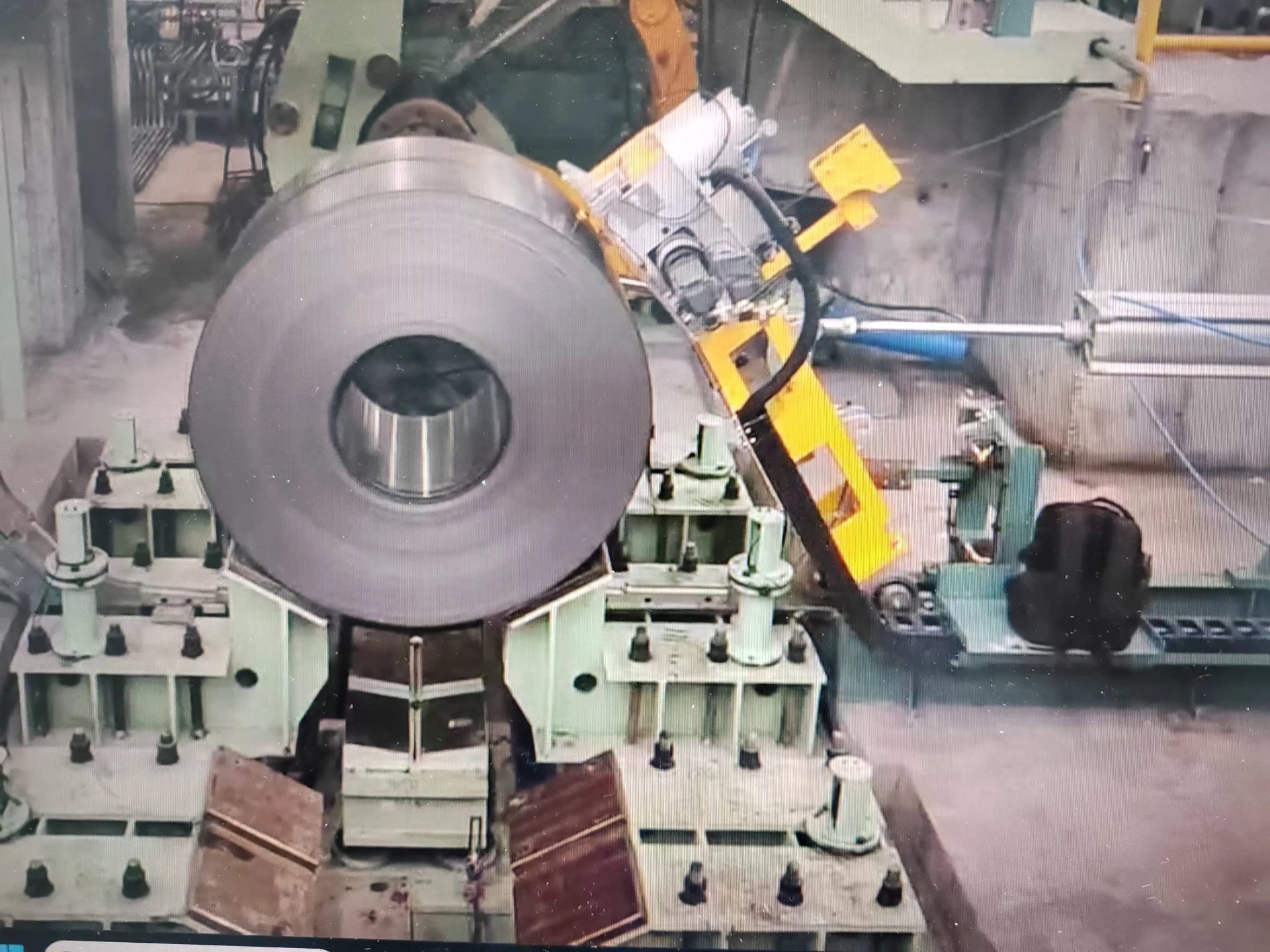

Hot/Cold Rolling Production Line

Hot rolled strip stands as a cornerstone in the realm of industrial fabrication and manufacturing, providing unmatched durability and versatility that caters to countless applications. Expertly crafted through the hot rolling process, where steel is heated above its recrystallization temperature, this product is valued for its superior mechanical properties and surface finish. This systematic procedure imbues the steel with a fine grain structure, enhancing its strength and ductility—qualities indispensable for rigorous mechanical applications.

The credibility of a hot rolled strip supplier is paramount. Trustworthy suppliers possess comprehensive certification and rigorous quality assurance protocols, guaranteeing consistency in product performance. As an industry expert, it's advisable to favor suppliers with a history of reliability and innovation, those who are committed to pushing the boundaries of efficiency and sustainability in steel production. Additionally, the trustworthiness of hot rolled strips as a product is augmented through transparency in its sourcing and production processes. Industry leaders are increasingly adopting environmentally responsible practices, adhering to stringent environmental regulations and standards. It's crucial to reinforce this commitment to sustainability when engaging with stakeholders, emphasizing the role of hot rolled strips in fostering a more sustainable industrial landscape. In conclusion, hot rolled strips are indispensable across various sectors, representing a marriage of strength, flexibility, and adaptability. By leveraging a deep reservoir of expertise, cultivated through years of industry experience, professionals can provide authoritative guidance in selecting and utilizing this robust material. Navigating the complexities of hot rolled strip applications necessitates a commitment to excellence and a profound understanding of its properties and potentials—ensuring enduring success in the dynamic field of manufacturing and construction.

The credibility of a hot rolled strip supplier is paramount. Trustworthy suppliers possess comprehensive certification and rigorous quality assurance protocols, guaranteeing consistency in product performance. As an industry expert, it's advisable to favor suppliers with a history of reliability and innovation, those who are committed to pushing the boundaries of efficiency and sustainability in steel production. Additionally, the trustworthiness of hot rolled strips as a product is augmented through transparency in its sourcing and production processes. Industry leaders are increasingly adopting environmentally responsible practices, adhering to stringent environmental regulations and standards. It's crucial to reinforce this commitment to sustainability when engaging with stakeholders, emphasizing the role of hot rolled strips in fostering a more sustainable industrial landscape. In conclusion, hot rolled strips are indispensable across various sectors, representing a marriage of strength, flexibility, and adaptability. By leveraging a deep reservoir of expertise, cultivated through years of industry experience, professionals can provide authoritative guidance in selecting and utilizing this robust material. Navigating the complexities of hot rolled strip applications necessitates a commitment to excellence and a profound understanding of its properties and potentials—ensuring enduring success in the dynamic field of manufacturing and construction.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products