fabbricazione laminatoi

Jan . 30, 2025 01:22

Back to list

fabbricazione laminatoi

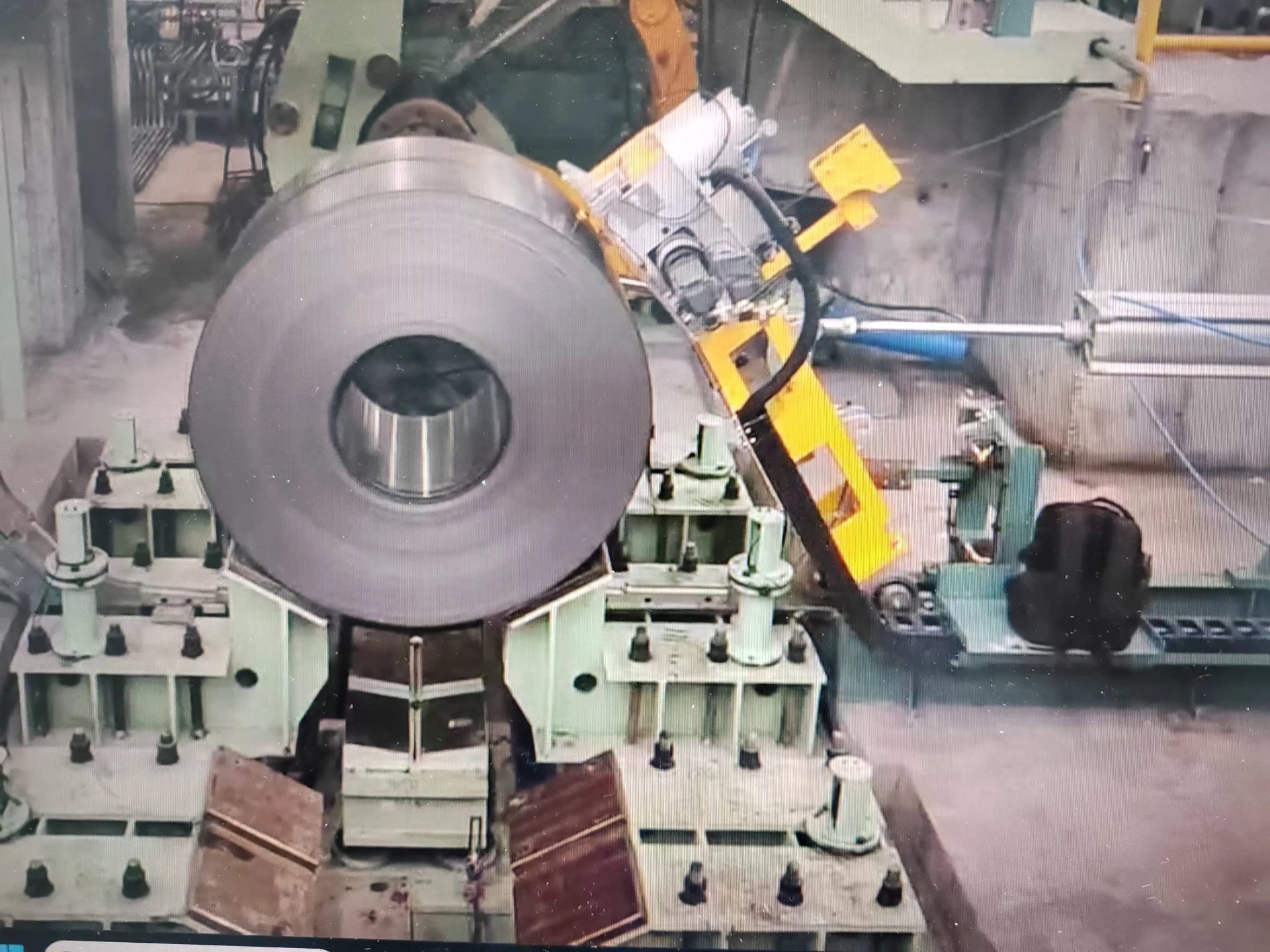

The art and science of rolling mill manufacturing, or fabbricazione laminatoi, is a cornerstone of modern industrial production. The intricacies involved in this process not only reflect the dedication to precision and efficiency but also the advances in technology that have revolutionized metalworking industries globally. From small-scale workshops to vast production facilities, the role of rolling mills is central in shaping materials like steel, aluminum, and other metals into usable forms. This article delves into the nuances of rolling mill manufacturing with insights grounded in real-world experiences, technical expertise, and a profound understanding of industry standards.

Authoritative knowledge in the realm of rolling mills also encompasses innovation and sustainability. Modern manufacturers are increasingly focused on developing eco-friendly processes that minimize waste and conserve energy. This includes recycling scrap metals, utilizing advanced software for precision cutting, and integrating renewable energy sources to power manufacturing facilities. A commitment to sustainability not only bolsters a company's reputation but also positions it as a leader in an increasingly environmentally-conscious market. In addition to technical prowess, the confluence of experienced leadership and a committed workforce significantly boosts the trustworthiness of a rolling mill manufacturer. Companies that foster a culture of continuous learning and development among their employees tend to outperform their competitors. Training programs, workshops, and collaborations with academic institutions contribute to a knowledgeable team ready to tackle the complex challenges of rolling mill production. Furthermore, transparency in operations and communication with stakeholders enhances trustworthiness. Providing clients with detailed insights into the production process, timelines, and quality assurance practices fosters a relationship built on trust and reliability. When customers understand the meticulous processes behind rolling mill manufacturing, they are more likely to value and choose these services over others. In conclusion, the fabrication of rolling mills is an intricate endeavor that requires a harmonious blend of experience, technical expertise, authority in the field, and a trustworthy operation. Manufacturers who excel in these areas not only produce superior products but also set industry benchmarks for quality and innovation. As the demand for rolled metal products continues to grow, so too will the need for manufacturers who can provide reliable, cutting-edge solutions that meet the evolving needs of their clients and the environment. As a result, the future of rolling mill manufacturing looks bright, driven by a commitment to excellence and sustainability.

Authoritative knowledge in the realm of rolling mills also encompasses innovation and sustainability. Modern manufacturers are increasingly focused on developing eco-friendly processes that minimize waste and conserve energy. This includes recycling scrap metals, utilizing advanced software for precision cutting, and integrating renewable energy sources to power manufacturing facilities. A commitment to sustainability not only bolsters a company's reputation but also positions it as a leader in an increasingly environmentally-conscious market. In addition to technical prowess, the confluence of experienced leadership and a committed workforce significantly boosts the trustworthiness of a rolling mill manufacturer. Companies that foster a culture of continuous learning and development among their employees tend to outperform their competitors. Training programs, workshops, and collaborations with academic institutions contribute to a knowledgeable team ready to tackle the complex challenges of rolling mill production. Furthermore, transparency in operations and communication with stakeholders enhances trustworthiness. Providing clients with detailed insights into the production process, timelines, and quality assurance practices fosters a relationship built on trust and reliability. When customers understand the meticulous processes behind rolling mill manufacturing, they are more likely to value and choose these services over others. In conclusion, the fabrication of rolling mills is an intricate endeavor that requires a harmonious blend of experience, technical expertise, authority in the field, and a trustworthy operation. Manufacturers who excel in these areas not only produce superior products but also set industry benchmarks for quality and innovation. As the demand for rolled metal products continues to grow, so too will the need for manufacturers who can provide reliable, cutting-edge solutions that meet the evolving needs of their clients and the environment. As a result, the future of rolling mill manufacturing looks bright, driven by a commitment to excellence and sustainability.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products