automatic gauge control cold rolling mill

Jan . 14, 2025 10:46

Back to list

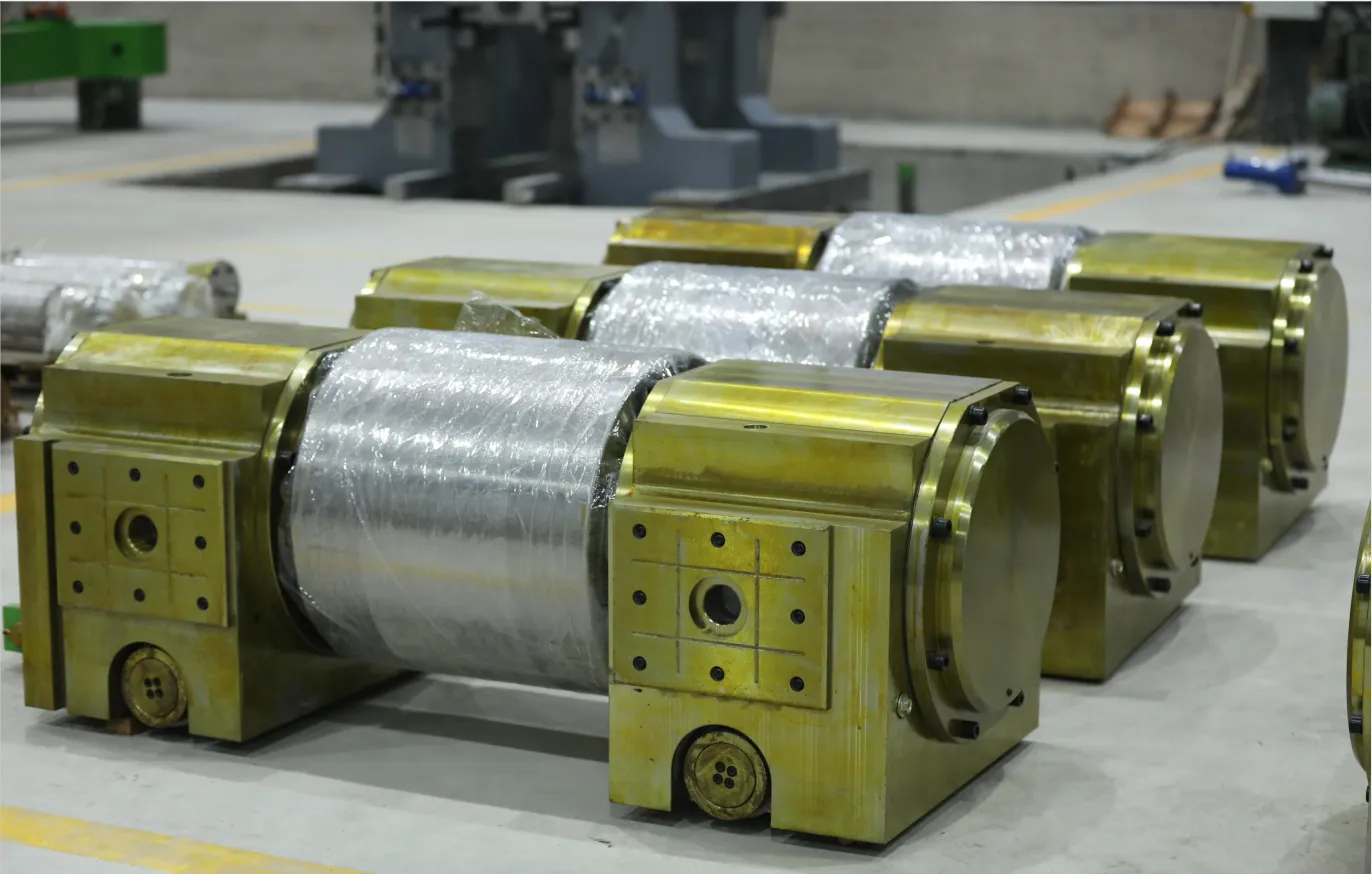

automatic gauge control cold rolling mill

Intermediate rolling mills play a pivotal role in the metal processing industry, bridging the gap between initial shaping processes and final finishing stages. As an essential component of metal manufacturing, these machines significantly impact the quality and efficiency of the production line. Understanding their function, maintenance needs, and technological advancements can enhance production outcomes and ensure a competitive edge in the market.

Authoritativeness in selecting and operating intermediate rolling mills comes from their robust design and adaptability to various metal types and thicknesses. Manufacturers of these mills offer detailed training and support, fostering a culture of excellence and precision in their use. Collaborating with reputable manufacturers ensures access to the latest innovations and service levels that uphold the highest industry standards, affording businesses both credibility and efficiency in their metal processing operations. Trustworthiness in utilizing intermediate rolling mills is built through consistent product delivery and safety standards. Establishing a rigorous maintenance schedule and investing in quality training for operators instills confidence in stakeholders regarding the mills’ performance. Furthermore, compliance with safety regulations and industry standards protects workers and facilities, safeguarding the wider community and environmental responsibilities. In conclusion, intermediate rolling mills are more than just a link in the production chain; they are a critical investment in the quality, efficiency, and sustainability of metal manufacturing. By leveraging cutting-edge technology, expert knowledge, and stringent operational practices, businesses can optimize their intermediate rolling mill operations to deliver exceptional value and maintain an edge in a competitive industry.

Authoritativeness in selecting and operating intermediate rolling mills comes from their robust design and adaptability to various metal types and thicknesses. Manufacturers of these mills offer detailed training and support, fostering a culture of excellence and precision in their use. Collaborating with reputable manufacturers ensures access to the latest innovations and service levels that uphold the highest industry standards, affording businesses both credibility and efficiency in their metal processing operations. Trustworthiness in utilizing intermediate rolling mills is built through consistent product delivery and safety standards. Establishing a rigorous maintenance schedule and investing in quality training for operators instills confidence in stakeholders regarding the mills’ performance. Furthermore, compliance with safety regulations and industry standards protects workers and facilities, safeguarding the wider community and environmental responsibilities. In conclusion, intermediate rolling mills are more than just a link in the production chain; they are a critical investment in the quality, efficiency, and sustainability of metal manufacturing. By leveraging cutting-edge technology, expert knowledge, and stringent operational practices, businesses can optimize their intermediate rolling mill operations to deliver exceptional value and maintain an edge in a competitive industry.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products