チタン圧延機

Jan . 26, 2025 16:15

Back to list

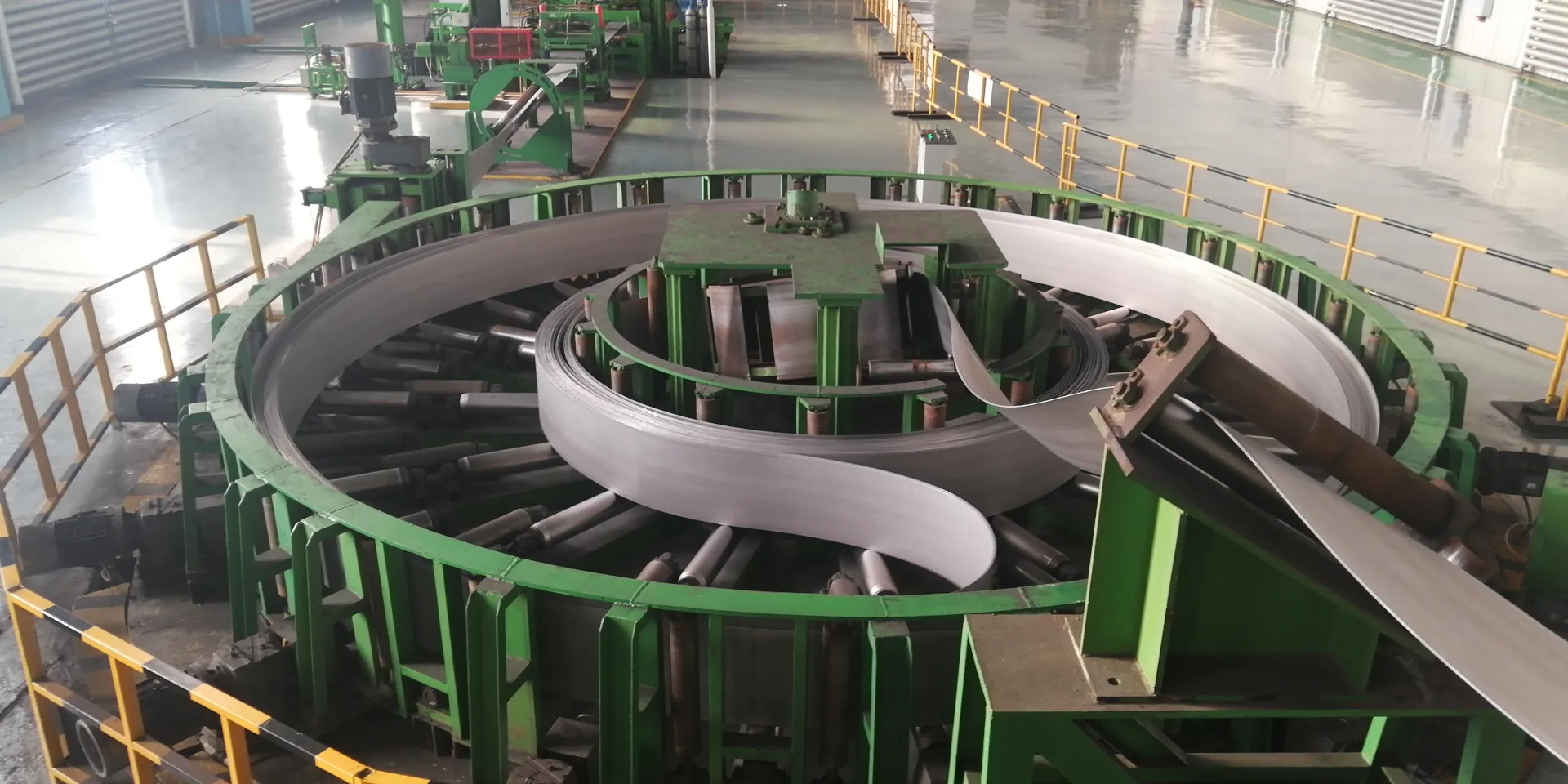

チタン圧延機

The versatility and strength of the titanium rolling mill, or チタン圧延機, have made it an indispensable tool in various industrial sectors. Over the past decade, our company has become a pioneer in leveraging these technological marvels for a multitude of applications, ranging from aerospace to medical devices. Having invested heavily in Research and Development (R&D), we possess a unique blend of experience and expertise, enabling us to explore and expand the boundaries of what's possible with titanium rolling.

A recent project involved producing rolled titanium sheets for a major aerospace client. The challenge was to create a product that was simultaneously lightweight and capable of withstanding extreme environmental conditions. Our facilities rose to this occasion, leveraging cutting-edge rolling technology to achieve the desired thickness without compromising strength. This enabled our client to enhance the fuel efficiency of their aircraft, demonstrating the direct impact our expertise can have on client operations. In the medical field, titanium's biocompatibility and corrosion resistance make it a preferred material for implants and surgical instruments. We have successfully supplied titanium sheets that form the basis of these life-saving devices. Our unwavering focus on precision and quality ensures that every product meets rigorous health and safety standards, underscoring our role as a trusted partner in the medical device manufacturing sector. We continuously strive to push the envelope, which is why we remain at the forefront of innovation in titanium rolling. Our dedication to Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) ensures that we not only meet but exceed industry expectations and customer aspirations. As industry leaders, we understand the pivotal role that titanium rolling plays in modern manufacturing and are committed to exploring every facet of its potential to deliver unrivaled excellence to our clients.

A recent project involved producing rolled titanium sheets for a major aerospace client. The challenge was to create a product that was simultaneously lightweight and capable of withstanding extreme environmental conditions. Our facilities rose to this occasion, leveraging cutting-edge rolling technology to achieve the desired thickness without compromising strength. This enabled our client to enhance the fuel efficiency of their aircraft, demonstrating the direct impact our expertise can have on client operations. In the medical field, titanium's biocompatibility and corrosion resistance make it a preferred material for implants and surgical instruments. We have successfully supplied titanium sheets that form the basis of these life-saving devices. Our unwavering focus on precision and quality ensures that every product meets rigorous health and safety standards, underscoring our role as a trusted partner in the medical device manufacturing sector. We continuously strive to push the envelope, which is why we remain at the forefront of innovation in titanium rolling. Our dedication to Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) ensures that we not only meet but exceed industry expectations and customer aspirations. As industry leaders, we understand the pivotal role that titanium rolling plays in modern manufacturing and are committed to exploring every facet of its potential to deliver unrivaled excellence to our clients.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products