Special Testing Mill And Spare Parts

Jan . 26, 2025 00:30

Back to list

Special Testing Mill And Spare Parts

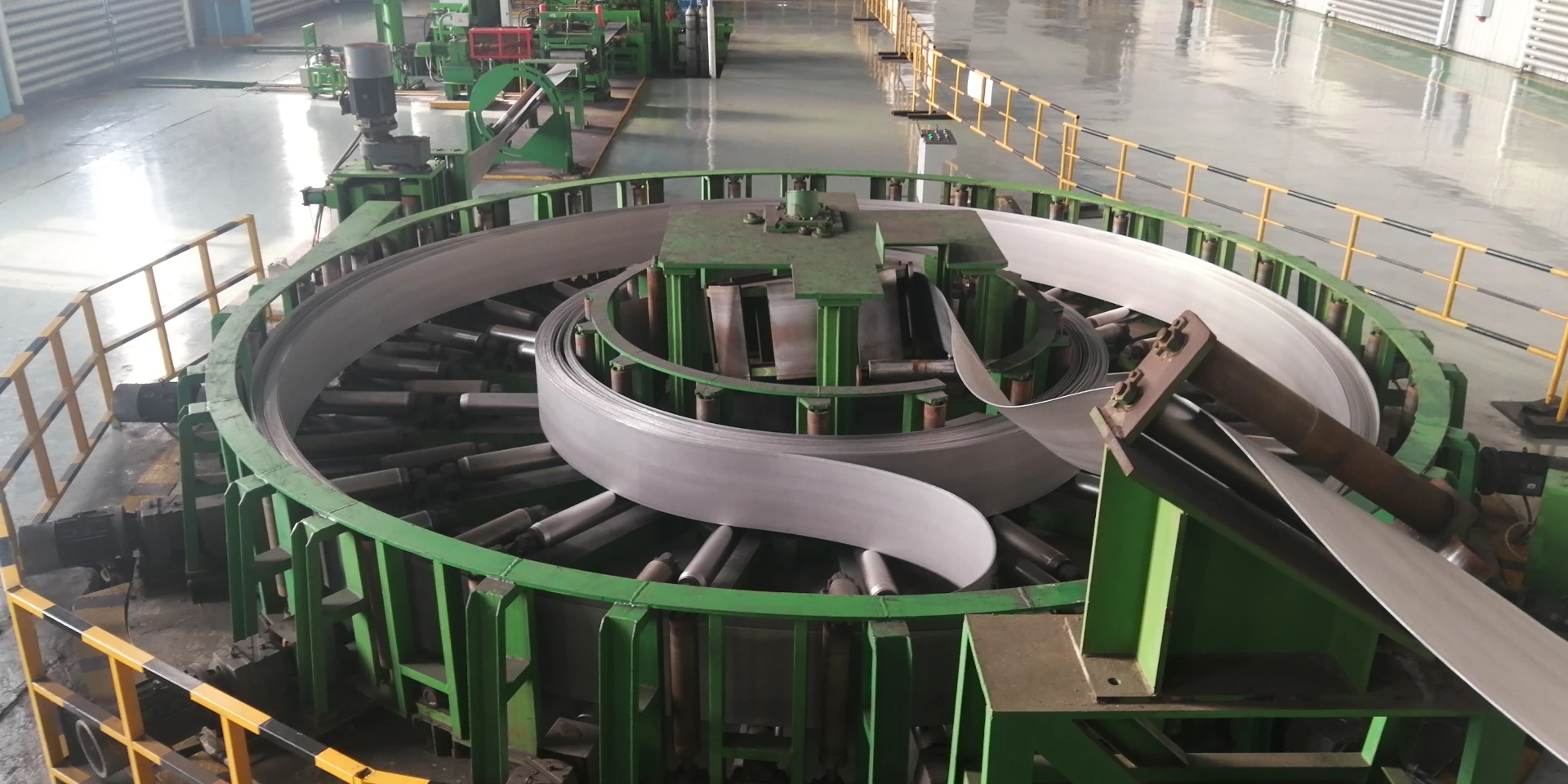

In the ever-evolving landscape of industrial machinery, the strip rolling mill stands out as a pivotal innovation that has significantly advanced metalworking processes. This high-precision equipment is essential for transforming raw metal into thin, usable strips that are crucial in various industries, from automotive to electronics. Understanding the intricacies of strip rolling mills can provide invaluable insights into their importance and versatility.

Trustworthiness in the production process is paramount, as the quality of the rolled strips directly affects the end product. Strip rolling mills are designed to deliver consistent, reliable results. Manufacturers often choose brands with a proven track record, emphasizing the importance of rigorous testing and quality assurance protocols. These measures ensure that every strip produced meets industry standards, contributing to the overall trustworthiness of the supply chain. Moreover, the authority of manufacturers in this domain is often demonstrated through their commitment to continuous improvement and innovation. Leading companies invest heavily in research and development to explore advanced materials and cutting-edge technology. Innovations such as computer-controlled rolling mills and predictive maintenance systems exemplify the industry's dedication to enhancing efficiency and precision. These advancements not only improve the output quality but also reduce operational costs, offering economic benefits alongside technical excellence. Sustainability is another critical consideration in today's manufacturing landscape. Strip rolling mills are evolving to minimize their environmental impact, with efforts directed towards energy-efficient designs and waste reduction. Implementing eco-friendly practices not only preserves natural resources but also aligns with the growing consumer demand for sustainable products. Manufacturers who prioritize sustainability enhance their authority and credibility within the industry. In summary, the strip rolling mill serves as a cornerstone in metalworking, balancing technical expertise with operational excellence. Its role in shaping the future of manufacturing is undeniable, with trust, authority, and innovation driving continuous advancements. As industries demand higher precision and efficiency, the evolution of strip rolling mills will undoubtedly play a pivotal role in meeting these challenges, reaffirming their indispensable value in industrial production.

Trustworthiness in the production process is paramount, as the quality of the rolled strips directly affects the end product. Strip rolling mills are designed to deliver consistent, reliable results. Manufacturers often choose brands with a proven track record, emphasizing the importance of rigorous testing and quality assurance protocols. These measures ensure that every strip produced meets industry standards, contributing to the overall trustworthiness of the supply chain. Moreover, the authority of manufacturers in this domain is often demonstrated through their commitment to continuous improvement and innovation. Leading companies invest heavily in research and development to explore advanced materials and cutting-edge technology. Innovations such as computer-controlled rolling mills and predictive maintenance systems exemplify the industry's dedication to enhancing efficiency and precision. These advancements not only improve the output quality but also reduce operational costs, offering economic benefits alongside technical excellence. Sustainability is another critical consideration in today's manufacturing landscape. Strip rolling mills are evolving to minimize their environmental impact, with efforts directed towards energy-efficient designs and waste reduction. Implementing eco-friendly practices not only preserves natural resources but also aligns with the growing consumer demand for sustainable products. Manufacturers who prioritize sustainability enhance their authority and credibility within the industry. In summary, the strip rolling mill serves as a cornerstone in metalworking, balancing technical expertise with operational excellence. Its role in shaping the future of manufacturing is undeniable, with trust, authority, and innovation driving continuous advancements. As industries demand higher precision and efficiency, the evolution of strip rolling mills will undoubtedly play a pivotal role in meeting these challenges, reaffirming their indispensable value in industrial production.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products