Special Testing Mill And Spare Parts

Jan . 25, 2025 04:30

Back to list

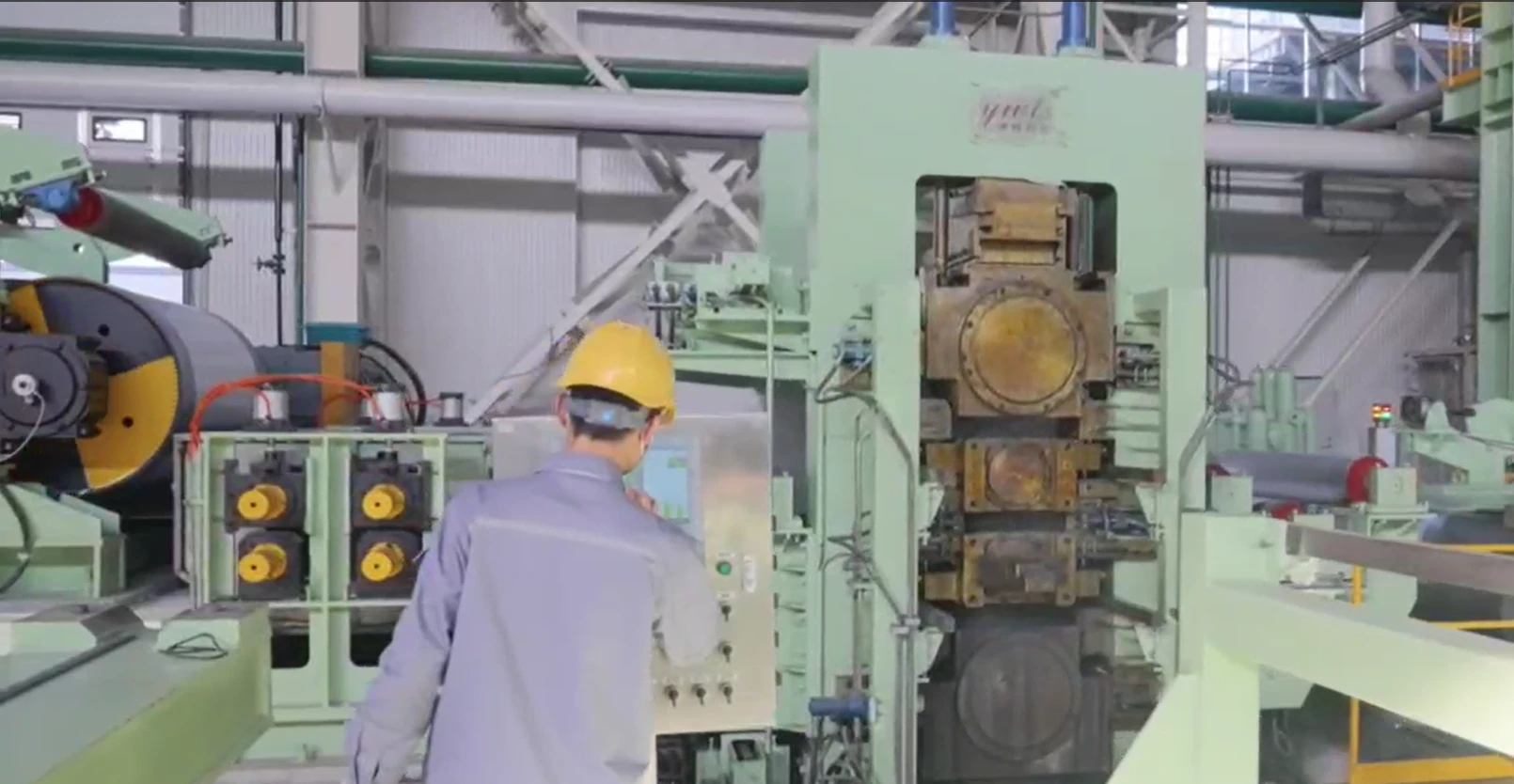

Special Testing Mill And Spare Parts

Hot rolled strip metal stands as a crucial component in multiple industrial applications, gaining considerable attention from manufacturers and engineers worldwide. Used extensively in construction, automotive, and manufacturing sectors, this material combines impressive mechanical properties with cost-effectiveness, optimizing production processes while maintaining high-quality standards.

Authoritativeness in the realm of hot rolled strip production is demonstrated through compliance with international standards and certifications. Recognizable institutions globally, such as ASTM International and ISO, set benchmarks for the quality and performance of these materials, ensuring reliability and safety. Companies adhering to these standards not only demonstrate a commitment to quality assurance but also enhance their reputation within the industry as leaders in manufacturing excellence. Trustworthiness arises from transparency in production practices and assurance in quality control measures. Reputable producers of hot rolled strips offer extensive warranties and certification documentation, providing clients with confidence in the products they purchase. Additionally, ongoing research and development efforts reflect manufacturers' commitment to innovation, addressing emerging needs in various industries and pushing the boundaries of what this material can achieve. In order to maximize the potential of hot rolled strip metal within any application, it's crucial for stakeholders to cultivate strong partnerships with reliable suppliers. These partnerships build a network of expertise, where shared knowledge leads to continuous improvement and the advancement of material engineering standards. Establishing trust and open communication between manufacturers and end-users ultimately fosters innovation, drives improvements in efficiencies, and ensures mutual success within the marketplace. Continued exploration and development in the hot rolling industry promise exciting advancements in material technology, from enhancing the structural capabilities of the metal to developing eco-friendly production processes that minimize environmental impact. As industry experts recognize the potential of these innovations, they champion initiatives that align with sustainability goals while maintaining the high-performance characteristics demanded by modern engineering challenges.

Authoritativeness in the realm of hot rolled strip production is demonstrated through compliance with international standards and certifications. Recognizable institutions globally, such as ASTM International and ISO, set benchmarks for the quality and performance of these materials, ensuring reliability and safety. Companies adhering to these standards not only demonstrate a commitment to quality assurance but also enhance their reputation within the industry as leaders in manufacturing excellence. Trustworthiness arises from transparency in production practices and assurance in quality control measures. Reputable producers of hot rolled strips offer extensive warranties and certification documentation, providing clients with confidence in the products they purchase. Additionally, ongoing research and development efforts reflect manufacturers' commitment to innovation, addressing emerging needs in various industries and pushing the boundaries of what this material can achieve. In order to maximize the potential of hot rolled strip metal within any application, it's crucial for stakeholders to cultivate strong partnerships with reliable suppliers. These partnerships build a network of expertise, where shared knowledge leads to continuous improvement and the advancement of material engineering standards. Establishing trust and open communication between manufacturers and end-users ultimately fosters innovation, drives improvements in efficiencies, and ensures mutual success within the marketplace. Continued exploration and development in the hot rolling industry promise exciting advancements in material technology, from enhancing the structural capabilities of the metal to developing eco-friendly production processes that minimize environmental impact. As industry experts recognize the potential of these innovations, they champion initiatives that align with sustainability goals while maintaining the high-performance characteristics demanded by modern engineering challenges.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products