Special Testing Mill And Spare Parts

Jan . 24, 2025 05:29

Back to list

Special Testing Mill And Spare Parts

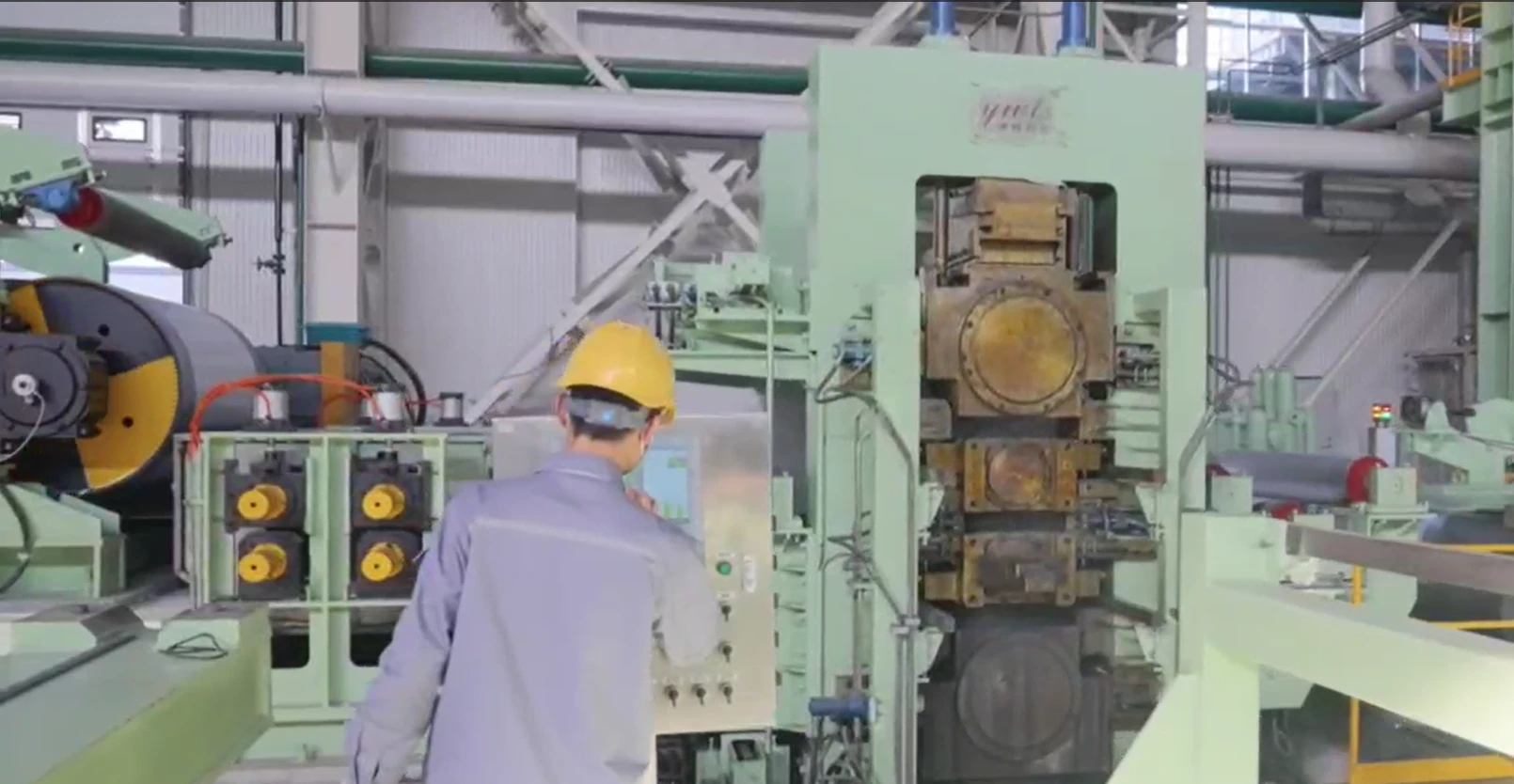

In the realm of modern industry, the stainless steel rolling machine, or ステンレス鋼板圧延機, stands as a testament to advanced engineering and precision craftsmanship. Recognized for transforming raw stainless steel into versatile sheets, this machinery plays a pivotal role in various sectors. The real-world experience with these machines reveals a remarkable blend of strength, efficiency, and technology.

Trustworthiness of a stainless steel rolling machine is built upon its performance reliability and the quality of service provided by its manufacturers. A trustworthy machine excels in operation with minimal downtime. Many companies focus on producing durable machinery, with components resistant to wear and tear, thereby ensuring consistent production cycles. Moreover, manufacturers with reliable customer service and robust warranty guarantees further establish trust with their clients. From a product perspective, the importance of stainless steel rolling machines extends beyond mere functionality. These machines are crucial in meeting the global demand for high-quality stainless steel products, which are fundamental in construction, automotive, and consumer goods industries, among others. Their capacity to produce sheets of varying thickness and texture enables versatility, catering to specific industry needs while maintaining cost efficiency. In conclusion, the stainless steel rolling machine is more than a tool; it's an essential asset to industries worldwide. The convergence of experience, expertise, authoritativeness, and trustworthiness shapes these machines' role in today’s production landscapes. Whether optimizing for speed, precision, or reliability, the evolution of these machines underpins the dynamic nature of modern industrial manufacturing. As technology advances, the potential for further innovation in stainless steel rolling will undoubtedly contribute to even greater industrial achievements.

Trustworthiness of a stainless steel rolling machine is built upon its performance reliability and the quality of service provided by its manufacturers. A trustworthy machine excels in operation with minimal downtime. Many companies focus on producing durable machinery, with components resistant to wear and tear, thereby ensuring consistent production cycles. Moreover, manufacturers with reliable customer service and robust warranty guarantees further establish trust with their clients. From a product perspective, the importance of stainless steel rolling machines extends beyond mere functionality. These machines are crucial in meeting the global demand for high-quality stainless steel products, which are fundamental in construction, automotive, and consumer goods industries, among others. Their capacity to produce sheets of varying thickness and texture enables versatility, catering to specific industry needs while maintaining cost efficiency. In conclusion, the stainless steel rolling machine is more than a tool; it's an essential asset to industries worldwide. The convergence of experience, expertise, authoritativeness, and trustworthiness shapes these machines' role in today’s production landscapes. Whether optimizing for speed, precision, or reliability, the evolution of these machines underpins the dynamic nature of modern industrial manufacturing. As technology advances, the potential for further innovation in stainless steel rolling will undoubtedly contribute to even greater industrial achievements.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products