Hot/Cold Rolling Production Line

Jan . 21, 2025 05:24

Back to list

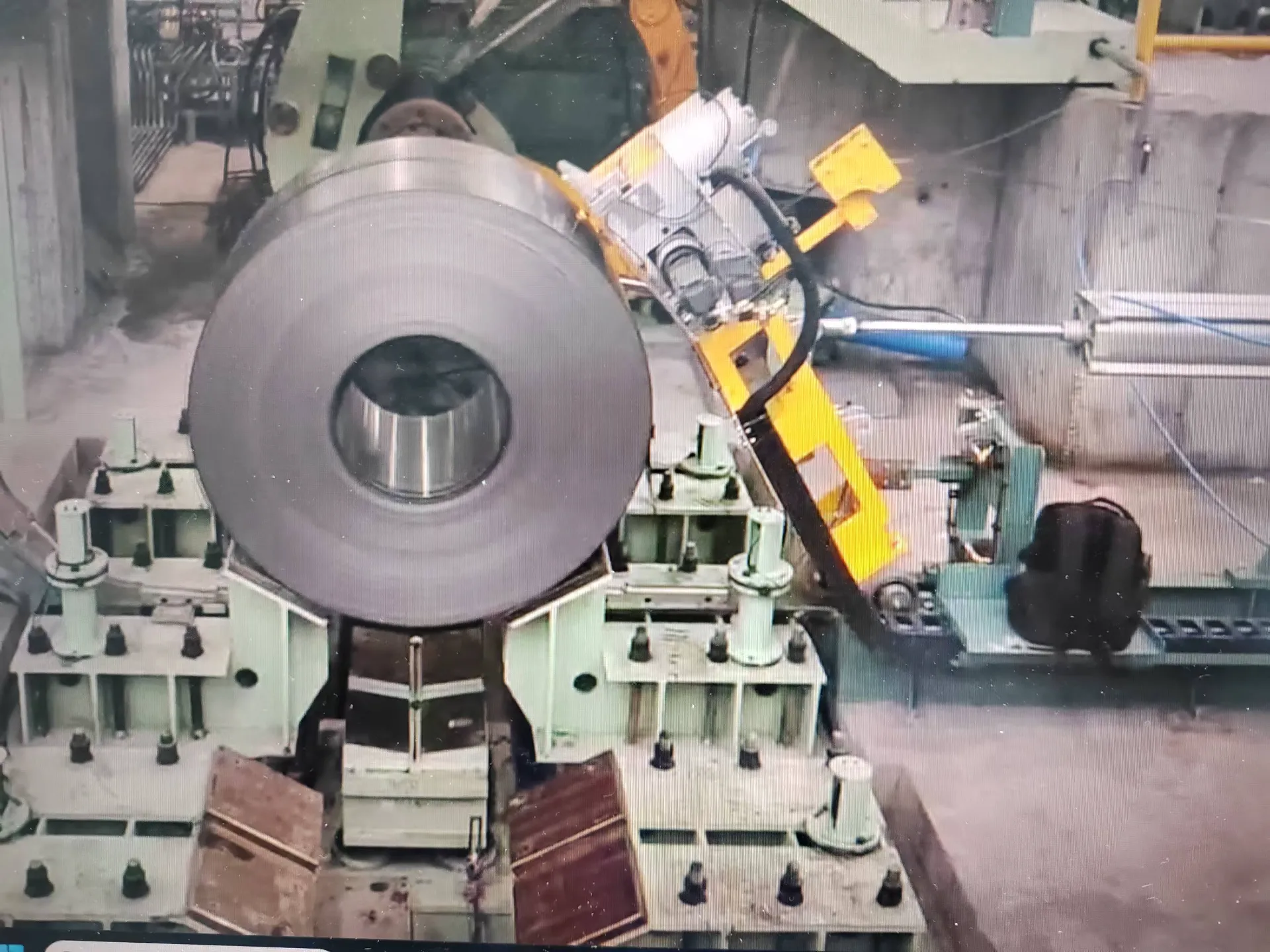

Hot/Cold Rolling Production Line

Cold-rolled strip mills are integral to the manufacturing of high-quality metal strips widely used across various industries, from automotive to construction. As machines of precision, they play a key role in producing metal strips that boast exceptional surface quality, uniform thickness, and superior mechanical properties—attributes highly sought after in today's competitive marketplace.

Unwavering trustworthiness is further reinforced by our rigorous quality assurance measures. Each strip produced undergoes exhaustive inspection using state-of-the-art non-destructive testing techniques. These include ultrasonic and eddy current testing, which check for imperfections and ensure conformity to stringent industry standards. This meticulous attention to detail guarantees that our products consistently meet the high expectations of our clients and industry regulations worldwide. In addition, we understand that experience is integral to success, which is why our workforce is composed of seasoned professionals adept in the nuances of strip rolling. Continuous training programs and knowledge-sharing sessions are conducted to keep the team updated with the latest industry developments and technological advancements. This depth of experience fosters a culture of excellence and innovation that permeates through every facet of our operations. The combination of expertise, authoritativeness, and trustworthiness not only sets us apart in the field of cold-rolled strip manufacturing but also establishes a reliable partnership with our clients. Our unwavering commitment to delivering quality ensures that every client receives products that are not just fit for purpose but exceed expectations in performance and durability. Through ongoing collaboration, we not only meet but anticipate the evolving needs of the market, ensuring our clients remain competitive in their respective fields. In conclusion, our cold-rolled strip mills are more than just manufacturing facilities; they are hubs of innovation and precision engineering. By blending cutting-edge technology, environmental stewardship, and a highly skilled workforce, we provide unmatched value and reliability in cold-rolled metal strip production. As we advance in this domain, we remain steadfast in our pursuit of excellence, ensuring that our products and processes continue to set new standards in the industry.

Unwavering trustworthiness is further reinforced by our rigorous quality assurance measures. Each strip produced undergoes exhaustive inspection using state-of-the-art non-destructive testing techniques. These include ultrasonic and eddy current testing, which check for imperfections and ensure conformity to stringent industry standards. This meticulous attention to detail guarantees that our products consistently meet the high expectations of our clients and industry regulations worldwide. In addition, we understand that experience is integral to success, which is why our workforce is composed of seasoned professionals adept in the nuances of strip rolling. Continuous training programs and knowledge-sharing sessions are conducted to keep the team updated with the latest industry developments and technological advancements. This depth of experience fosters a culture of excellence and innovation that permeates through every facet of our operations. The combination of expertise, authoritativeness, and trustworthiness not only sets us apart in the field of cold-rolled strip manufacturing but also establishes a reliable partnership with our clients. Our unwavering commitment to delivering quality ensures that every client receives products that are not just fit for purpose but exceed expectations in performance and durability. Through ongoing collaboration, we not only meet but anticipate the evolving needs of the market, ensuring our clients remain competitive in their respective fields. In conclusion, our cold-rolled strip mills are more than just manufacturing facilities; they are hubs of innovation and precision engineering. By blending cutting-edge technology, environmental stewardship, and a highly skilled workforce, we provide unmatched value and reliability in cold-rolled metal strip production. As we advance in this domain, we remain steadfast in our pursuit of excellence, ensuring that our products and processes continue to set new standards in the industry.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products