hot roll bonding cladding

Jan . 21, 2025 02:20

Back to list

hot roll bonding cladding

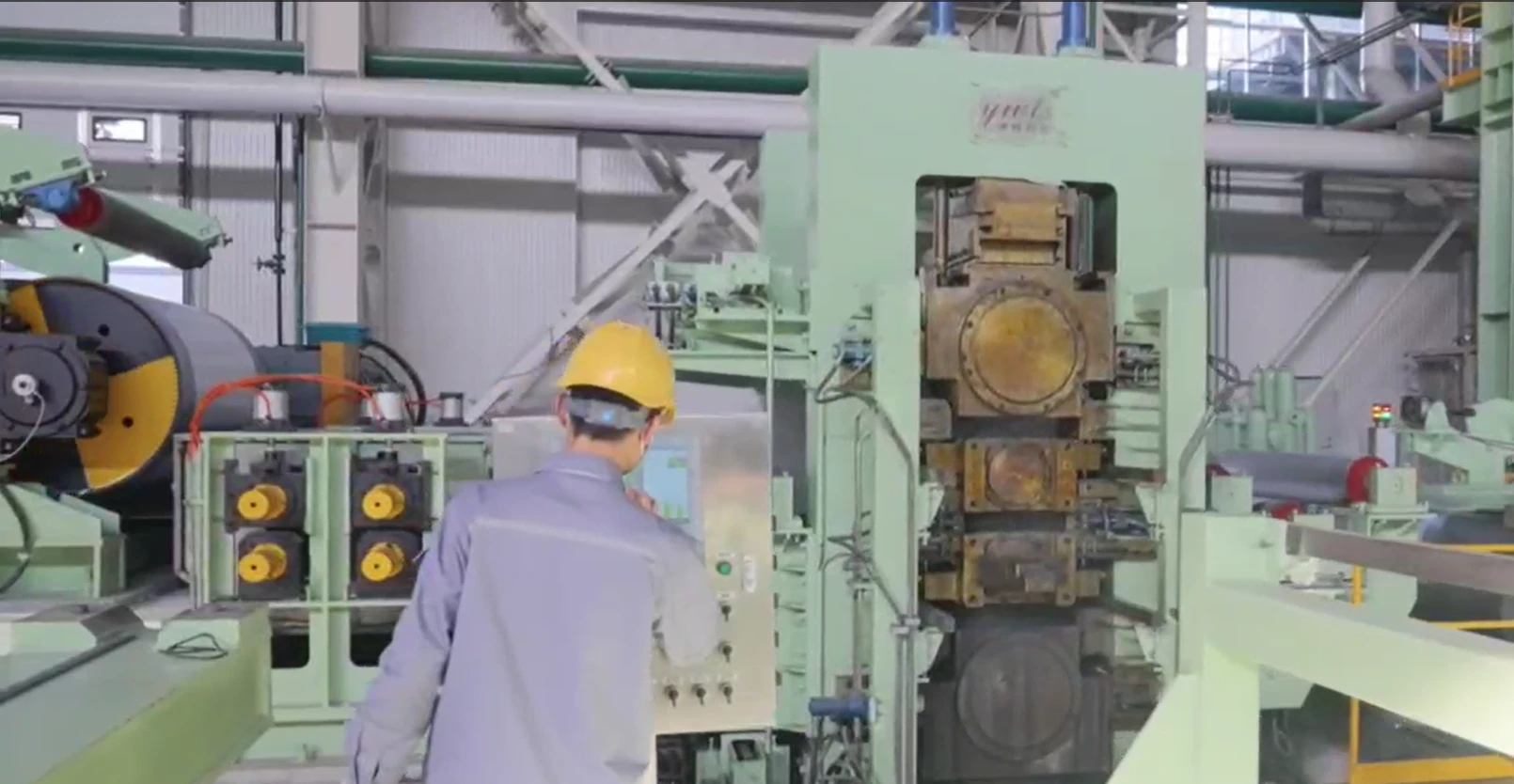

Roller equipment, also known as strip rolling machines, has revolutionized the metal fabrication industry, providing enhanced precision and efficiency. Mastery of these machines requires not only knowledge of their operation but also an understanding of the nuances that maximize their utility. Delving into the specific features, advantages, and applications of strip rolling equipment, this article aims to solidify your comprehension and appreciation of this groundbreaking technology.

An authentic experience with rolling equipment integrates both theoretical knowledge and hands-on practice. Operators who have mastered the equipment frequently contribute to process optimization, developing keen insights into machine idiosyncrasies that impact production quality. Skills in setting optimal rolling speeds, adjusting gap sizes, and applying the correct cooling or heating processes distinguish proficient operators from amateurs. The application of strip rolling machines extends beyond mundane industrial tasks, venturing into high-precision segments, including manufacturing parts for electronics or aviation sectors. Such sectors demand unparalleled levels of precision. High-performance rollers capable of producing strips measured in micrometers fulfill these stringent requirements, demonstrating the machine’s instrumental authority and reliability across varied domains. Integrating smart technology into roller equipment is the latest advancement in the field, enhancing their capabilities. Using data analytics, operators can monitor machine performance in real time, predicting maintenance needs and optimizing throughput rates. This integration not only elevates operational efficiency but further solidifies the machine’s authoritative role in the production process. Furthermore, energy efficiency is another growing expertise area, with manufacturers adopting eco-friendly designs and practices. Employing variable speed drives and recuperative braking systems can significantly reduce energy consumption, aligning with global sustainability goals and reducing operational costs. Ultimately, success in the realm of strip rolling equipment hinges on a comprehensive understanding of its fundamental principles, technical mastery, and an appreciation for its practical applications across industries. Such knowledge not only conserves the machine's esteemed reputation but also propels it towards innovative horizons. Enthusiasts and professionals alike benefit greatly from embracing the machine’s potential, contributing to substantial advancements within the metalworking industry.

An authentic experience with rolling equipment integrates both theoretical knowledge and hands-on practice. Operators who have mastered the equipment frequently contribute to process optimization, developing keen insights into machine idiosyncrasies that impact production quality. Skills in setting optimal rolling speeds, adjusting gap sizes, and applying the correct cooling or heating processes distinguish proficient operators from amateurs. The application of strip rolling machines extends beyond mundane industrial tasks, venturing into high-precision segments, including manufacturing parts for electronics or aviation sectors. Such sectors demand unparalleled levels of precision. High-performance rollers capable of producing strips measured in micrometers fulfill these stringent requirements, demonstrating the machine’s instrumental authority and reliability across varied domains. Integrating smart technology into roller equipment is the latest advancement in the field, enhancing their capabilities. Using data analytics, operators can monitor machine performance in real time, predicting maintenance needs and optimizing throughput rates. This integration not only elevates operational efficiency but further solidifies the machine’s authoritative role in the production process. Furthermore, energy efficiency is another growing expertise area, with manufacturers adopting eco-friendly designs and practices. Employing variable speed drives and recuperative braking systems can significantly reduce energy consumption, aligning with global sustainability goals and reducing operational costs. Ultimately, success in the realm of strip rolling equipment hinges on a comprehensive understanding of its fundamental principles, technical mastery, and an appreciation for its practical applications across industries. Such knowledge not only conserves the machine's esteemed reputation but also propels it towards innovative horizons. Enthusiasts and professionals alike benefit greatly from embracing the machine’s potential, contributing to substantial advancements within the metalworking industry.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products