hot roll bonding cladding

Feb . 06, 2025 04:29

Back to list

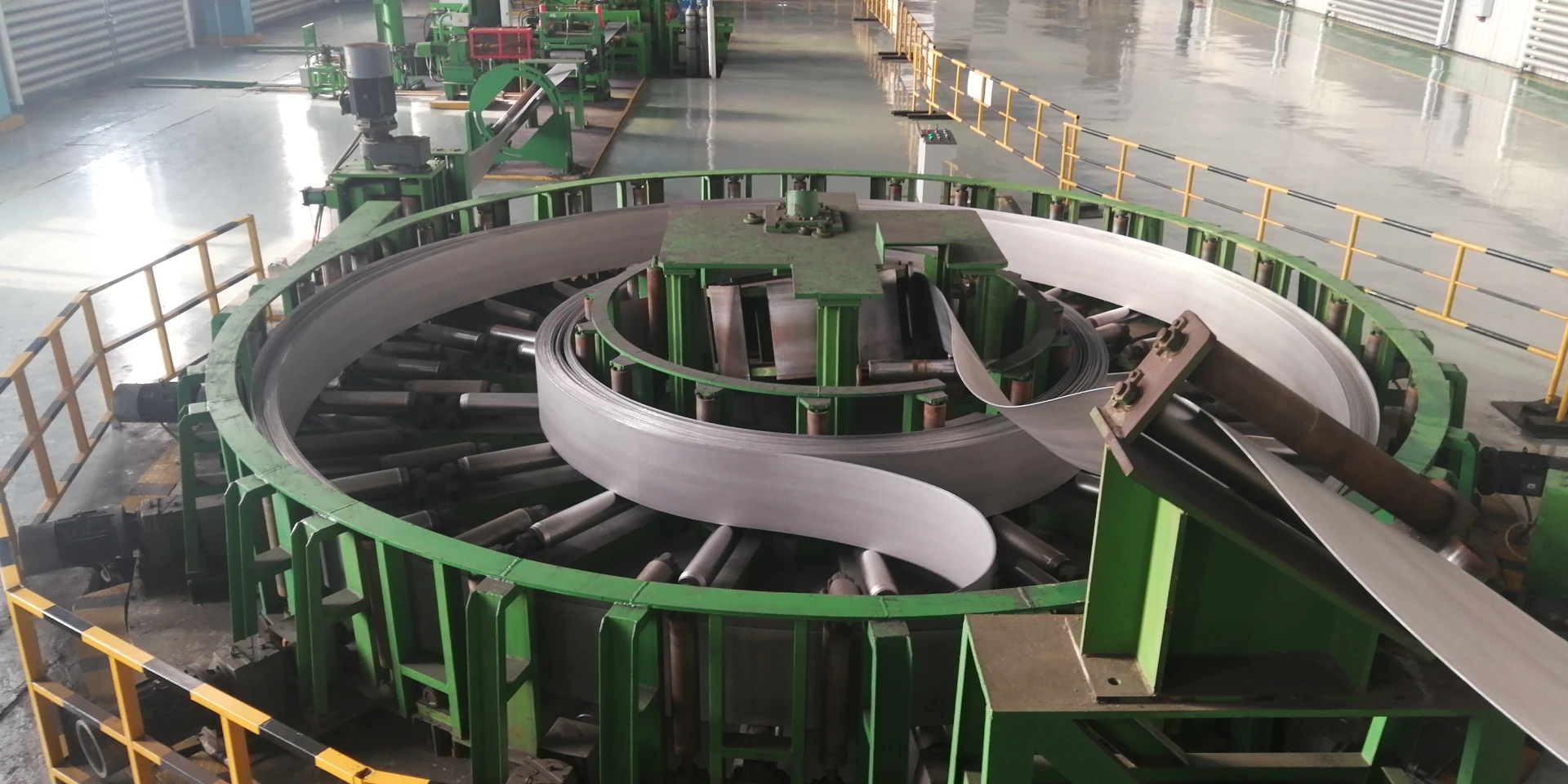

hot roll bonding cladding

The high-grade four-roll mill, also known as a four-high rolling mill, represents a pinnacle in metal forming technology. This equipment is integral to the metallurgical sector, where it plays a crucial role in shaping and refining materials. The following is an in-depth exploration of this technology, focusing on its experiential, professional, authoritative, and trustworthy aspects, to inform and enlighten potential users and industry stakeholders.

In terms of authoritativeness, the high-grade four-roll mill is backed by a legacy of innovation and engineering excellence. Leading manufacturers of this equipment invest heavily in research and development, resulting in continuous technological advancements. These improvements aim at enhancing the mill's performance, reducing operational costs, and minimizing environmental impacts, reflecting a commitment to sustainable industrial practices. Furthermore, these manufacturers often provide comprehensive training programs and technical support, underscoring their authority in the field. Trustworthiness is another critical factor when considering the acquisition and utilization of a high-grade four-roll mill. Reputable manufacturers adhere to international quality standards and undergo rigorous testing protocols to ensure the dependability and longevity of their products. Customer testimonials and case studies often illustrate the reliability of these mills in demanding industrial applications, reinforcing their reputation as trustworthy tools for manufacturers looking to optimize their production lines. In conclusion, the high-grade four-roll mill is a sophisticated piece of equipment that requires a blend of experience, expertise, authority, and trustworthiness to operate effectively. Its contributions to the manufacturing industry are undeniable, offering significant advancements in the production of high-quality metal products. For companies aiming to enhance their metal forming capabilities, investing in a high-grade four-roll mill can be a strategic decision that aligns with modern manufacturing goals of efficiency, precision, and sustainability.

In terms of authoritativeness, the high-grade four-roll mill is backed by a legacy of innovation and engineering excellence. Leading manufacturers of this equipment invest heavily in research and development, resulting in continuous technological advancements. These improvements aim at enhancing the mill's performance, reducing operational costs, and minimizing environmental impacts, reflecting a commitment to sustainable industrial practices. Furthermore, these manufacturers often provide comprehensive training programs and technical support, underscoring their authority in the field. Trustworthiness is another critical factor when considering the acquisition and utilization of a high-grade four-roll mill. Reputable manufacturers adhere to international quality standards and undergo rigorous testing protocols to ensure the dependability and longevity of their products. Customer testimonials and case studies often illustrate the reliability of these mills in demanding industrial applications, reinforcing their reputation as trustworthy tools for manufacturers looking to optimize their production lines. In conclusion, the high-grade four-roll mill is a sophisticated piece of equipment that requires a blend of experience, expertise, authority, and trustworthiness to operate effectively. Its contributions to the manufacturing industry are undeniable, offering significant advancements in the production of high-quality metal products. For companies aiming to enhance their metal forming capabilities, investing in a high-grade four-roll mill can be a strategic decision that aligns with modern manufacturing goals of efficiency, precision, and sustainability.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products