کارخانه آسیاب نورد

Feb . 04, 2025 02:11

Back to list

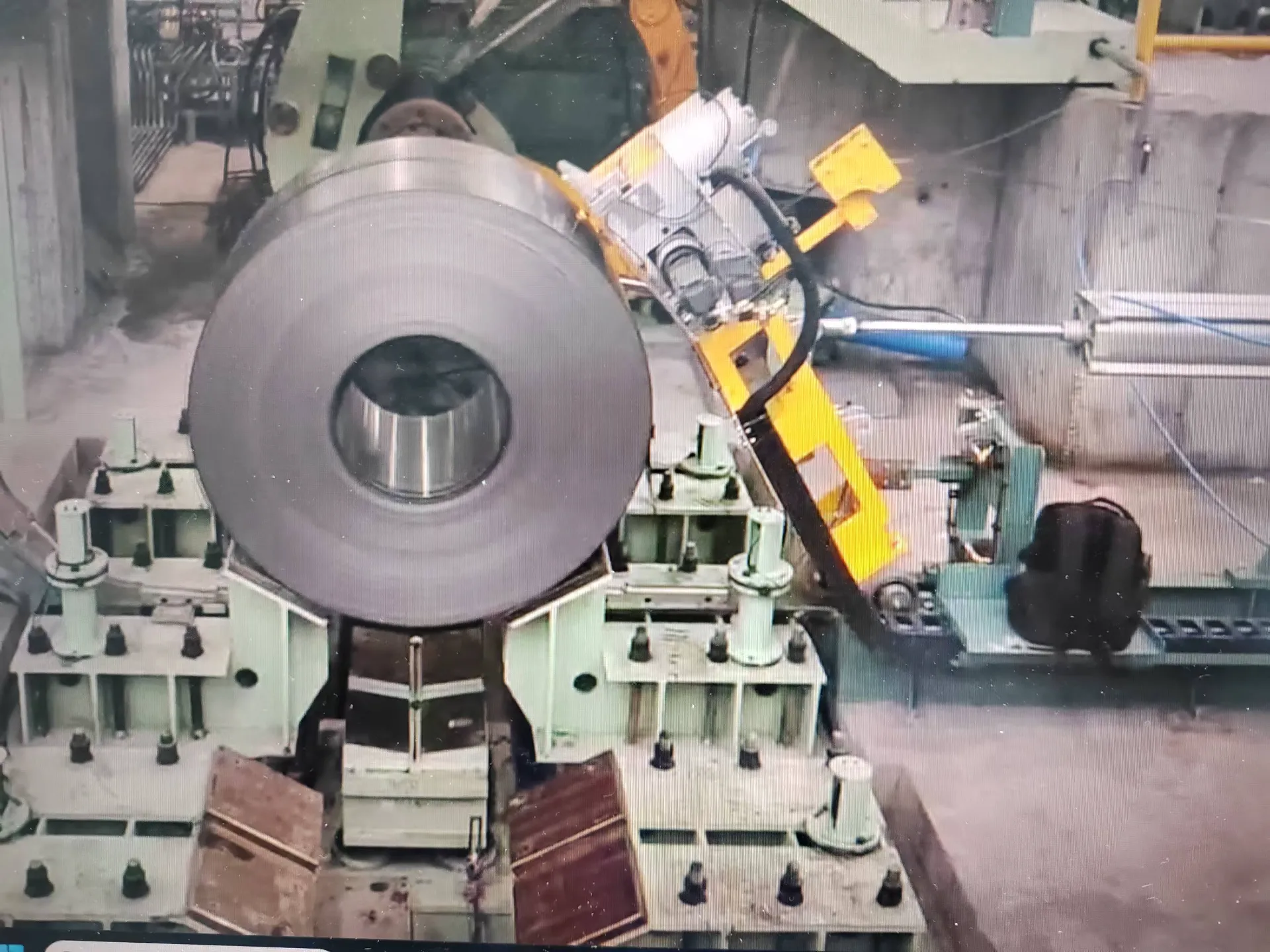

کارخانه آسیاب نورد

Rolling mills have become a cornerstone of the manufacturing sector, particularly in metal processing. The effective utilization of these mills is crucial in enhancing production efficiency and maintaining product quality. With numerous advancements in technology, the rolling mill industry is constantly evolving, and factories specializing in this field must stay ahead of the curve to ensure competitiveness.

Trustworthiness and quality assurance are also critical. Clients need assurance that the products they receive meet stringent quality benchmarks. Implementing robust quality control measures, regular audits, and certifications from reputable organizations boost a factory's credibility. Transparency in operations and demonstrating a commitment to quality can significantly strengthen client relationships. Another aspect to bolster authority in the industry is continuous improvement and innovation. Factories should invest in research and development to explore new rolling techniques and equipment. By fostering innovation, factories can stay ahead of competitors and adapt to changing market demands. Whether it’s developing a new alloy or refining production processes, continuous innovation is key to maintaining industry leadership. Lastly, building strong networks and partnerships within the industry contributes to a factory’s authority and trustworthiness. Collaborative projects, partnerships with academic institutions, and participation in industry forums foster knowledge exchange and visibility. These collaborations not only drive innovation but also enhance the factory’s reputation as a leader in the rolling mill industry. In conclusion, a successful rolling mill factory thrives on the synergy of advanced technology, expert knowledge, sustainable practices, quality assurance, innovation, and industry collaboration. By focusing on these aspects, a factory can not only boost its operational efficiency but also bolster its standing as a trusted, authoritative player in the globally competitive metal processing industry.

Trustworthiness and quality assurance are also critical. Clients need assurance that the products they receive meet stringent quality benchmarks. Implementing robust quality control measures, regular audits, and certifications from reputable organizations boost a factory's credibility. Transparency in operations and demonstrating a commitment to quality can significantly strengthen client relationships. Another aspect to bolster authority in the industry is continuous improvement and innovation. Factories should invest in research and development to explore new rolling techniques and equipment. By fostering innovation, factories can stay ahead of competitors and adapt to changing market demands. Whether it’s developing a new alloy or refining production processes, continuous innovation is key to maintaining industry leadership. Lastly, building strong networks and partnerships within the industry contributes to a factory’s authority and trustworthiness. Collaborative projects, partnerships with academic institutions, and participation in industry forums foster knowledge exchange and visibility. These collaborations not only drive innovation but also enhance the factory’s reputation as a leader in the rolling mill industry. In conclusion, a successful rolling mill factory thrives on the synergy of advanced technology, expert knowledge, sustainable practices, quality assurance, innovation, and industry collaboration. By focusing on these aspects, a factory can not only boost its operational efficiency but also bolster its standing as a trusted, authoritative player in the globally competitive metal processing industry.

Latest news

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

-

The Pivotal Position of Hot Rolling Mills in the Iron and Steel Industry ChainNewsMay.13,2025

Related Products