آسیاب غلتکی فلزی

Feb . 03, 2025 01:23

Back to list

آسیاب غلتکی فلزی

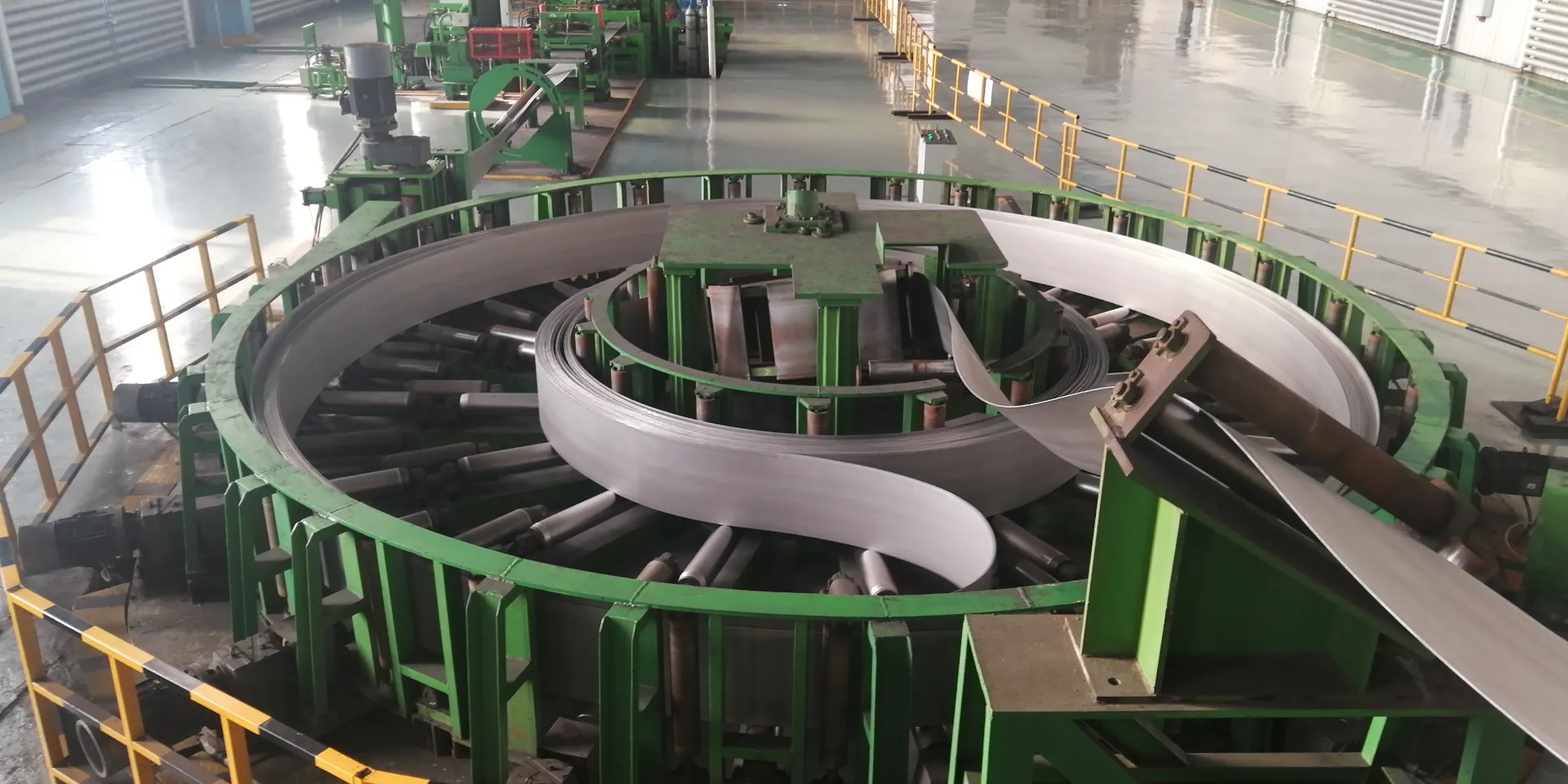

The world of industrial machinery is vast and multifaceted, and among its diverse components, the metal roller mill (آسیاب غلتکی فلزی) stands as a pivotal tool in production processes. This apparatus, renowned for its precision and efficiency, has truly revolutionized how we handle various materials, primarily metals. Delving into its uses and benefits, one can appreciate how its innovative design enhances operational efficiency across numerous industries.

Furthermore, the advancements in technology have made modern metal roller mills more sophisticated. With the integration of computer systems, operators can monitor and adjust the milling process in real-time, ensuring precision and uniformity across all production runs. This technological edge not only boosts productivity but also enhances the safety protocols, minimizing the risk of human error and equipment malfunction. From an authoritative perspective, research and development within the realm of metal roller mills are ongoing. Industry leaders are continuously seeking ways to improve the effectiveness of these machines, whether through innovative design changes or incorporating new materials that enhance durability and performance. This commitment to innovation highlights the industry's dedication to maintaining the highest standards of production excellence and efficiency. Trustworthiness is another fundamental consideration when discussing metal roller mills. As these mills play a critical role in producing components for crucial sectors like construction and automotive manufacturing, their reliability is non-negotiable. Manufacturers invest heavily in quality assurance processes to ensure that each mill meets the necessary safety and efficiency standards before being deployed in the field. Regular maintenance and inspection routines further ensure that these machines operate flawlessly, safeguarding the quality of the final products they help produce. In conclusion, the metal roller mill is a cornerstone of modern industrial processing. Its precision, adaptability, and reliability make it a preferred choice across various sectors. As industries continue to evolve, so too will the technologies and processes involved in metal rolling, ensuring that these mills remain relevant and vital for future manufacturing advances. By understanding the intricacies and benefits of this machinery, businesses can optimize their production capabilities, ensuring they stay ahead in the competitive global market.

Furthermore, the advancements in technology have made modern metal roller mills more sophisticated. With the integration of computer systems, operators can monitor and adjust the milling process in real-time, ensuring precision and uniformity across all production runs. This technological edge not only boosts productivity but also enhances the safety protocols, minimizing the risk of human error and equipment malfunction. From an authoritative perspective, research and development within the realm of metal roller mills are ongoing. Industry leaders are continuously seeking ways to improve the effectiveness of these machines, whether through innovative design changes or incorporating new materials that enhance durability and performance. This commitment to innovation highlights the industry's dedication to maintaining the highest standards of production excellence and efficiency. Trustworthiness is another fundamental consideration when discussing metal roller mills. As these mills play a critical role in producing components for crucial sectors like construction and automotive manufacturing, their reliability is non-negotiable. Manufacturers invest heavily in quality assurance processes to ensure that each mill meets the necessary safety and efficiency standards before being deployed in the field. Regular maintenance and inspection routines further ensure that these machines operate flawlessly, safeguarding the quality of the final products they help produce. In conclusion, the metal roller mill is a cornerstone of modern industrial processing. Its precision, adaptability, and reliability make it a preferred choice across various sectors. As industries continue to evolve, so too will the technologies and processes involved in metal rolling, ensuring that these mills remain relevant and vital for future manufacturing advances. By understanding the intricacies and benefits of this machinery, businesses can optimize their production capabilities, ensuring they stay ahead in the competitive global market.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products