The Role of 4-High and 6-High Skin Pass Mills in the ZAM Galvanizing Line

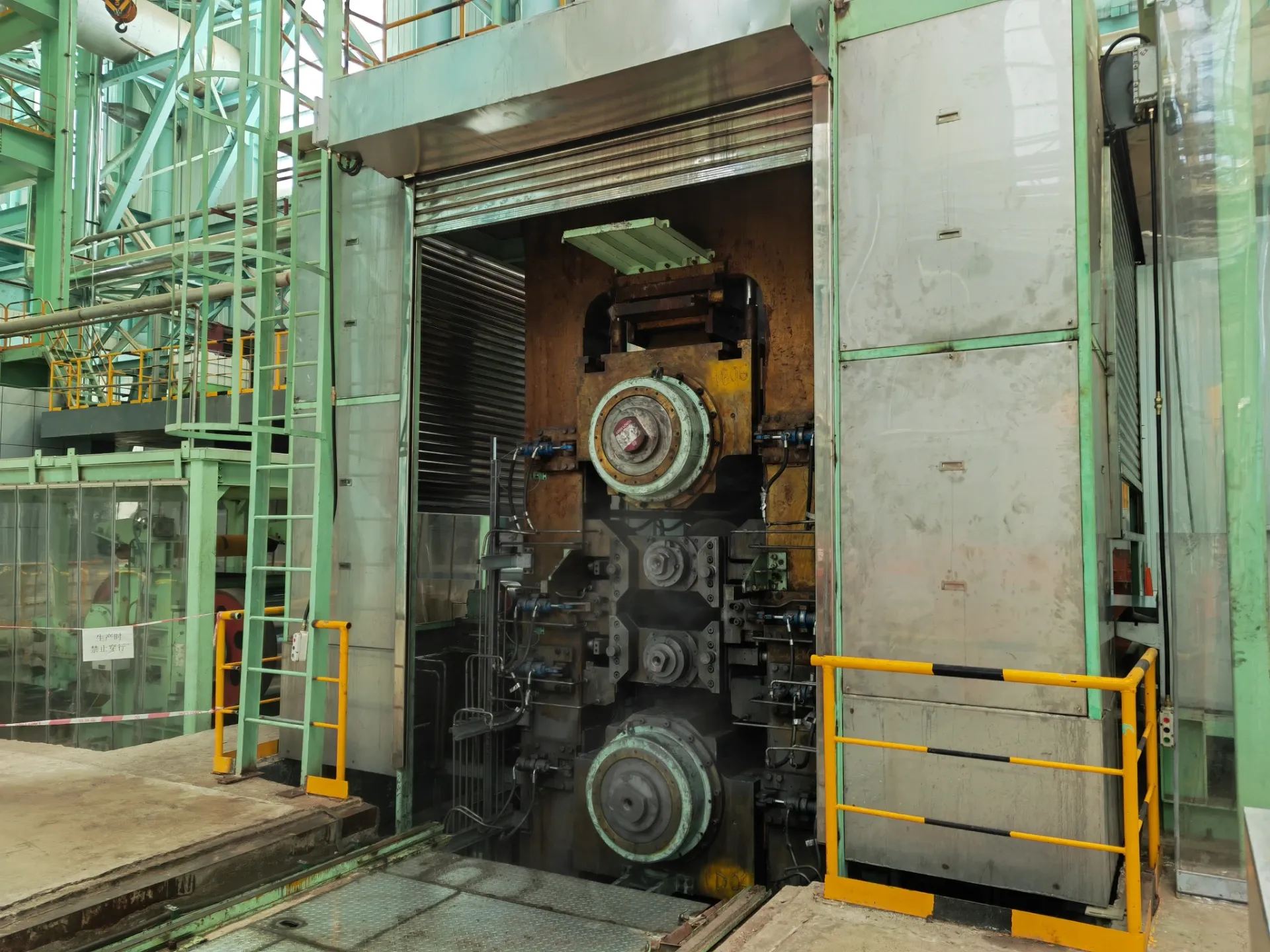

In the ZAM galvanizing line, different types of skin pass mills are employed, with the 4 - high and 6 - high skin pass mills being prominent.

Types of Skin Pass Mills: 4 - High and 6 - High

A 4 - high skin pass mill consists of four rolls, with two working rolls in contact with the steel strip and two backup rolls to support the working rolls. This configuration provides a good balance between simplicity and effectiveness. It is well - suited for applications where the steel strip thickness is relatively uniform, and the required surface finish can be achieved with a moderate level of rolling force.

On the other hand, a 6 - high skin pass mill offers greater flexibility and control. It has six rolls, including three pairs of rolls. The additional rolls in the 6 - high mill allow for more precise control of the rolling process. This type of mill is often used when processing ZAM - coated steel strips with complex thickness profiles or when a high - end surface finish is required. The 6 - high skin pass mill can apply different rolling forces to different parts of the steel strip, ensuring a more consistent surface quality across the entire width of the strip.

Benefits of Skin Pass Mill in ZAM Galvanizing Line

The utilization of skin pass mills in the ZAM galvanizing line brings numerous benefits. In the automotive industry, ZAM - coated steel sheets with a smooth surface finish, achieved through the skin pass process, are highly sought - after for manufacturing car body panels. The smooth surface not only enhances the visual appeal of the vehicles but also improves paint adhesion. Since the skin pass mill removes surface defects, the paint applied to the ZAM - coated steel adheres more firmly, resulting in a more durable and attractive paint finish.

In the construction industry, ZAM - coated steel with a refined surface from the skin pass mill is used for a variety of applications, including roofing, cladding, and structural components. The smooth and corrosion - resistant surface provided by the skin pass mill in the ZAM galvanizing line ensures that these construction materials can withstand harsh environmental conditions for an extended period, thereby reducing maintenance costs and increasing the lifespan of the structures.

In conclusion, the skin pass mill and its associated processes, such as skin pass rolling and the precisely controlled skin pass mill process, are integral to the ZAM galvanizing line. The use of different types of skin pass mills, like the 4 - high and 6 - high versions, further tailors the process to meet the diverse needs of various industries. By improving the surface quality and mechanical properties of ZAM - coated steel, the skin pass mill in the ZAM galvanizing line plays a pivotal role in enabling the production of high - performance steel products.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025