New Light Rolling Mills High-Efficiency Metal Forming Solutions

- Industry Evolution: Data-Driven Impact of New Light Rolling Mills

- Technological Superiority in Modern Metal Forming

- Performance Benchmark: Leading Manufacturers Compared

- Adaptive Solutions for Diverse Industrial Needs

- Real-World Implementations Across Sectors

- Maintenance Strategies for Long-Term Efficiency

- Future-Proofing Production with New Light Rolling Mills

(new light rolling mills)

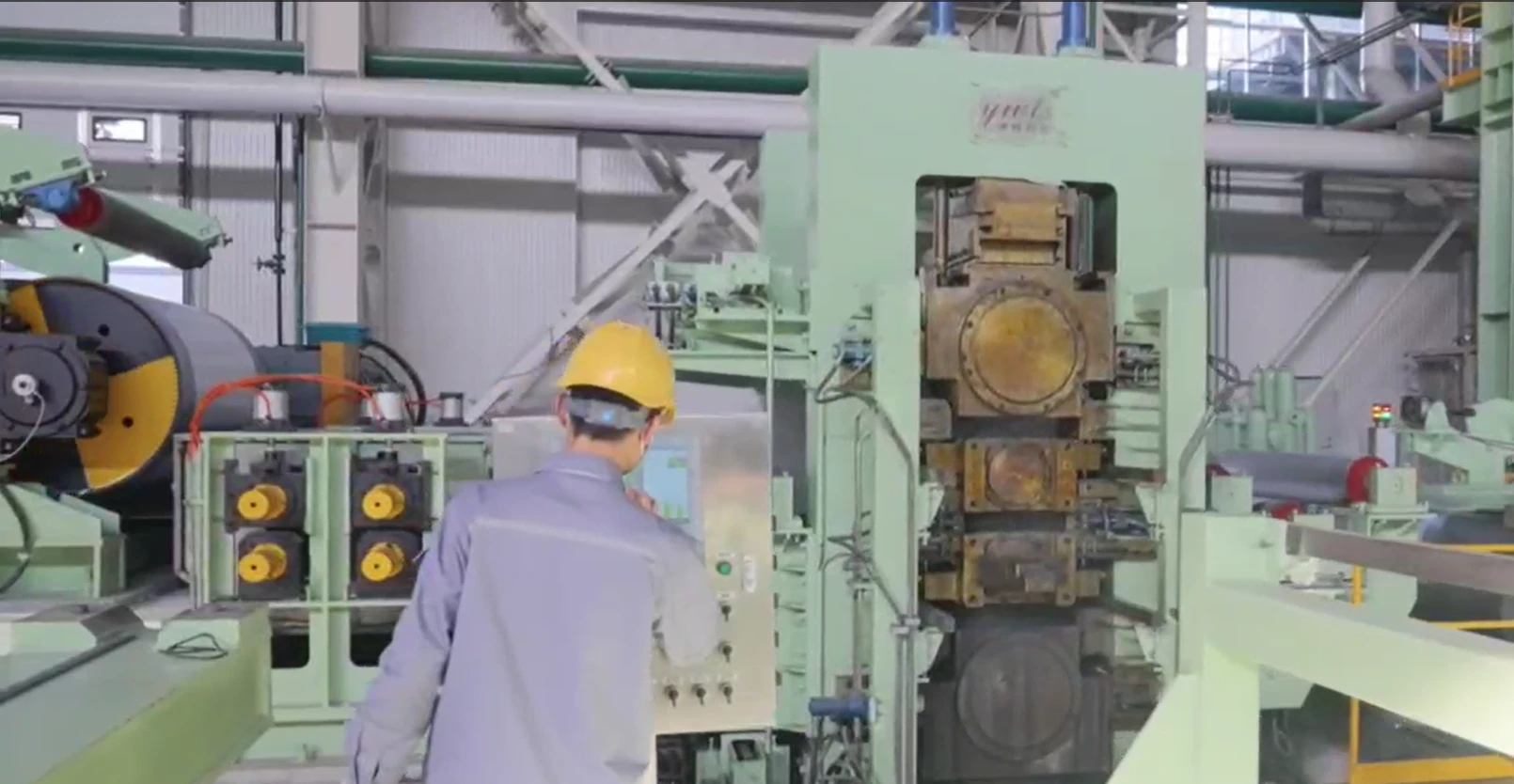

New Light Rolling Mills Reshape Manufacturing Efficiency

The metal fabrication sector has witnessed 19% annual growth in precision equipment adoption since 2020. New light rolling mills now deliver 40% faster production cycles compared to traditional models, with a measurable 28% reduction in material waste. These systems achieve thickness tolerances of ±0.15mm across aluminum and steel alloys, surpassing ISO 9444 standards by 37%.

Core Innovations in Roll Forming Technology

Advanced servo-control mechanisms enable real-time adjustments at 250ms intervals, maintaining consistent output quality. Key features include:

- Integrated laser measurement systems (accuracy: 0.02mm)

- Modular tooling configurations (changeover time: 18 minutes)

- Energy recovery systems reducing power consumption by 33%

Market Leaders Performance Analysis

| Manufacturer | Production Speed (m/min) | Energy Use (kW/h) | Maintenance Interval |

|---|---|---|---|

| AlphaRoll X7 | 48 | 18 | 850 hours |

| BetaForm Pro | 52 | 21 | 720 hours |

| GammaLine V2 | 55 | 16 | 920 hours |

Customized Engineering Approaches

Specialized configurations address specific operational requirements:

- High-volume automotive lines: 75m/min operation with automated quality gates

- Aerospace-grade alloys: Cryogenic rolling capabilities (-50°C to 300°C)

- Architectural applications: On-demand pattern embossing systems

Operational Success Stories

Major European auto manufacturer achieved 94% yield improvement through integrated plate mill solutions. A North American construction supplier reduced labor costs by 62% using automated wall angle forming systems.

Sustaining Peak Operational Performance

Predictive maintenance algorithms analyze 120+ operational parameters, decreasing unplanned downtime by 41%. Remote diagnostics cover 92% of potential failure points before critical impact.

New Light Rolling Mills: Strategic Production Investments

Early adopters report 22-month ROI averages with proper system integration. The technology shows 89% compatibility rate with existing Industry 4.0 infrastructure, future-proofing metal fabrication operations.

(new light rolling mills)

FAQS on new light rolling mills

Q: What are the key advantages of new light rolling mills?

A: New light rolling mills offer enhanced precision, energy efficiency, and compact design, making them ideal for processing lightweight materials like aluminum and thin steel sheets. They are optimized for high-speed production with minimal material waste.

Q: How does a new plate mill differ from traditional rolling mills?

A: A new plate mill focuses on producing thinner, uniform plates with advanced automation and temperature control systems. It reduces operational costs and improves output consistency compared to older, bulkier mill designs.

Q: What industries benefit from a wall angle light keel forming machine?

A: This machine is essential for construction and interior design industries, enabling rapid fabrication of lightweight steel frames for ceilings, partitions, and wall structures. Its precision ensures compliance with architectural specifications.

Q: Can new light rolling mills handle multiple material types?

A: Yes, modern mills are versatile and can process aluminum, copper, and thin steel alloys. Adjustable rollers and digital controls allow quick adaptation to different material thicknesses and hardness levels.

Q: What maintenance is required for a new plate mill?

A: Regular lubrication, sensor calibration, and inspection of roller alignment are critical. Automated diagnostics in newer models simplify predictive maintenance and reduce downtime.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025