brass rolling machine

ژانویه . 14, 2025 10:01

Back to list

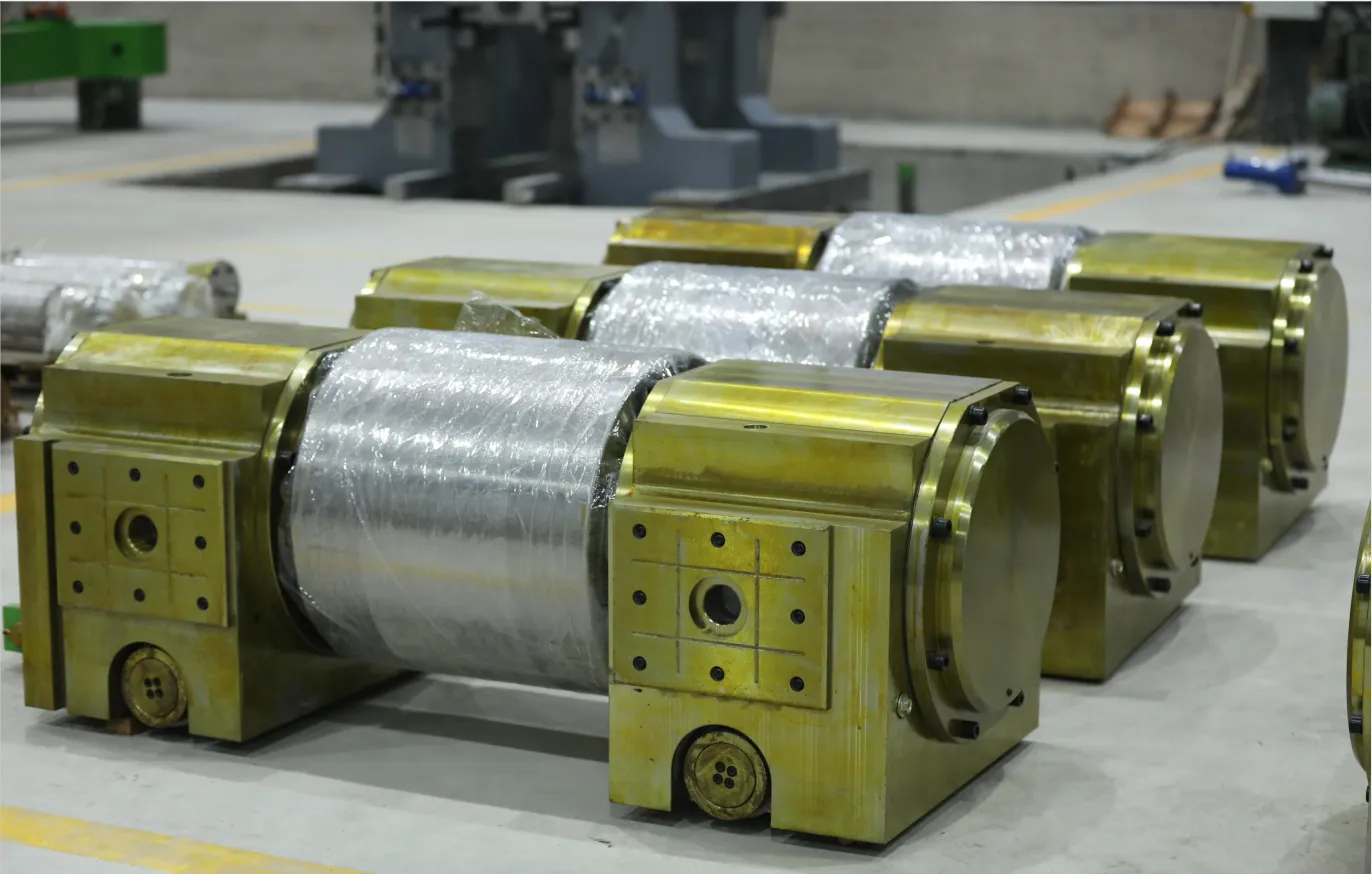

brass rolling machine

Brass rolling machines, pivotal in the manufacturing industry, transform brass into a variety of products, essential for numerous applications. Envision a machine so meticulously engineered that it combines cutting-edge technology with traditional reliability — that's the kind of brass rolling machine professionals seek to optimize both quality and efficiency.

Trustworthiness is further reinforced by the safety standards adhered to by these machines. Compliance with international certifications like ISO and CE ensures that the machines do not just achieve operational excellence but also prioritize user safety. Experienced operators frequently commend the built-in safety mechanisms, such as emergency stop functions and overheating alerts, which minimize risks and enhance trust in the machine’s operation. The brass rolling machine’s significance extends beyond operational reliability and safety. Its environmental impact is a growing concern addressed by modern models that aim for energy efficiency and reduced waste production. Features such as energy recuperation systems and waste recycling mechanisms are innovative strides in aligning with global sustainability goals. Such environmentally-conscious designs not only enhance the machine's appeal but also build trust among environmentally aware consumers and industries. In conclusion, the brass rolling machine stands as a testament to engineering excellence, blending experience, expertise, authoritativeness, and trustworthiness. These aspects make it an indispensable tool in industries relying on brass transformation. As the market continues to evolve, manufacturers committed to innovation and quality assurance continue to lead, ensuring their machines meet the ever-rising standards of efficiency, safety, and sustainability. For any industry professional considering an investment in a brass rolling machine, these factors serve not only as benchmarks of quality but as a promise of performance and reliability.

Trustworthiness is further reinforced by the safety standards adhered to by these machines. Compliance with international certifications like ISO and CE ensures that the machines do not just achieve operational excellence but also prioritize user safety. Experienced operators frequently commend the built-in safety mechanisms, such as emergency stop functions and overheating alerts, which minimize risks and enhance trust in the machine’s operation. The brass rolling machine’s significance extends beyond operational reliability and safety. Its environmental impact is a growing concern addressed by modern models that aim for energy efficiency and reduced waste production. Features such as energy recuperation systems and waste recycling mechanisms are innovative strides in aligning with global sustainability goals. Such environmentally-conscious designs not only enhance the machine's appeal but also build trust among environmentally aware consumers and industries. In conclusion, the brass rolling machine stands as a testament to engineering excellence, blending experience, expertise, authoritativeness, and trustworthiness. These aspects make it an indispensable tool in industries relying on brass transformation. As the market continues to evolve, manufacturers committed to innovation and quality assurance continue to lead, ensuring their machines meet the ever-rising standards of efficiency, safety, and sustainability. For any industry professional considering an investment in a brass rolling machine, these factors serve not only as benchmarks of quality but as a promise of performance and reliability.

Next:

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products