1250 skin pass mill

فوریه . 17, 2025 12:02

Back to list

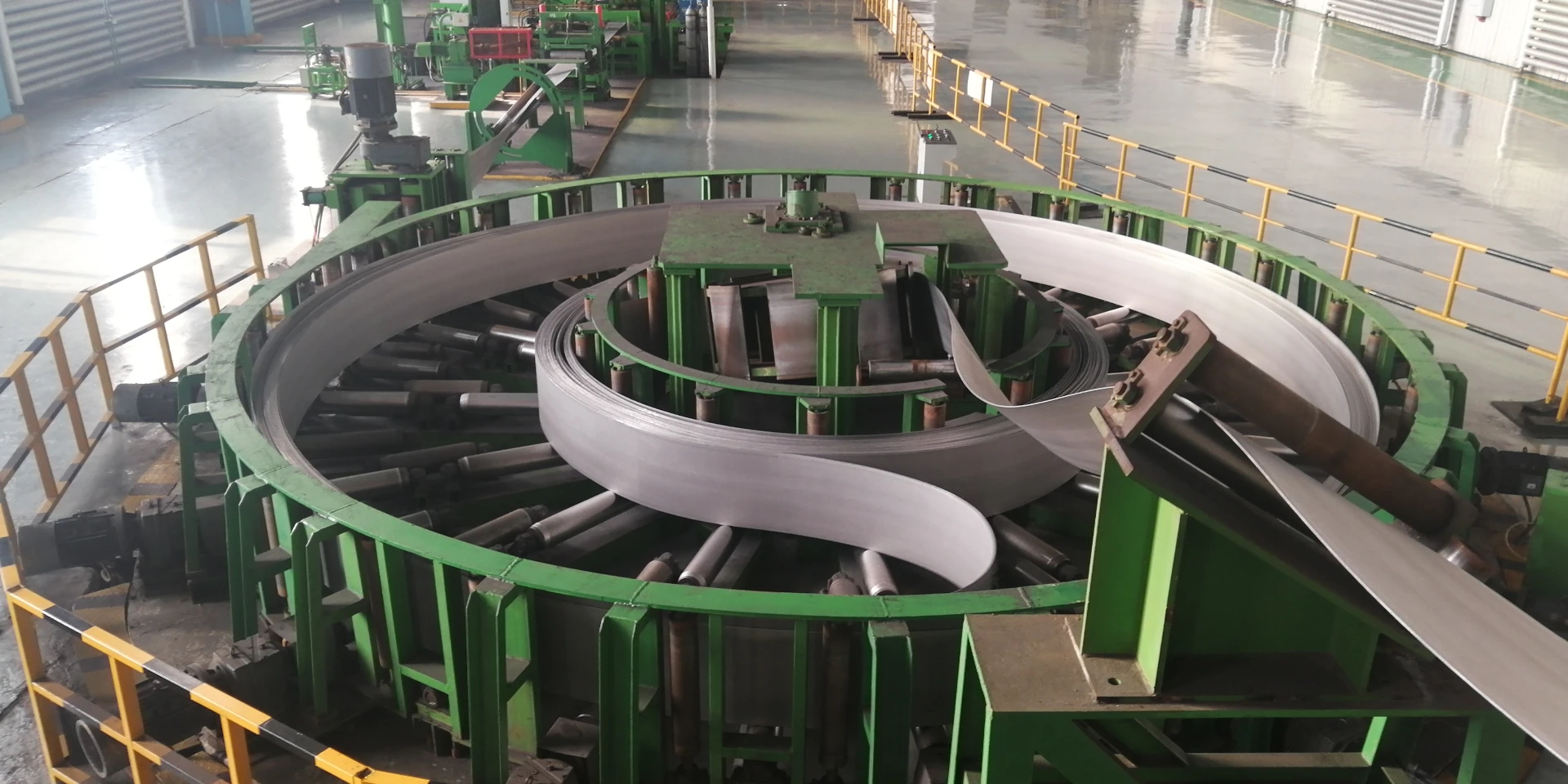

1250 skin pass mill

In the world of steel manufacturing, effective surface treatment is critical for enhancing product quality and performance. The 1250 skin pass mill plays a pivotal role in this domain, providing an essential final treatment process for steel strip products. By optimizing surface texture, enhancing mechanical properties, and preparing the steel for further processing or end-use, the skin pass mill solidifies its position as a quintessential element in modern metallurgy.

Authoritativeness stems from the 1250 skin pass mill's proven track record in enhancing steel properties. Notably, the process can significantly improve steel's ductility, reducing potential brittleness that could lead to material failure. By achieving a desirable balance between strength and flexural properties, the skin pass process underpins the authoritative stance of these mills in ensuring structural integrity. Industries rely heavily on these benefits for constructing robust, long-lasting products that stand the test of time. Trustworthiness of the 1250 skin pass mill is further bolstered by its contribution to quality assurance processes. Through careful calibration and adherence to standards, producers can guarantee consistency in product quality. This reliability not only minimizes wastage and reprocessing costs but also strengthens relationships with clients who demand only the best for their end products. In summary, the 1250 skin pass mill embodies the synthesis of experience, expertise, authoritativeness, and trustworthiness in the steel production arena. By enabling superior product quality and robust manufacturing processes, it secures its essential status in advancing global industrial standards. Whether for new applications or ensuring time-honored steel properties, it remains an indispensable tool for achieving excellence in the metalworking field.

Authoritativeness stems from the 1250 skin pass mill's proven track record in enhancing steel properties. Notably, the process can significantly improve steel's ductility, reducing potential brittleness that could lead to material failure. By achieving a desirable balance between strength and flexural properties, the skin pass process underpins the authoritative stance of these mills in ensuring structural integrity. Industries rely heavily on these benefits for constructing robust, long-lasting products that stand the test of time. Trustworthiness of the 1250 skin pass mill is further bolstered by its contribution to quality assurance processes. Through careful calibration and adherence to standards, producers can guarantee consistency in product quality. This reliability not only minimizes wastage and reprocessing costs but also strengthens relationships with clients who demand only the best for their end products. In summary, the 1250 skin pass mill embodies the synthesis of experience, expertise, authoritativeness, and trustworthiness in the steel production arena. By enabling superior product quality and robust manufacturing processes, it secures its essential status in advancing global industrial standards. Whether for new applications or ensuring time-honored steel properties, it remains an indispensable tool for achieving excellence in the metalworking field.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products