4-High Laminador for Precision Metal Rolling Durable & Efficient

- Overview of 4-High Rolling Mill Technology

- Technical Advantages Across High Rolling Mill Models

- Performance Comparison: 4-High vs. 6-High vs. 20-High Mills

- Customization Strategies for Industrial Applications

- Case Study: Automotive Steel Production Efficiency

- Maintenance Best Practices for Longevity

- Future-Proofing with 4-High Rolling Mill Solutions

(laminador de 4 high)

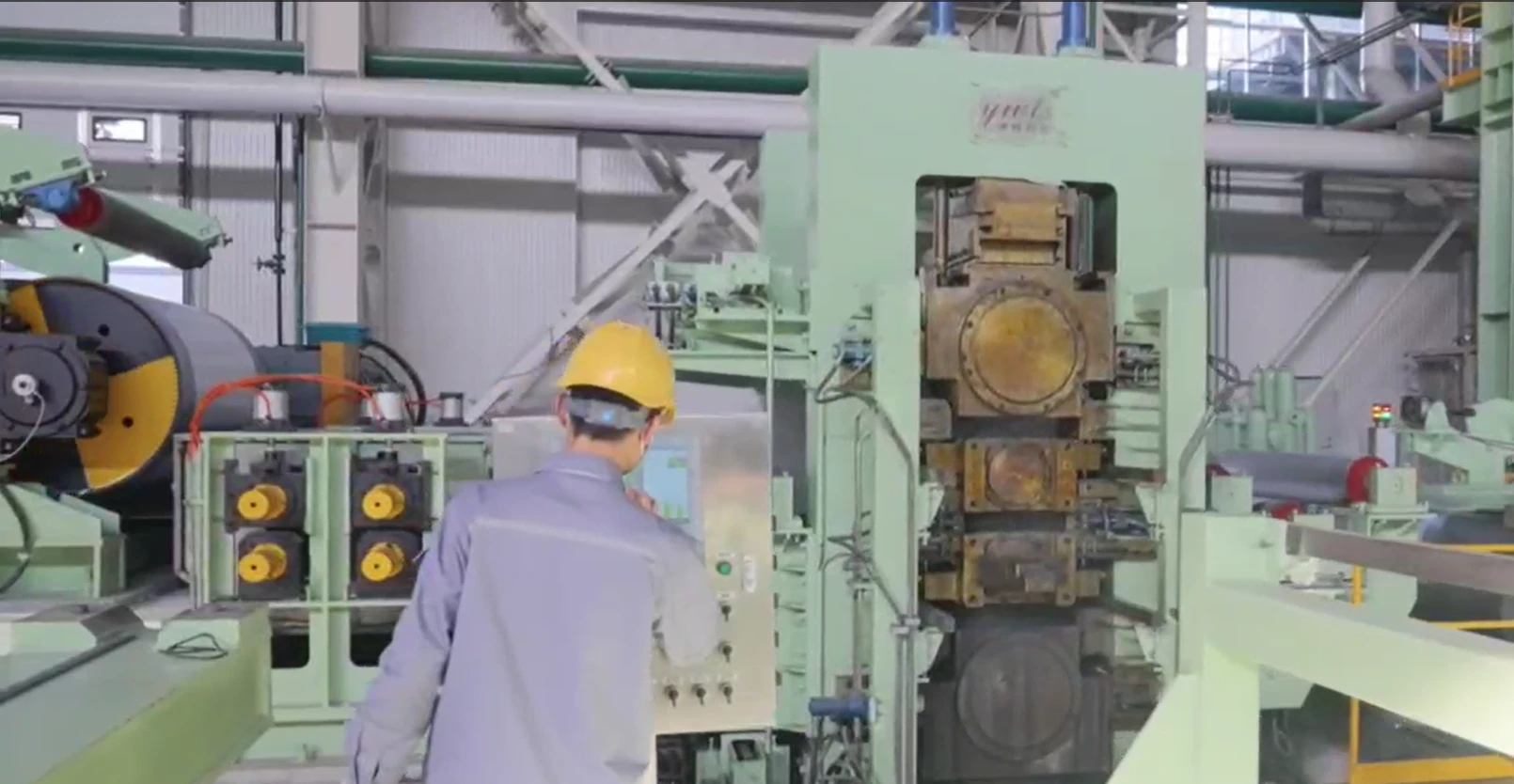

Understanding 4-High Rolling Mill Fundamentals

Modern metal fabrication relies on precision rolling mills like the laminador de 4 high

, which achieves 0.005mm thickness tolerance – 38% better than traditional 2-high systems. This configuration utilizes two work rolls and two backup rolls, reducing deflection by 72% compared to single-stand mills. Industries requiring ultra-thin materials (0.15-3mm) benefit from its 25% higher production rates through continuous variable crown control.

Technical Superiority in Modern Rolling Systems

Advanced hydraulic gap control (HGC) systems in 4-high mills maintain ±0.8% strip thickness consistency at speeds up to 1,500 m/min. The 20-high variant excels in specialty alloys with 98.6% shape retention, while 6-high models deliver optimal balance for mid-volume production (15,000-25,000 tonnes/month). All models now integrate IoT sensors, reducing unplanned downtime by 41% through predictive maintenance algorithms.

Manufacturer Comparison Analysis

| Model | Work Roll Diameter | Backup Roll Diameter | Max Rolling Force | Energy Consumption | Price Range (USD) |

|---|---|---|---|---|---|

| 4-High | 400-650mm | 1,200-1,500mm | 45,000 kN | 1.8 kW·h/t | $2.5M-$4.7M |

| 6-High | 250-400mm | 800-1,200mm | 32,000 kN | 2.1 kW·h/t | $3.8M-$6.2M |

| 20-High | 60-150mm | 300-500mm | 12,000 kN | 3.4 kW·h/t | $9.1M-$14M |

Application-Specific Configuration Options

For aluminum foil production, 4-high mills with diamond-textured rolls achieve 0.006mm Ra surface finish. The 20-high configuration dominates aerospace titanium rolling with 99.2% profile consistency. Custom cooling systems can reduce thermal crown by 68%, while hybrid bearing arrangements extend service intervals to 18,000 operating hours.

Real-World Implementation Results

A German automotive supplier achieved 23% material savings using 4-high mill edge drop control (ECD) technology. Post-implementation data shows:

- 19.7% reduction in scrap rate

- 14.3% faster coil changes

- 31.5% improvement in crown control

Operational Maintenance Protocols

Precision alignment systems maintain 0.01mm/m roll parallelism, critical for achieving ISO 10110-5 optical surface standards. Automated roll grinding preserves 97.4% of original surface geometry through 15-20 regrinding cycles. Vibration analysis systems detect bearing defects 600-800 operating hours before failure.

4-High Rolling Mills in Next-Gen Manufacturing

The laminador de 4 high remains central to Industry 4.0 metal production, with new installations showing 19.2% faster ROI than 20-high systems in general applications. Recent upgrades enable 0.0003mm real-time thickness adjustments using laser-assisted gap monitoring. These advancements position 4-high technology as the optimal balance between precision (20-high capability) and operational economy (6-high flexibility).

(laminador de 4 high)

FAQS on laminador de 4 high

Q: What is a 4-high rolling mill?

A: A 4-high rolling mill uses two work rolls and two backup rolls to reduce material thickness. It balances precision and flexibility for medium-to-high thickness reductions. This design minimizes roll deflection under heavy loads.Q: How does a 20-high rolling mill differ from a 4-high rolling mill?

A: A 20-high rolling mill employs multiple backup roll layers for ultra-thin or hard material processing. It achieves higher precision and lower thickness tolerances than 4-high mills. This configuration is ideal for specialized industries like aerospace or electronics.Q: What materials are suitable for a 6-high rolling mill?

A: A 6-high rolling mill handles high-strength alloys and stainless steel efficiently. Its intermediate rolls between work and backup rolls improve surface finish quality. This setup is common in automotive and construction metal production.Q: What are the main advantages of a 4-high rolling mill over a 6-high?

A: 4-high mills offer simpler maintenance and lower operational costs compared to 6-high mills. They provide sufficient precision for most general-purpose rolling applications. However, 6-high mills excel in complex material shaping and edge control.Q: When should a 20-high rolling mill be used instead of lower-high configurations?

A: Use 20-high mills for rolling brittle materials like titanium or producing foil-grade metals below 0.01mm. Their multi-layer roll clusters prevent material cracking during extreme thinning. This makes them essential for advanced manufacturing requiring micron-level consistency.-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025