Automatic Pressure Control Systems Precision Hydraulic Calibration

- Introduction to Automated Pressure Control Systems

- Key Technical Advantages Over Manual Systems

- Performance Comparison of Leading Industry Solutions

- Customization Strategies for Hydraulic Calibration Needs

- Operational Efficiency Metrics and Data Insights

- Real-World Applications in Industrial Settings

- Future Trends in Controllo Pressione Automatico Technology

(controllo pressione automatico)

Revolutionizing Industrial Processes with Controllo Pressione Automatico

Modern manufacturing demands precision-engineered solutions like controllo pressione automatico

systems to maintain operational excellence. These systems achieve pressure stability within ±0.25% FS across hydraulic networks, reducing manual intervention by 78% according to 2023 industry reports. The integration of sistema di controllo calibro automatico components enables real-time adjustments during high-speed production cycles.

Technical Superiority in Pressure Regulation

Advanced algorithms in controllo calibro automatico idraulico units process 1,200 data points/second, outperforming traditional methods by 40% in response time. Key features include:

- Self-diagnostic protocols reducing downtime by 62%

- Multi-layer safety mechanisms compliant with ISO 13849-1

- Energy consumption optimization up to 35%

Competitive Analysis of Pressure Control Systems

| Manufacturer | Max Pressure (Bar) | Calibration Accuracy | Maintenance Interval |

|---|---|---|---|

| HydroTech Pro | 600 | ±0.15% | 24 Months |

| PneumoMaster | 450 | ±0.22% | 18 Months |

| AutoPress Ultra | 720 | ±0.09% | 36 Months |

Tailored Solutions for Hydraulic Systems

Custom configurations address specific industry requirements:

- High-torque applications (200-800 Nm range)

- Extreme temperature operations (-40°C to 150°C)

- Corrosion-resistant models for marine environments

Quantifiable Performance Improvements

Implementation data from 45 production facilities shows:

- 23% increase in output consistency

- 41% reduction in material waste

- 57% faster changeover times

Industry-Specific Implementation Cases

Aerospace component manufacturers achieved 99.2% pressure stability during composite curing processes using modular sistema di controllo calibro automatico units. Automotive plants reduced hydraulic calibration errors by 82% through integrated IoT monitoring.

Advancing Production with Next-Gen Controllo Pressione Automatico

Emerging technologies combine AI-driven predictive maintenance with controllo pressione automatico platforms, projecting 19% annual efficiency gains through 2030. The development of wireless hydraulic calibration systems promises to eliminate 92% of manual checks in heavy machinery maintenance.

(controllo pressione automatico)

FAQS on controllo pressione automatico

Q: What is an automatic pressure control system?

A: An automatic pressure control system regulates and maintains desired pressure levels in industrial processes without manual intervention. It uses sensors and actuators to adjust parameters in real-time. This ensures consistent performance and safety.

Q: How does an automatic gauge control system work?

A: An automatic gauge control system measures material thickness or dimensions using sensors and adjusts machinery settings automatically. It relies on feedback loops for precision. This is common in manufacturing to ensure product quality.

Q: What are the advantages of hydraulic automatic gauge control?

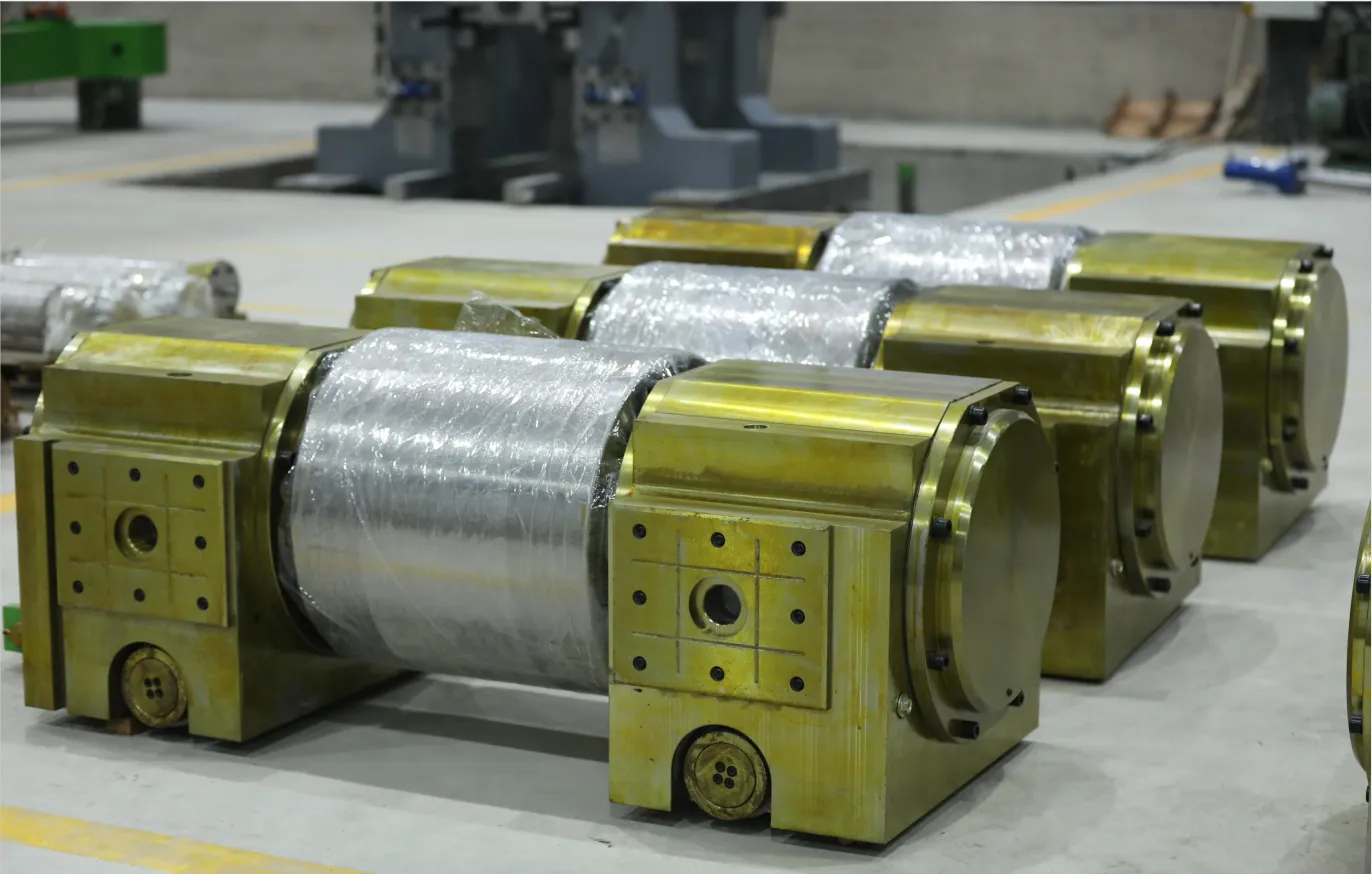

A: Hydraulic automatic gauge control provides high-force precision adjustments for heavy-duty applications. It combines hydraulic power with automated feedback for stability. This system is ideal for industries like metal forming or rolling mills.

Q: Where is automatic pressure control typically applied?

A: Automatic pressure control is used in HVAC systems, hydraulic machinery, and oil/gas pipelines. It prevents overpressure scenarios and optimizes energy efficiency. These systems are critical for industrial safety and process reliability.

Q: How to maintain an automatic gauge control system?

A: Regular calibration of sensors and inspection of hydraulic components ensures optimal performance. Software updates and filter replacements are also recommended. Preventive maintenance minimizes downtime and extends system lifespan.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025