automatic gauge control cold rolling mill

يناير . 14, 2025 10:11

Back to list

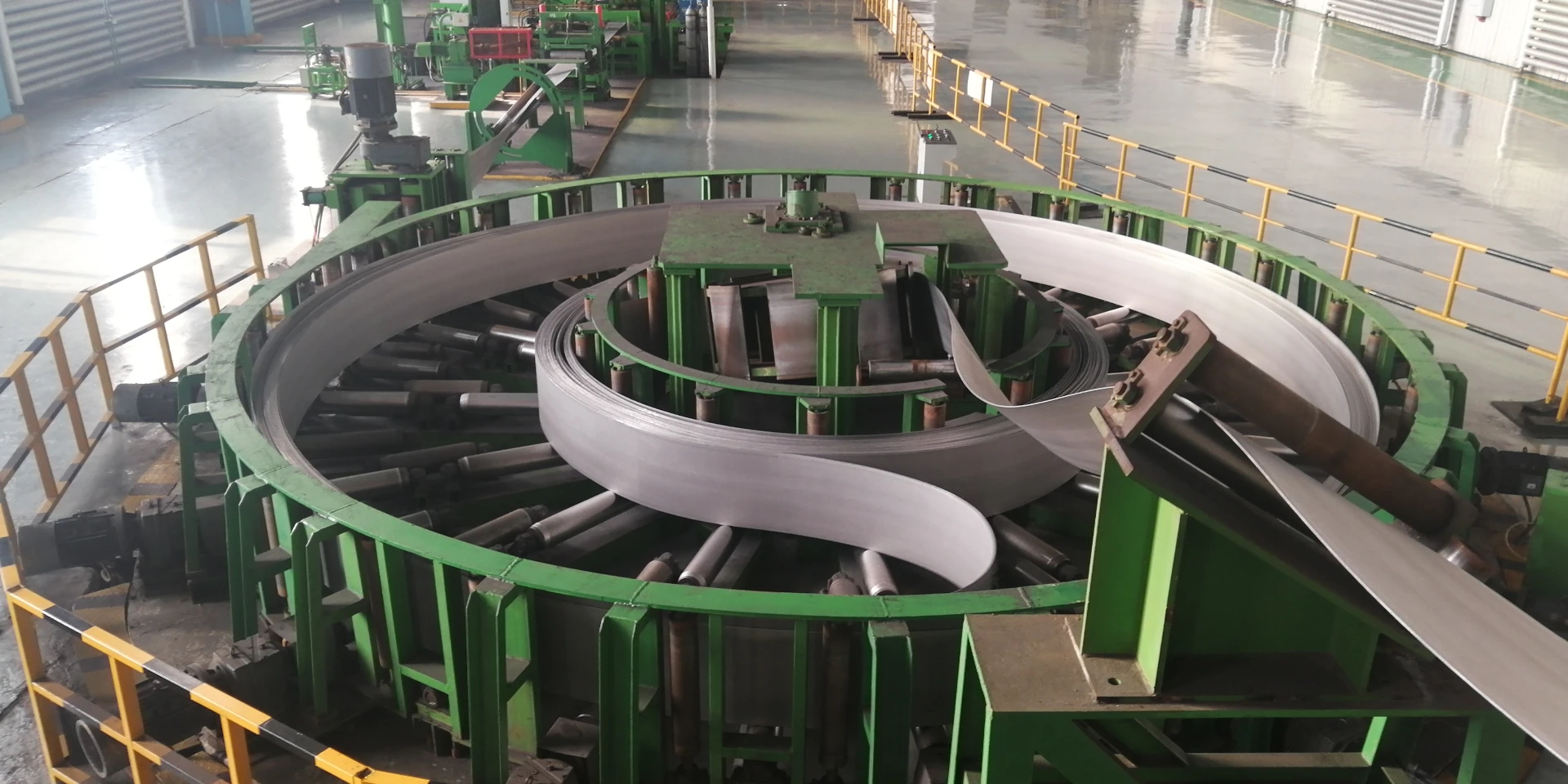

automatic gauge control cold rolling mill

The copper rolling machine stands as a revolutionary component in the world of metalworking, blending decades of engineering sophistication with modern technological advancements. As industries evolve, the demand for seamless and efficient copper products surges, making these machines indispensable. Their unparalleled ability to transform raw copper into refined sheets or bars is a testament to their engineering brilliance.

The credibility of a copper rolling machine is further accentuated by its adherence to stringent quality control measures. Manufacturers of these machines implement rigorous testing phases and subscribe to international standards such as ISO certifications, ensuring every unit delivered is reliable and efficient. Machine providers often avail warranties and service contracts which speak volumes about their confidence in the machine’s durability and performance. Trustworthiness in the copper rolling equipment sector is also built on a foundation of user testimonials and industry accolades. Real-world applications and client satisfaction stories play a pivotal role in establishing the reputation of a manufacturer's machinery. Enterprises considering investment in copper rolling machines are encouraged to evaluate industry reviews, technology advancements, and after-sales support offered by sellers. The copper rolling machine is more than an industrial necessity; it is an emblem of technological advancement, requiring exceptional engineering, profound expertise, authenticity, and reliability. Its undeniable contribution to enhancing product quality and operational efficiency makes it a cornerstone in the copper production process.

The credibility of a copper rolling machine is further accentuated by its adherence to stringent quality control measures. Manufacturers of these machines implement rigorous testing phases and subscribe to international standards such as ISO certifications, ensuring every unit delivered is reliable and efficient. Machine providers often avail warranties and service contracts which speak volumes about their confidence in the machine’s durability and performance. Trustworthiness in the copper rolling equipment sector is also built on a foundation of user testimonials and industry accolades. Real-world applications and client satisfaction stories play a pivotal role in establishing the reputation of a manufacturer's machinery. Enterprises considering investment in copper rolling machines are encouraged to evaluate industry reviews, technology advancements, and after-sales support offered by sellers. The copper rolling machine is more than an industrial necessity; it is an emblem of technological advancement, requiring exceptional engineering, profound expertise, authenticity, and reliability. Its undeniable contribution to enhancing product quality and operational efficiency makes it a cornerstone in the copper production process.

Next:

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products