Agc System For Hot/Cold Strip Rolling Mill

يناير . 13, 2025 13:34

Back to list

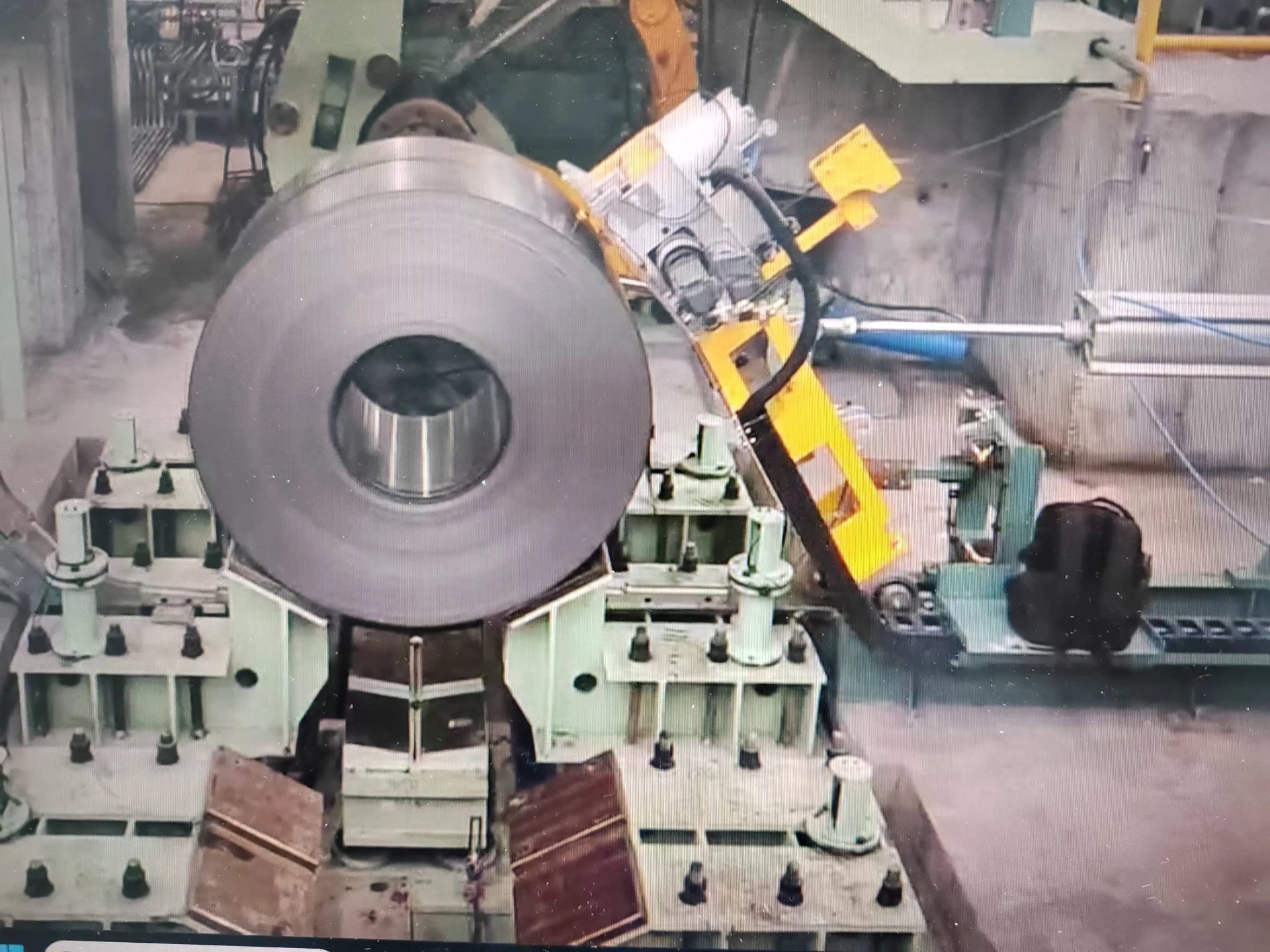

Agc System For Hot/Cold Strip Rolling Mill

In the expansive world of industrial manufacturing, the forging rolling mill stands as a testament to advanced engineering and manufacturing efficiency. These sophisticated machines are essential for transforming raw metal into high-quality, precise products, serving as a critical component in various industries, ranging from automotive to aerospace.

In terms of authoritativeness, the forging rolling mill has a storied reputation, often being highlighted in academic journals and industry conferences. Experts in material science and engineering frequently reference these mills in discussions about advancements in rolled product quality and efficiency. Institutions and corporations invest heavily in research and development to push the boundaries of what's possible with forging rolling technology. This authoritative presence is further reinforced by the patents and innovations that stem from this sector, which serve as benchmarks for excellence in manufacturing technology. Trustworthiness is inherently linked to the safety, repeatability, and reliability of the forging rolling mill. Manufacturers prioritize the incorporation of safety features that protect operators and ensure consistent production quality. Regular maintenance schedules and the use of high-grade materials in construction underline the trustworthiness of these machines. End-users, from automotive giants to aerospace contractors, rely on these mills to produce components that meet stringent safety and performance standards. The consistent delivery of high-quality products builds trust that these machines will perform under demanding conditions without fail. In conclusion, the forging rolling mill is not just a piece of industrial equipment; it is a symbol of engineering prowess and innovation. It embodies a legacy of knowledge, precision, and reliability that continues to evolve, meeting the changing demands of modern industry. Its role in the production chain is undeniable, offering unparalleled quality and efficiency, driven by a commitment to excellence in manufacturing.

In terms of authoritativeness, the forging rolling mill has a storied reputation, often being highlighted in academic journals and industry conferences. Experts in material science and engineering frequently reference these mills in discussions about advancements in rolled product quality and efficiency. Institutions and corporations invest heavily in research and development to push the boundaries of what's possible with forging rolling technology. This authoritative presence is further reinforced by the patents and innovations that stem from this sector, which serve as benchmarks for excellence in manufacturing technology. Trustworthiness is inherently linked to the safety, repeatability, and reliability of the forging rolling mill. Manufacturers prioritize the incorporation of safety features that protect operators and ensure consistent production quality. Regular maintenance schedules and the use of high-grade materials in construction underline the trustworthiness of these machines. End-users, from automotive giants to aerospace contractors, rely on these mills to produce components that meet stringent safety and performance standards. The consistent delivery of high-quality products builds trust that these machines will perform under demanding conditions without fail. In conclusion, the forging rolling mill is not just a piece of industrial equipment; it is a symbol of engineering prowess and innovation. It embodies a legacy of knowledge, precision, and reliability that continues to evolve, meeting the changing demands of modern industry. Its role in the production chain is undeniable, offering unparalleled quality and efficiency, driven by a commitment to excellence in manufacturing.

Next:

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products