عملية مطحنة تمرير الجلد

فبراير . 19, 2025 05:35

Back to list

عملية مطحنة تمرير الجلد

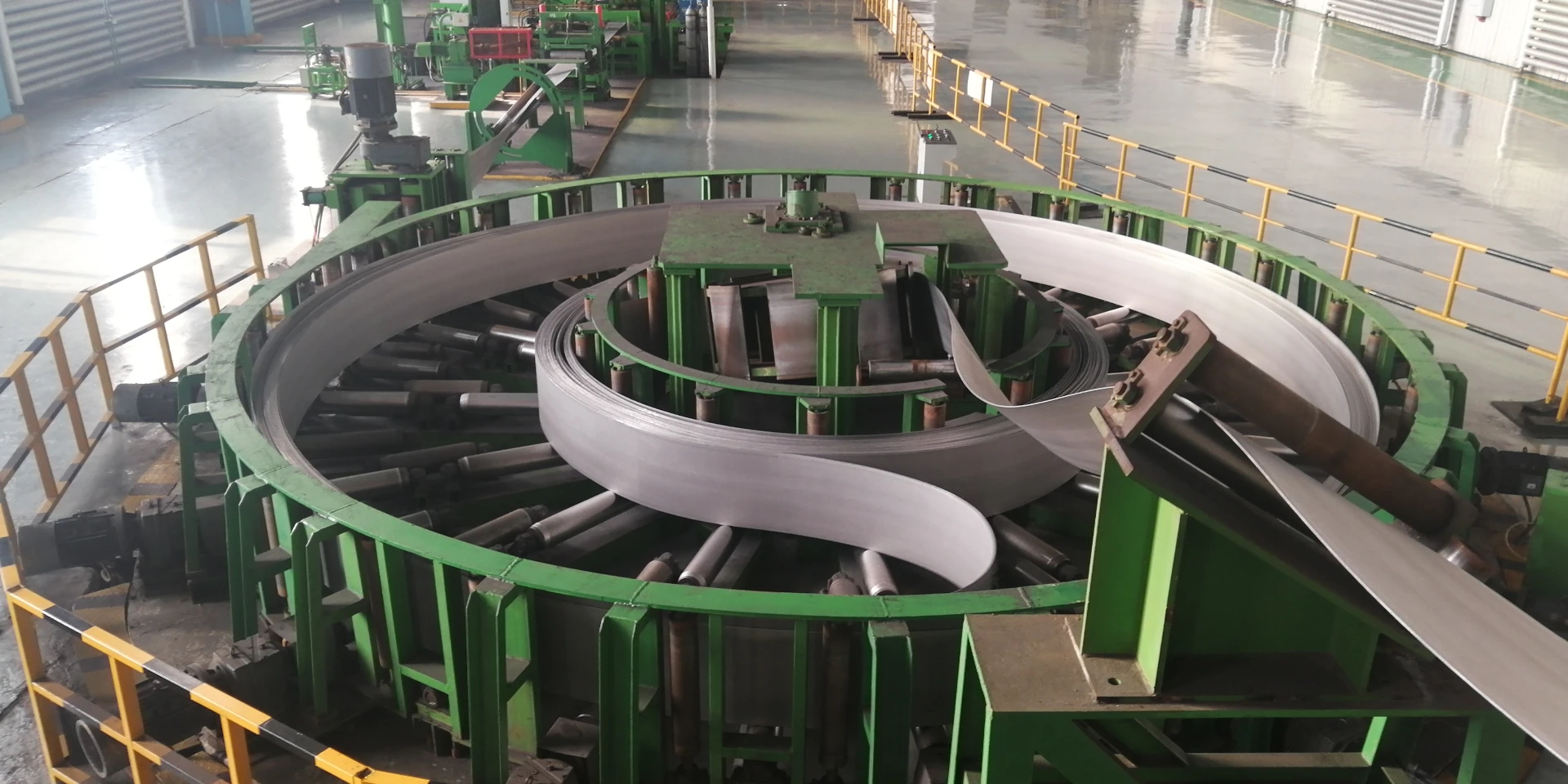

Skin pass rolling, often referred to as skin pass mill operation, is a crucial process in the steel and metal finishing industry, enhancing the surface quality and mechanical properties of the rolled products. The process, carried out in a specialized mill known as the skin pass mill, plays an essential role in meeting the stringent demands of modern engineering applications.

Trust in skin pass rolling processes is built through a combination of consistent quality and reliable production outcomes. Manufacturers achieve this by implementing meticulous quality control processes and leveraging state-of-the-art technology. This includes using advanced sensors and diagnostic tools to monitor the rolling process in real-time, ensuring any discrepancies are immediately addressed. Authoritative companies in the field often invest heavily in research and development, exploring novel ways to integrate cutting-edge technologies such as artificial intelligence and machine learning into the skin pass milling operation. These technologies have the potential to revolutionize traditional methodologies—enhancing precision, reducing waste, and increasing overall efficiency. Moreover, a commitment to sustainability in skin pass rolling operations further strengthens a manufacturer’s credibility. By innovating new eco-friendly rolling techniques and reducing energy consumption, these companies demonstrate a profound responsibility towards the environment. This commitment builds trust with environmentally-conscious consumers and clients, reinforcing the integrity of the manufacturing process. In conclusion, skin pass rolling is not merely a process but a specialized art form requiring a high level of expertise, authority, and trustworthiness. It combines meticulous technique, in-depth knowledge, and cutting-edge technology to produce superior metal products. As industries evolve, the role of skin pass rolling in delivering precise and high-quality results becomes even more critical, reflecting the ongoing advancement and innovation within the field.

Trust in skin pass rolling processes is built through a combination of consistent quality and reliable production outcomes. Manufacturers achieve this by implementing meticulous quality control processes and leveraging state-of-the-art technology. This includes using advanced sensors and diagnostic tools to monitor the rolling process in real-time, ensuring any discrepancies are immediately addressed. Authoritative companies in the field often invest heavily in research and development, exploring novel ways to integrate cutting-edge technologies such as artificial intelligence and machine learning into the skin pass milling operation. These technologies have the potential to revolutionize traditional methodologies—enhancing precision, reducing waste, and increasing overall efficiency. Moreover, a commitment to sustainability in skin pass rolling operations further strengthens a manufacturer’s credibility. By innovating new eco-friendly rolling techniques and reducing energy consumption, these companies demonstrate a profound responsibility towards the environment. This commitment builds trust with environmentally-conscious consumers and clients, reinforcing the integrity of the manufacturing process. In conclusion, skin pass rolling is not merely a process but a specialized art form requiring a high level of expertise, authority, and trustworthiness. It combines meticulous technique, in-depth knowledge, and cutting-edge technology to produce superior metal products. As industries evolve, the role of skin pass rolling in delivering precise and high-quality results becomes even more critical, reflecting the ongoing advancement and innovation within the field.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products