seasoning packaging machine

فبراير . 04, 2025 02:57

Back to list

seasoning packaging machine

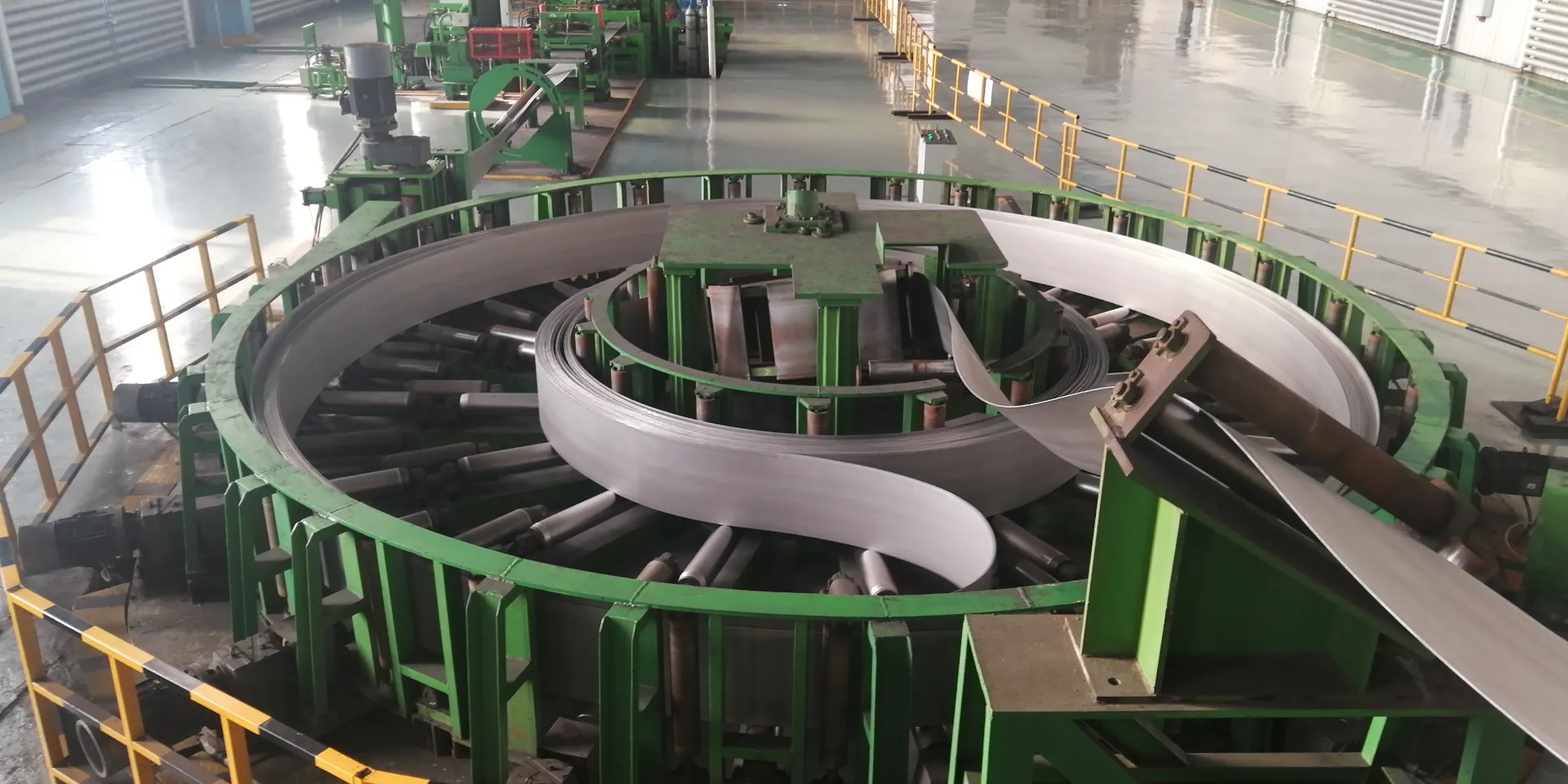

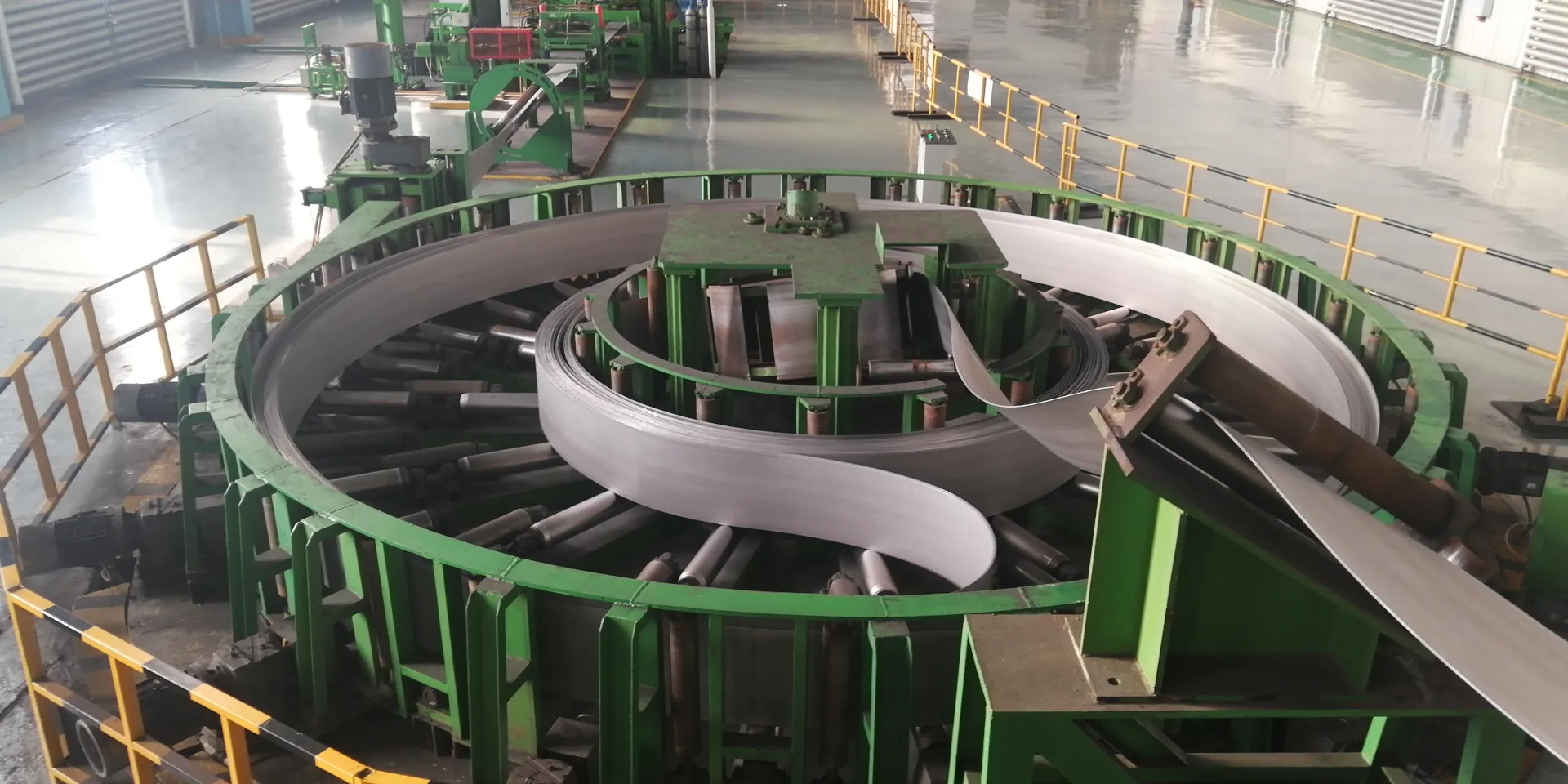

Cold rolled steel strips, also known as نوار نورد سرد in Persian, represent a critical component in various industrial sectors due to their superior surface finish, tighter tolerances, and enhanced mechanical properties. This product derives its increasing relevance from its role in providing high precision for applications that demand superior quality.

From an authoritative perspective, cold rolled steel strips are often juxtaposed with other materials like hot rolled steel, owing to their distinct composition and finish, making them an industry standard for high-grade applications. Regulatory bodies often stipulate stringent standards, such as the ASTM standards in the US, to which manufacturers must adhere, confirming the authoritative status these materials hold across global markets. Last but not least, the trustworthiness of cold rolled steel strips stems from their enhanced durability and precision in performance. Various engineering assessments consistently underscore their ability to uphold structural performance under diverse operational conditions. This aspect is particularly significant for sectors such as construction and automotive, where material failure can lead to catastrophic consequences. Thus, adherence to international standards during production processes ensures these strips fulfill both functional and safety expectations. In summary, cold rolled steel strips stand out as a fundamental material across various industry applications, attributed to their enhanced surface quality, precision engineering, and reliability under high-stress conditions. Stakeholders across the manufacturing spectrum continually advocate for their use, given the strategic advantages they provide in creating high-quality, dependable end products. This trust built over years, backed by consistent material performance and compliance with international standards, fortifies their position as a preferred choice amongst industry professionals.

From an authoritative perspective, cold rolled steel strips are often juxtaposed with other materials like hot rolled steel, owing to their distinct composition and finish, making them an industry standard for high-grade applications. Regulatory bodies often stipulate stringent standards, such as the ASTM standards in the US, to which manufacturers must adhere, confirming the authoritative status these materials hold across global markets. Last but not least, the trustworthiness of cold rolled steel strips stems from their enhanced durability and precision in performance. Various engineering assessments consistently underscore their ability to uphold structural performance under diverse operational conditions. This aspect is particularly significant for sectors such as construction and automotive, where material failure can lead to catastrophic consequences. Thus, adherence to international standards during production processes ensures these strips fulfill both functional and safety expectations. In summary, cold rolled steel strips stand out as a fundamental material across various industry applications, attributed to their enhanced surface quality, precision engineering, and reliability under high-stress conditions. Stakeholders across the manufacturing spectrum continually advocate for their use, given the strategic advantages they provide in creating high-quality, dependable end products. This trust built over years, backed by consistent material performance and compliance with international standards, fortifies their position as a preferred choice amongst industry professionals.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products