Energy Efficiency in Reversing Cold Rolling Mills

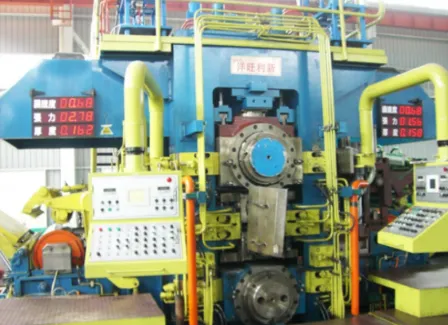

The steel industry is under increasing pressure to enhance energy efficiency while maintaining high production standards. Among the various types of rolling mills, the reversing cold rolling mill plays a crucial role in producing high-precision steel strips with superior surface quality. Unlike continuous rolling mills, a reversible cold rolling mill processes metal sheets in multiple passes by reversing the direction of rolling, allowing for precise thickness control. However, this process is traditionally energy-intensive due to frequent acceleration and deceleration. As sustainability becomes a priority, manufacturers are focusing on improving the energy efficiency of reversing cold mills through advanced technologies, optimized processes, and innovative design modifications.

Energy Consumption Challenges in Reversing Rolling Mills

A cold reversing mill consumes significant amounts of electricity due to its operational nature. The repeated starting, stopping, and reversing of the rolls require high torque from drive systems, leading to substantial energy losses. Additionally, auxiliary systems such as lubrication, cooling, and tension control further contribute to power consumption. In conventional reversible rolling mills, nearly 30-40% of the total energy input is wasted as heat, mechanical friction, and inefficient motor operations. Addressing these inefficiencies is critical for reducing operational costs and minimizing the environmental impact of steel production.

Advanced Drive Systems for Energy Savings in Reversing Rolling Mills

One of the most effective ways to enhance energy efficiency in reversing cold rolling mills is through the adoption of advanced drive technologies. Modern mills now utilize regenerative drives that recover and reuse braking energy during deceleration. Instead of dissipating energy as heat, these systems convert kinetic energy back into electrical power, feeding it into the plant’s grid. Variable frequency drives (VFDs) are also widely implemented to optimize motor speed according to load requirements, reducing unnecessary power consumption. Furthermore, permanent magnet synchronous motors (PMSMs) are gaining popularity due to their higher efficiency compared to traditional induction motors. These innovations collectively contribute to a 15-25% reduction in energy usage in reversible cold rolling mills.

Process Optimization and Automation of Reversing Rolling Mills

Automation plays a pivotal role in minimizing energy waste in reversing cold mills. Advanced process control systems, powered by artificial intelligence and machine learning, optimize rolling parameters in real time. By analyzing data from previous passes, these systems adjust rolling force, speed, and tension to achieve the desired strip thickness with minimal energy expenditure. Predictive maintenance tools also help in reducing unplanned downtimes, ensuring that the mill operates at peak efficiency. Additionally, modern cold reversing mills incorporate dynamic gap control systems that adjust roll gaps precisely, reducing redundant deformation work and lowering power consumption.

Lubrication and Cooling System Improvements of Reversing Rolling Mills

The lubrication and cooling systems in a reversible rolling mill are essential for maintaining product quality but can be energy-intensive if not optimized. Traditional flood lubrication methods are being replaced with minimum quantity lubrication (MQL) systems, which apply a controlled amount of lubricant directly to the roll-strip interface. This not only reduces friction but also decreases the energy required for pumping and filtering excess coolant. Advanced emulsion cooling systems with precise temperature control further enhance efficiency by minimizing thermal losses. These improvements lead to a more sustainable operation while extending the lifespan of rolling mill components.

Material and Design Innovations in Reversing Rolling Mills

The structural design of reversing cold rolling mills has evolved to reduce energy losses. Lightweight yet high-strength materials are now used in roll construction to decrease inertia, allowing faster acceleration and deceleration with lower energy input. Additionally, the integration of hybrid roll bearings, which combine hydrodynamic and rolling element bearings, reduces frictional losses significantly. Another emerging trend is the use of nanostructured coatings on rolls, which enhance wear resistance and reduce the need for frequent regrinding, indirectly contributing to energy savings.

Future Trends and Sustainable Practices of Reversing Rolling Mills

The future of reversible cold rolling mills lies in further integration with renewable energy sources and smart grid technologies. Some steel plants are experimenting with solar or wind-powered rolling mills to offset electricity consumption. Digital twin technology is also being explored to simulate and optimize mill operations before physical implementation, ensuring maximum energy efficiency. As regulatory pressures and energy costs rise, the adoption of these innovations will become increasingly critical for the competitiveness of steel manufacturers.

Energy efficiency in reversing cold rolling mills is no longer an optional consideration but a necessity for sustainable steel production. Through advanced drive systems, process automation, optimized lubrication, and innovative mill designs, significant energy savings can be achieved. As technology continues to evolve, the reversible rolling mill of the future will be smarter, more efficient, and aligned with global sustainability goals. Manufacturers investing in these advancements today will not only reduce operational costs but also contribute to a greener industrial landscape.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025