Agc System For Hot/Cold Strip Rolling Mill

Фев . 20, 2025 12:09

Back to list

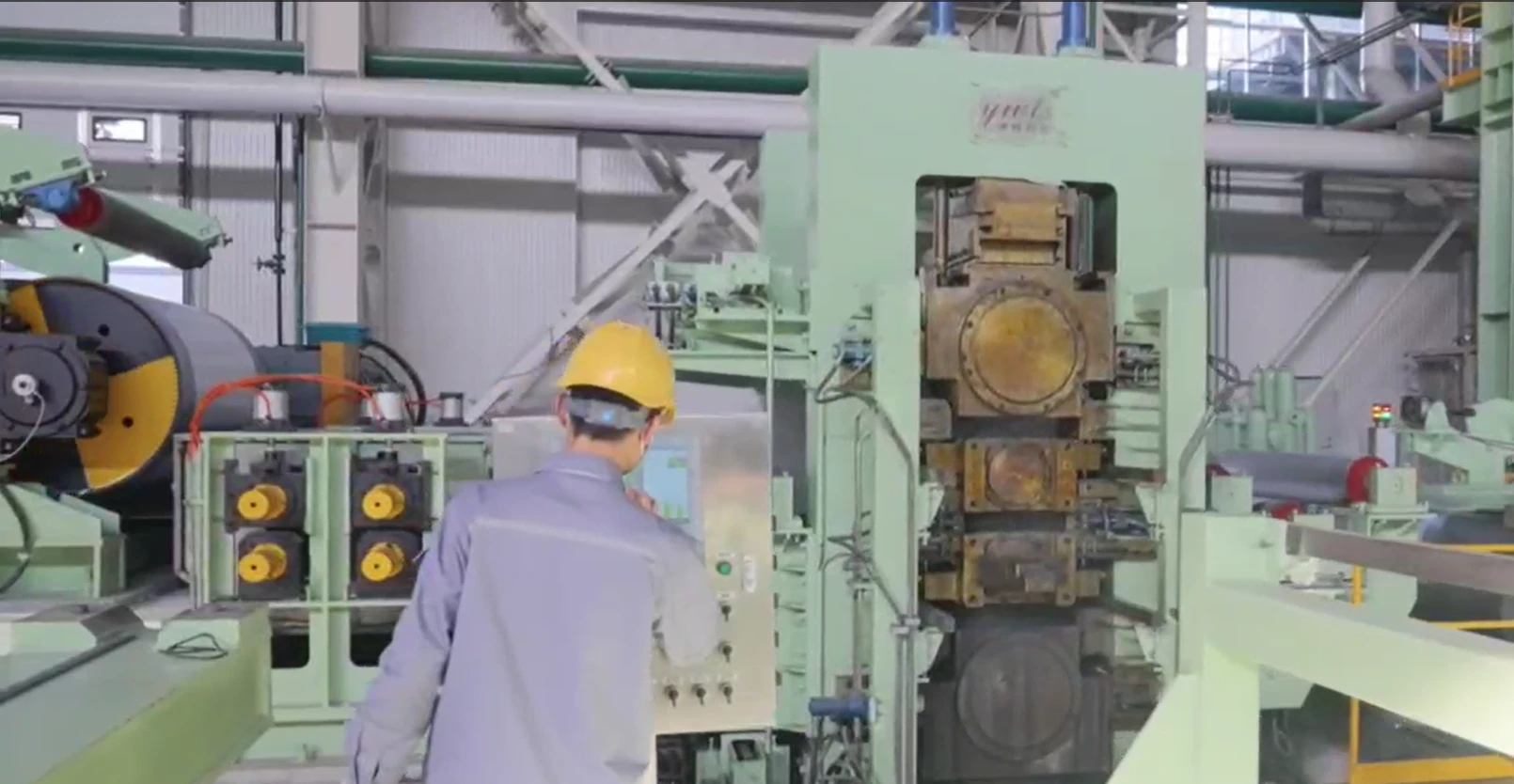

Agc System For Hot/Cold Strip Rolling Mill

The skin-pass rolling process stands at the frontier of advanced material processing techniques, essential for refining the surface quality of metals, particularly steel. This technique, pivotal within the metallurgical realm, is renowned for enhancing surface texture, homogenizing mechanical properties, and optimizing the final product for subsequent coating processes. Unlike conventional rolling practices, the skin-pass process integrates a sophisticated blend of minimal thickness reduction and an elevated focus on surface refinement, ensuring products exhibit superior aesthetic and mechanical attributes.

Documentation of real-world applications through case studies illustrates the transformative impact of the skin-pass process. For instance, automotive part manufacturers utilizing this technique report marked improvements in production efficiencies coupled with an increase in the resiliency and quality of the end products. Such empirical evidence cements the trustworthiness of the skin-pass rolling process, validating its reputation as a cornerstone in the metallurgy field. As an expert, understanding the nuances of the skin-pass process is essential for those looking to refine and enhance metal properties effectively. The process entails precise control over rolling force and speed, an intricate balance that requires both technical skill and experience. This multifaceted approach ensures a product that not only meets the desired mechanical specifications but also excels in aesthetic appeal. The role of innovation in advancing this process cannot be overlooked. Recent advancements in automatic control systems and surface inspection technologies complement the skin-pass rolling process by allowing for real-time adjustments and quality assessments. These developments not only enhance operational efficiency but also fortify the reliability and consistency of the final product, key factors contributing to sustained consumer trust. In conclusion, the skin-pass rolling process represents the pinnacle of steel manufacturing, combining technical expertise with a commitment to quality and innovation. As industries continue to prioritize materials that offer both performance and aesthetic appeal, the demand for advanced methods like skin-pass rolling will only grow. By keeping pace with technological advancements and maintaining a rigorous focus on quality, manufacturers can continue to meet and surpass industry expectations, reinforcing the indispensable role of this process in modern metallurgy.

Documentation of real-world applications through case studies illustrates the transformative impact of the skin-pass process. For instance, automotive part manufacturers utilizing this technique report marked improvements in production efficiencies coupled with an increase in the resiliency and quality of the end products. Such empirical evidence cements the trustworthiness of the skin-pass rolling process, validating its reputation as a cornerstone in the metallurgy field. As an expert, understanding the nuances of the skin-pass process is essential for those looking to refine and enhance metal properties effectively. The process entails precise control over rolling force and speed, an intricate balance that requires both technical skill and experience. This multifaceted approach ensures a product that not only meets the desired mechanical specifications but also excels in aesthetic appeal. The role of innovation in advancing this process cannot be overlooked. Recent advancements in automatic control systems and surface inspection technologies complement the skin-pass rolling process by allowing for real-time adjustments and quality assessments. These developments not only enhance operational efficiency but also fortify the reliability and consistency of the final product, key factors contributing to sustained consumer trust. In conclusion, the skin-pass rolling process represents the pinnacle of steel manufacturing, combining technical expertise with a commitment to quality and innovation. As industries continue to prioritize materials that offer both performance and aesthetic appeal, the demand for advanced methods like skin-pass rolling will only grow. By keeping pace with technological advancements and maintaining a rigorous focus on quality, manufacturers can continue to meet and surpass industry expectations, reinforcing the indispensable role of this process in modern metallurgy.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products