Hydraulic Tension Control Systems Precision & Durability

- Overview of Tension Control Systems in Modern Industries

- Critical Components: Hydraulic System Spare Parts

- Technical Advantages and Operational Efficiency

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Real-World Applications and Case Studies

- Future Trends in Tension Control System Optimization

(sistemas de control de tensión)

Overview of Tension Control Systems in Modern Industries

In today’s manufacturing landscape, sistemas de control de tensión

play a pivotal role in ensuring precision across industries like packaging, textiles, and metal processing. These systems regulate material tension during production, minimizing waste and enhancing product consistency. According to a 2023 market report, industries adopting advanced tension control solutions observe a 22% reduction in operational downtime and a 17% increase in throughput.

Critical Components: Hydraulic System Spare Parts

Hydraulic subsystems are integral to maintaining optimal tension control. High-quality repuestos de sistemas hidráulicos, such as valves, pumps, and actuators, ensure system longevity. For instance, replacing worn-out servo valves with precision-engineered spares can improve response times by 35%, as demonstrated in a recent case study by FluidTech Industries.

Technical Advantages and Operational Efficiency

Modern tension control systems leverage closed-loop feedback mechanisms and IoT integration to achieve real-time adjustments. Key benefits include:

- ±0.5% tension accuracy, compared to ±2.5% in traditional systems.

- Energy savings of up to 30% through adaptive load management.

- Predictive maintenance capabilities, reducing unplanned repairs by 40%.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Key Technology | Customization | Avg. Maintenance Cost (USD/year) |

|---|---|---|---|

| Bosch Rexroth | Electro-hydraulic hybrid | High | 12,500 |

| Parker Hannifin | Proportional valve systems | Moderate | 9,800 |

| Eaton | Smart PLC integration | Low | 14,200 |

Custom Solutions for Diverse Industrial Needs

Tailored tension control configurations address unique challenges. For example, a paper mill in Sweden achieved a 28% reduction in sheet breaks by integrating modular control de tensión units with variable-speed drives. Customization options include:

- Multi-zone tension profiling for wide-format machinery.

- Retrofit kits for legacy hydraulic systems.

- API-driven software interfaces for Industry 4.0 compatibility.

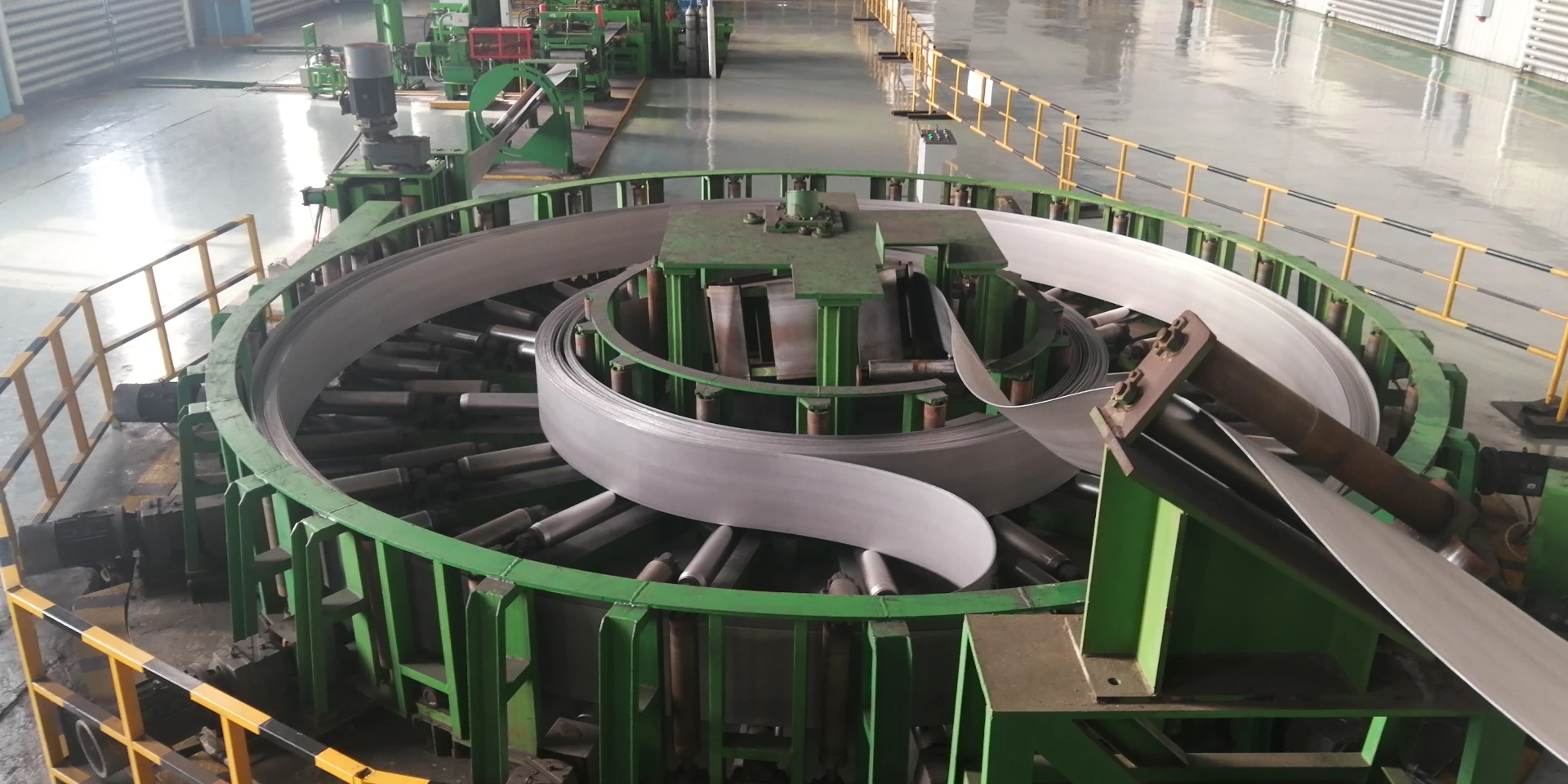

Real-World Applications and Case Studies

A automotive component manufacturer in Germany reduced material scrap by 19% after deploying IoT-enabled tension controllers. Similarly, a textile plant in India reported a 31% improvement in fabric alignment consistency using servo-driven hydraulic spares. These outcomes highlight the ROI potential of optimized systems.

Future Trends in Tension Control System Optimization

As industries prioritize sustainability, next-gen sistemas de control de tensión will integrate AI-powered diagnostics and carbon-neutral hydraulic fluids. Research from MIT indicates that adaptive algorithms could further reduce energy consumption by 45% by 2030, solidifying tension control as a cornerstone of efficient manufacturing.

(sistemas de control de tensión)

FAQS on sistemas de control de tensión

Q: What are the key components of tension control systems?

A: Tension control systems typically include load cells, rollers, brakes, clutches, and control units. These components work together to maintain consistent material tension in industrial processes like winding or unwinding. Hydraulic or pneumatic actuators may also be integrated for precision adjustments.

Q: How do hydraulic system spare parts improve tension control reliability?

A: High-quality hydraulic system spare parts, such as valves, pumps, and seals, ensure consistent fluid pressure and minimize leaks. Regular replacement of worn components prevents sudden tension fluctuations in production lines. This reduces downtime and maintains product quality in applications like paper or textile manufacturing.

Q: Why is calibration critical for tension control systems?

A: Calibration ensures sensors and controllers accurately measure and adjust tension forces. Uncalibrated systems may over-tighten or loosen materials, causing defects or breaks. Automated control systems often include self-diagnostic tools to simplify maintenance.

Q: Which industries benefit most from tension control technology?

A: Industries like packaging, printing, wire manufacturing, and converting rely heavily on tension control. Precise control prevents material stretching, wrinkling, or tearing during high-speed operations. Hydraulic and electric systems are chosen based on load requirements and operational precision.

Q: What causes tension fluctuations in control systems?

A: Fluctuations often stem from worn hydraulic components, sensor misalignment, or irregular material feed. Replacing damaged spare parts and ensuring proper system alignment can stabilize performance. Real-time monitoring software helps identify and resolve issues proactively.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025